By making its wider power harrow drill combination a semi-mounted unit, it’s not only easier to take on and off but also considerably reduces the amount of load on the tractor. We tested Pöttinger’s 5.0m wide Aerosem VT DD combi drill.

KEEPING IT BRIEF

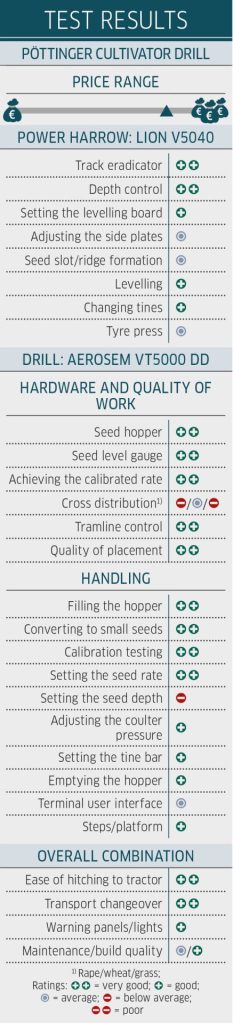

- The tested Smartline specification should be sufficient for most growers.

- Improvements could be made to the seed depth adjustment system and tyre packer at the rear of the drill.

- Manoeuvrability, calibration, distribution head, harrow depth adjustment and the split hopper result in a versatile drill without the need for any big changes.

Not only has Pöttinger got a beefy front tank/rear power harrow drill combi in its line-up, but it also has the Aerosem VT, a semi-mounted machine pitched at farms with medium to heavy soils. Subject of this month’s practical test is the 5.0m version, the VT5000 DD, which, along with the 6.0m combi model, was introduced in 2021.

5.0m and 6.0m machines

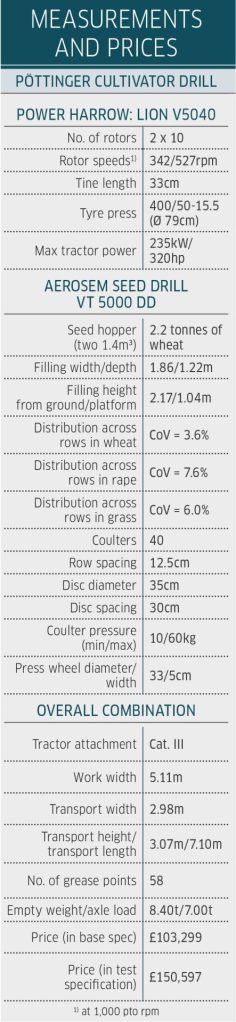

It’s not just the hopper capacity that differs on the two Aerosem VT DD drills (the 5.0m is 2,800 litres, the 6.0m having 4,600l), but also the power harrow. Our VT 5000 was paired up with a Lion 503C, rated for up to 320hp. This has since been superseded by the Lion V5040 — still with four rotors per metre, but this now has a two-speed gearbox that sees the rotors spin at 342 or 527rpm with a 1,000 speed pto. Another difference includes the modified side plates.

The 6.0m version (Lion V6030) also has a two-speed manual-shift gearbox for a rotor speed of 320 to 430rpm. Its 20 rotors can handle up to 500hp. Quick-release tines are an option on both of these machines.

