Slovenian firm BeTec produces various slurry applicators and silage clamping tools … among other things. One machine that stands out is its latest offering, the Hyber Disc, a slurry applicator that replaces a trailing shoe arrangement with a disc injector.

KEEPING IT BRIEF

- Hyber Disc is a mixture of a trailing shoe and disc injector.

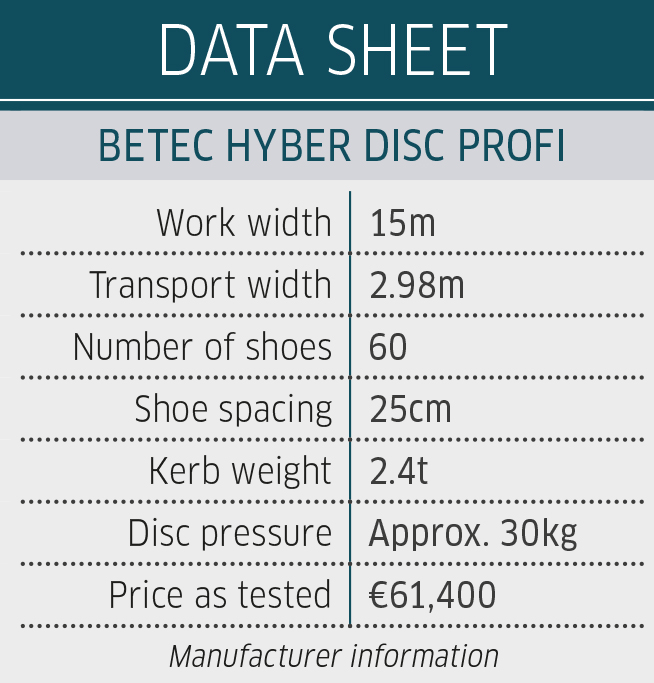

- The disc can have up to 30kg of downforce applied to it. Working widths of up to 24m are possible.

- The Hyber can also be used with umbilical hoses. It folds vertically behind the tanker.

- The featured 15m version weighs 2.4t.

Can you really combine the benefits of the lower weight of a trailing shoe with the optimum slurry placement of a disc injector even in dry soils? BeTec believes it has done precisely that, overcoming the drawback of disc injectors that are usually heavy in weight and have a limited working width. By comparison, trailing shoes are relatively lightweight and apply the slurry effectively.

The new concept from BeTec occupies the middle ground between the two applicator types. And while it may not be a household name here, the Slovenian manufacturer has been building trailing shoe booms for some time and is starting to make inroads into the German market.

Closer to home, the company has even been touting its wares in the UK as it looks to up its export potential.

From shoe to disc

The new Hyber Disc design sounds simple at first: the trailing shoes are replaced by 275mm diameter, 10mm thick discs in front of the rubber spout. However, due to the discs needing two bearings, one on either side for sturdier support, the leaf spring that usually carries the trailing shoe coulters was given a redesign.

What’s more, the middle frame including the boom is now sturdier, so that when the wings are unfolded they can be locked rigid. This means an even amount of weight can be applied to each of the springs, and, if this is not enough, you can even apply some additional pressure from the tanker.

According to BeTec, the machine we are looking at here, the vertically folding 15m heavy-duty ‘Pro’ version, weighs in at 2.4 tonnes. This should produce up to 30kg of coulter pressure and be able to press the 10mm wide disc into the ground.

Alternatively, BeTec offers a lighter version with a coulter pressure of just 20kg. The leaf spring splits at the base and has a small bend on the last 30mm so it can act as a depth limiter and scraper for the disc. The position of the rubber spout and hose can be adjusted with springs behind the cutting disc so they run parallel to the ground. A small metal ski clears out the slot, enabling the slurry to seep directly into the ground.

Clean slurry application

The Hyber Disc is just that, a hybrid between a shoe and disc injector. We were amazed at the pressure being applied to the disc. The injector comes into its own on hard, dry ground.

The spout runs parallel, applying the slurry in a clean, narrow band beneath the leaf, although It still remains to be seen whether the BeTec boom is sturdy enough to cope with the extra load from the discs.

Other details

- Gauge wheels are available as an option to support the boom.

- Each disc injector unit weighs about 6.5kg more than the trailing shoe.

- Maintenance-free, encapsulated bearings on the discs are also an option.

- Working widths of up to 24m are possible (these fold along the sides of the tanker).

- The Hyber Disc can also be used with umbilical systems.

- There’s no standard drip stop. However, an air-operated shut-off is offered.

- BeTec booms can also be retrofitted with the disc shoe. Each unit costs around €90.

- The light version with trailing shoes costs €40,000, while the disc injector variant is €45,400. The Profi (professional) version costs an additional €16,000.

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.