We all know by now the virtues of an umbilical setup – potential for a lighter footprint, enhanced nutrient monitoring, plus the potential for high outputs further contributes to the systems popularity. But how do you proceed if you want to set up a system with used equipment and is a mix of used and new a good idea?

Starting at the field end of the hose first, dribble bars remain the most widely used applicator for umbilical systems in the UK and Ireland due to their simplicity, ability to handle undulating terrain and durability. For those on a limited budget it is all too easy to look at the used applicator end but to not think through to how that applicator is supplied with liquid. If you expect to be able to set up an umbilical slurry or digestate handling system from scratch, using just used equipment, you may run into problems. The pool of viable used kit may not be as extensive as you might think.

Here we focus on equipment supplied by Suffolk-based Tramspread. The company manufactures and supplies parts and services for slurry and digestate management equipment, with bags of experience with umbilical systems. Indeed, a sister company offers a contracting service across East Anglia and beyond, running a large number of Tramspread umbilical systems.

This does not necessarily mean you can simply contact Tramspread and gain instant access to a variety of suitable used pumps and applicators. Umbilical slurry application remains a specialised sector and there are fewer systems in use when compared to tankers. Furthermore, there are numerous other factors to consider, including the type of pump best suited to the job, length and type of hose needed, alternative applicator options and the type of storage system and material being worked with. Obtaining reliable used equipment can be challenging, the more so if you just assume it will work.

If you are seeking to build a complete system from scratch it would be sensible to seek expert assistance which should include an appraisal of your existing slurry storage system. If on the other hand you only need a pump, spare hose reel, or an applicator to integrate into an existing system, the process is obviously a lot simpler. Either way, contacting a firm with the appropriate know-how can save you considerable time and potentially money.

What follows is a basic outline of the core elements needed for an umbilical system. There are, of course, alternative makes and models of equipment available and you can mix and match kit to produce your own bespoke system. Just ensure you check for compatibility.

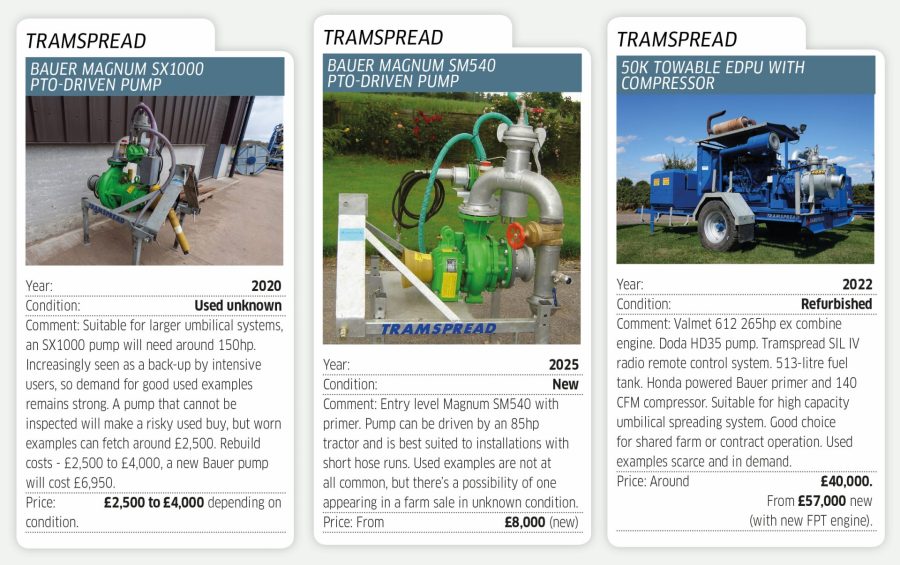

Pumps – pto-driven

A pto-driven pump is the simplest option, with used Tramspread pumps remaining similar to the company’s existing range. These can be specified with a Bauer or Doda chopping pump. The Bauer options consist of a Magnum SM540 or Magnum SX1000, the former having a lower capacity to suit smaller systems although, in practical terms, the Magnum SX1000 will be a more versatile buy as it will operate with longer umbilical hose runs.