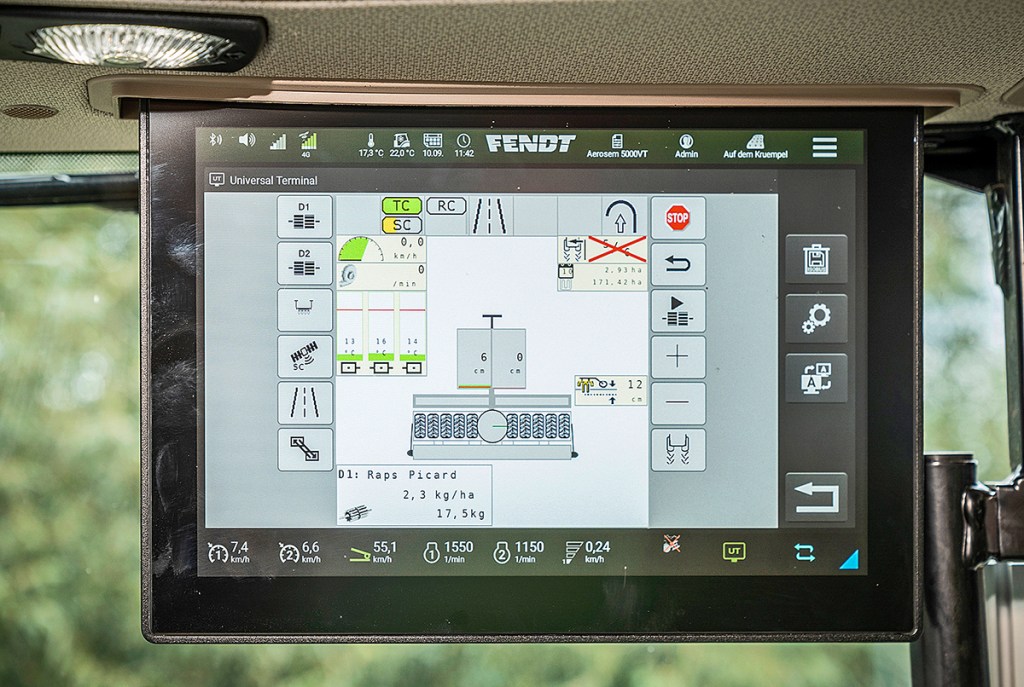

Back to our test machine. On the hydraulic side of things, our unit had the entry-level ‘Smartline’ system. This means that the individual functions are controlled from individual spool valves rather than from the terminal. For many, this approach will be perfectly adequate because most tractors will have the required three double-acting and one single-acting spool plus a free-flow return line.

Colour-coded grips on the hydraulic pipes make identifying which is which easy once you’ve realised the identifying decal is on the inside of the door for the drill’s storage compartment.

The alternative spec to the Smartline, is the Profiline, which sees all of the hydraulic functions operated by the load-sensing hydraulics.

Drawbar pivot point

No quibbles on coupling the Cat. III lower link crossbar, pto shaft, air brakes, ISObus and the power plug. One minor thing our test operators thought could be better was the retaining bolt on the parking stand — it’s a bit of a fiddle.

By moving the pivot point farther back on the drawbar (rather than at the crossbar), the VT is extremely manoeuvrable. Visibility down the slim flanks of the hopper is also excellent, which not only makes reversing with the drill very easy but also gives you an excellent view of the power harrow and coulters when in the field.

The VT is only available with a 50:50 split hopper. Of course, this means you can fill both compartments with the same variety of seed, in which case you will only have to calibrate one of the two metering units. Both units have corrosion-resistant components for handling fertiliser.

We liked the flexibility of the second hopper, whether for sowing a second variety, for fertiliser (it goes down the same spout as the seed) or for drilling at low rates.

Filling: Even if the lid is a bit stiff to open, the concept of it sliding down the right-hand side works well so you can load the hopper with nearly any type of loader. We were also impressed by the accessibility from the side platform — despite the high bottom steps — and the emptying of the pressurised tank. A connection for the airline would be the icing on the cake, as this would allow you to blow out the hopper when changing seeds. The screens inside the hoppers could do with being more easily removed, but then they are sturdy enough for storing small bags.

Two ultrasonic sensors, one in each hopper, get top marks as they indicate the amount in the tank to centimetre precision. Also, the metering units have low-level sensors, and as an extra-cost option the seed flow within the delivery tubes can be monitored, with their flow sensitivity varied on a scale from 1 to 10.

Calibration testing, too, was given a thumbs- up by our test team. Not only are the side-mounted metering units quick to access, but the tared calibration bags, external calibration buttons, hopper slides and the simple-to-open cell wheel cover all play their part to just make the rate checking job a more enjoyable task. Any niggles? Just that the design of the storage compartment for the metering accessories could be better laid out.

Power harrow with hydraulic damper

The power harrow positioned ahead of the tyre packer is also nice to use. It’s suspended from a parallel linkage and hydraulically damped. Depth of work can be adjusted with cm precision, with current depth displayed on the terminal — practical for changing conditions.

One minor drawback is that, when you make a big change to the harrow’s depth, you’ll need to manually reset the side deflector plates with the on-board tools. To adjust the two halves of the optional levelling board you need to hop out and again use the supplied tool. A laser-etched scale shows the depth — it works well. The space between the power harrow and the tyre packer has since been increased.

There were some issues with the trough seal during our season-long test, but Pöttinger quickly rectified this. Greasing up the cam clutch-protected drive shafts is a bit of a fiddle, especially with the hefty steel guards around the universal joints, because you can damage the speed sensors when refitting.

Last bit on the power harrow: it folds in two parts and is pressurised so that it can offer 5° of upward travel but no extra downward travel.

Then there is the pre-sowing consolidation, which is done with a pneumatic tyre press: each wheel is 400mm wide and 790mm high. Unlike other Pöttinger trailed drills, there is no contour following for the section, so it can’t adapt to the road camber which is no doubt going to cause inevitable damage.

The scrapers located in front of and behind the tyres worked without any issues in our stone-free conditions. Speaking to users, they have had issues with stones jamming in the scrapers on earlier drills, but Pottinger has replaced them with a modified linkage to remedy this.