Both incorporate a chopper on the suction side and should be able to handle solids such as straw, fibrous material, store crust or sludge at levels of up to 12%.

The larger pump system has a minimum power requirement of 150hp and would have been supplied with a hydraulic-driven primer as standard. SX1000 based Tramspread pumps will typically have a six-inch inlet and a four-inch outlet with gate valve and compressor coupling.

The Doda-based option has a slightly higher capacity but with that comes a greater power requirement, with 155hp at the very least advised.

The pumps are all mounted on a galvanised three-point linkage frame with a heavy-duty pto shaft. The smaller SM540 pump is the ideal choice for a transfer pump but it is also suited to running ‘smaller’ umbilical systems but will be a rare used find. With regards to performance, the Bauer SX1000 is able to:

- Handle up to 12% solids

- Pump up to 300m3/hour

- Manometric head* of up to 140m

- High cutting performance

*Manometric Head is the total pressure difference, or head, generated by a pump and is measured in meters of water column. A Manometric Head rating of 140m indicates the maximum height or pressure a pump can achieve when pumping water or other liquids. An SX1000 pump should, in simple terms, cope with significant gradients in the umbilical hose run.

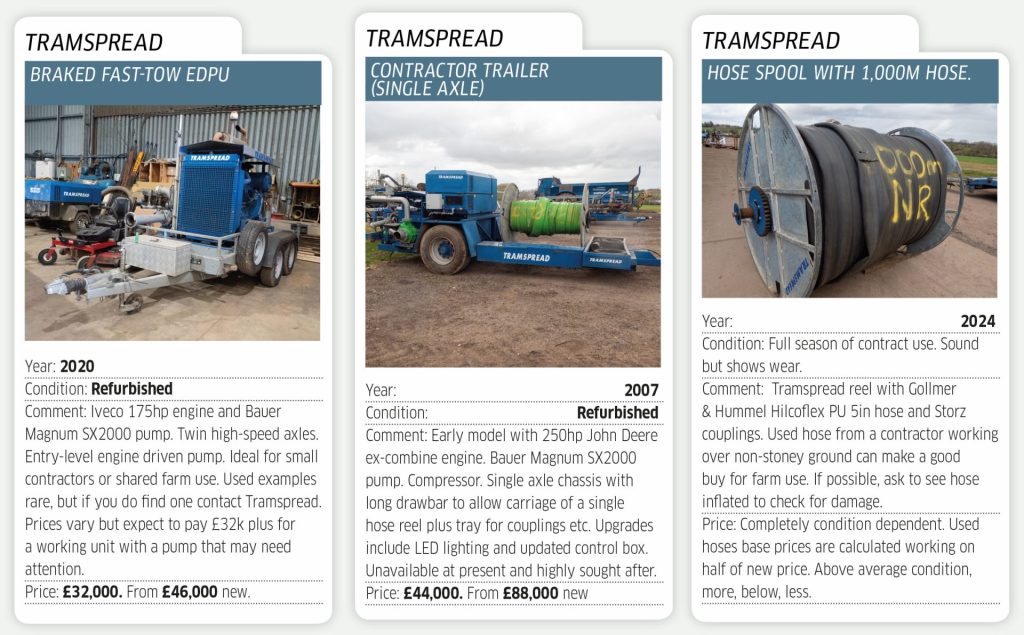

Engine driven pump units (EDPU)

Engine driven pumps have numerous worthwhile benefits over pto-driven pumps, including a significant saving in labour, machinery and depreciation, freeing up a tractor, as well as typically using 35% less fuel. Tramspread suggest an EDPU represents the most cost effective and environmentally friendly way of pumping slurry.

Tramspread purpose-built engine driven pump designs include skid-mounted, braked fast-tow, 50km/hr towable with and without compressor and specialist Contractor Trailer models (see separate panel).

Tramspread’s earlier pump units used re-conditioned combine engines as their power source. Most of these older designs remain in service both with customers and within the company’s own contracting fleet. Current pump units are powered by new six-cylinder FPT diesel engines, usually 175hp with 238hp as an option. All will be fitted with either the standard Bauer SX2000 slurry pump or optional Doda HD35. Both will come with a six-inch inlet and four-inch outlet.

All engine powered pumps are primed via a Honda-powered Bauer vacuum pump. Most EDPU pumps will have fuel tank capacity of around 500 litre with an automated SIL engine control panel and work lights.

Skid-mounted pumps will have fork tine and or three-point linkage systems to allow the unit to be moved into position. Trailer mounted 50km/hr EDPU are of the same spec as the skid versions, but mount on a braked and sprung axle chassis with wheels and tyres to suit 50 km/h transport speeds. Braked fast-tow units are mounted on a galvanised chassis with high-speed twin axles.

An engine driven Tramspread pump will be a rare used find. If you do come across one, contact the company for details and advice. Refurbished pumps are available.

What about a compressor?

Many Tramspread engine driven pumps will incorporate an air compressor as part of the unit, this having the power to blow the umbilical hose run through to clear it of slurry making it easier to roll it onto a reel when the spreading job is completed. The compressor units used are typically refurbished high output road units of 140, 180 or 260 CFM output. If you are building up an umbilical system using used elements from different sources, you may need to add a compressor to the list.

How a compressor is linked into the system may appear to be as simple as using a coupling kit and just hooking the pipe to the air supply, but it is a bit more complicated than this. Seek advice or you may end up getting covered in muck or filling the compressor filter with slurry.

Tramspread produces an optional sponge ball or ‘pig’ launcher which uses a pneumatic valve to isolate the launching chamber. This is to ensure it is kept clear of slurry. The ball is launched using the compressor’s full output to clear the hose. Worth consideration when looking at used pump units.

Pump control systems

The benefits of an engine driven pump can be taken a step further with a remote control and monitoring system. Tramspread offer two systems, GSM based Teletram 2020 and radio control SIL Vision. As each has evolved it is best to seek advice to ensure the system is viable and whether upgrades are recommended.

These systems enable the pump to be controlled from the applicator tractor, enabling one person to operate and monitor an entire umbilical system. When coupled to inlet and outlet pressure sensors and to a flow meter the system can also warn of potential problems to include drag hose leaks.

Both control systems can offer:

- Electronic throttle control

- Engine start/stop

- Fuel level sensing

- Pump operation control (and divert)

- Compressor start/stop

- Spread/divert hours recording

- Slurry spread volume recording

- Inlet and outlet pressure monitoring

- Automatic engine protection to detect low oil pressure, high coolant temperature and low coolant level

- Additional options include a nurse tank level sensor, cameras and pig (sponge ball) launcher control.

Hose reelers and spools

Tramspread mounted random wrap hose reelers can be used on the front or rear of tractors. They have increased in capacity over time to accommodate spools carrying from 600m to 1,000m of hose and more recently up to 1,400m. Tramspread galvanised spools are held in place by two securing pins to speed pick up and drop off. This enables a single reeler to be used to handle several spools.

As a used buyer, your choices are likely to be limited, but specifications to consider will include hose capacity in metres and if the reel spools are powered by twin or single hydraulic motors. A 600M model, capable of handling 600m of 4” and 5” diameter hose, uses a single hydraulic motor and gear to rotate the reel, the 1,000m version, which can accommodate 1,000m of 4” or 5” hose or 800m of 6”. will have twin hydraulic motor drive to increase hose recover power to deal with reeling in longer pipe runs. The recently released 1,400m model also uses twin motor drive, but used examples are unlikely to be available.

Trailed 1,600m and 2,000m reelers with segmented or random wrap are offered but have fallen out of favour, especially in the UK. Here the combination of a mounted reeler and multiple spools is typically much preferred. Used availability is likely to reflect this popularity.

Drag loop and hose humper

For spreading in tramlines (working parallel rather than corner to corner) a drag loop, or ‘cow horn’, can be connected into the pipe to manipulate the hose and move it across the field, with the cow horn tractor usually working at 90 degrees to the tramlines somewhere across the middle of the field to keep the hose moved over. Used drag loops are occasionally available, but they are not expensive to buy new.

The Tramspread Wagtail hose humper is another option, with pivoting and fixed versions offered, both using a rotating ‘wheel’ to move the hose over. It does not need to be plumbed into the system.

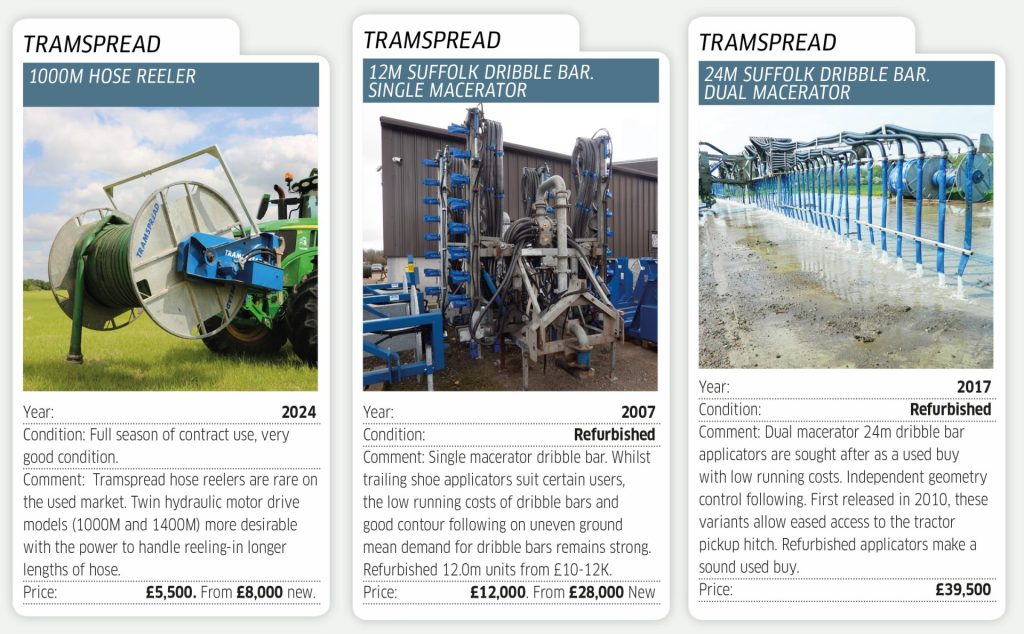

Dribble bars

Tramspread dribble bars may well be offered in a range of designs and, in the case of current units, with features that can include contour following and section control. When it comes to used finds though, you are going to again have limited choices. A 12m dribble bar with a single macerator will be among the more likely used offerings as these are increasingly traded in against either a wider or twin macerator alternative.

This is not to suggest that the wider units will never reach the used market. At the time of writing, Tramspread had a 2017 twin macerator 24m Suffolk dribble bar available. Recently refurbished, it was on offer for just under £40k. At the entry level end, a 12m Tramspread unit in good shape with a single macerator will sell from around £10-12k.

Most users will actually end up keeping an older dribble bar applicator as a back-up or to provide extra capacity. The galvanised construction and repairable design of the framework can mean these applicators can last for years, the macerators all being designed to be repairable or refurbished.

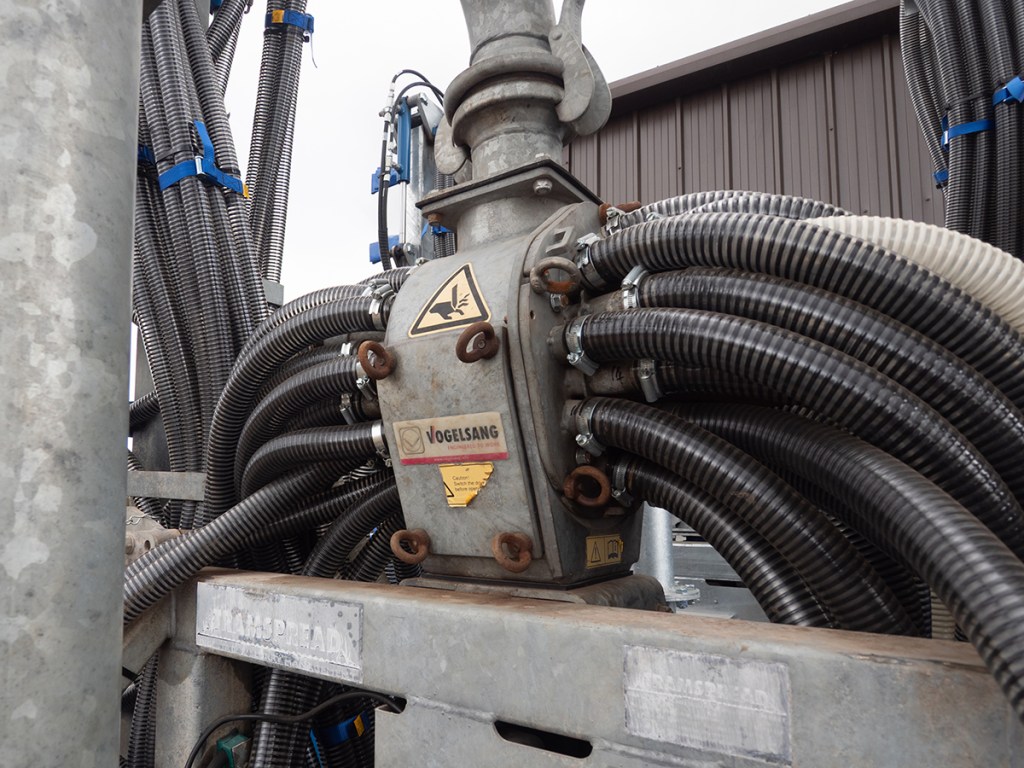

Single macerator Tramspread Suffolk dribble bars are offered in 6.0m, 7.0m, 7.5m, 8.0m, 9.0m and 12m working widths, these having a Vogelsang ECQ or an Alrena distributor/macerator. These are galvanised and can also be tanker mounted.

Built to essentially the same design, wider 12m, 15m, 16m and 18m twin Vogelsang ECQ or Alrena distributor/macerator versions are the next models up, with the option to incorporate valves to reduce the spread with.

If you need a bit more spreading versatility, Tramspread can sell you an 18m/24m dribble bar with aluminium booms with left and right geometric control and a parallelogram centre frame to allow spread height to be controlled independently of the tractor linkage and full electro-hydraulic control via an in-cab control box.

Precision farming

Tramspread began to offer a flowmeter, RDS rate monitor and in-cab printer to provide application records from 2008. Current systems now enable a flowmeter and NIR sensor to be connected to an in-cab monitor to analyse the slurry nutrient value. This data can then be set to automatically adjust the tractor’s forward speed to achieve the target application rate according to either NPK value or overall volume.

With a tractor connected to a John Deere Operations Centre system, information to include application maps can be transferred to the farm or contractor’s office. These elements may possibly be retrofitted to an existing dribble bar but check first. As the value of slurry and manure is increasingly recognised, accurate monitoring is yet more to think about.

Summary

Is this a complete and detailed look at the Tramspread offering? No, certainly not, there isn’t space to cover everything in detail let alone variations and one-off builds. But this is not the key point. If you are after a used Tramspread umbilical spreading system, or even individual components, your options may be rather limited and not reflect the broad offering of new units. You can, following the right advice, mix and match new and used kit, a point to consider if you want to set up an umbilical system from scratch.

With thanks to Terry Baker, Tramspread and Chris Lockwood

For more up-to-date farming news click here and subscribe now to profi and save.