Well bedded

The drill’s 350mm double-disc coulters are mounted on two beams, with equal length arms for the coulters. With a 30cm offset between front and back rows, the machine copes well with stickier soils and organic matter. We measured consistent pressures of up to 60kg on both the front and rear coulters. Overall, the 25mm offset-mounted discs worked without any issues on a variety of soil types, thanks in part to the internal scrapers.

A hole pattern between the coulter and the press wheel (330 x 50mm) is required for sowing different crops. To sow beans, for example, you need to refit one pin on each coulter. The middle position worked fine for us for sowing catch crops, rape and cereals.

Seed depth setting, though, does come in for criticism. To make a change you move a spring-loaded pin to a different hole, but there is a scale for reference. This is done four times, but to reach the middle two, you have to climb into/onto the machine.

Regarding coulter pressure, on the Smartline version, this is altered via a manual throttle next to the fan, as the oil is diverted through a bypass. By slightly adjusting the fan speed, the coulter press can be increased slightly. On the Profiline drills, the coulter pressure is altered from the control box/screen.

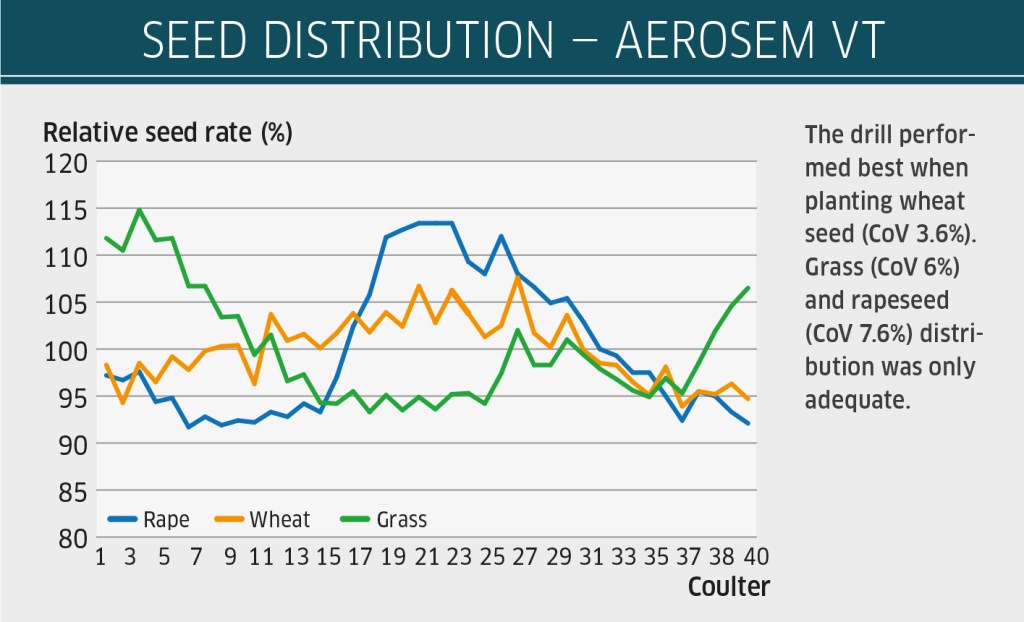

When it comes to all the cross-distribution measurements, the coefficient of variation in wheat of 3.6% was satisfactory but not so in grass (6%) and OSR (7.6%). These figures could be better.

The optional IDS distribution head offers lots of sowing possibilities. Equipped with one control flap for each row, you can switch sections up to 1.0m wide — also via GPS. It can also be used to drill various row and tramline systems. Unfortunately, a GPS-supported tramline system does not yet exist … for now.

Other details

- The power harrow and coulter bank are raised and lowered at different times.

- ISObus interface offers lots of functions — fine for regular users, but complicated for occasional operators.

- The combination weighs 8.4 tonnes, of which 7.0t is on the packer when empty.

- Field emergence was uniform and good.

- A front packer is available as an option.

- Depending on the topography and how much power harrowing you want to do, we recommend a tractor of 240 to 320hp.

- Almost 60 grease nipples, some of which are difficult to get at. That’s too many!

- The basic machine costs £103,299. Then add £19,404 for the seed bar, £5,348 for air brakes, £1,190 for the quick-change tines without wear pads, £1,467 for the levelling board and £4,205 for a set of bout markers. The seed flow monitoring costs £6,171, the IDS seed distribution head £7,803 and the following harrow £1,710. That’s £150,597 for the 5.0m we tested — and that’s without a terminal, spare metering rollers and eradicators.

Summary

It’s the compact and functional overall design of the machine that makes sowing with the Aerosem VT such a pleasure. Nevertheless, criticism goes to lateral seed distribution, the tyre packer when travelling on the road, too many grease points and the seed depth adjustment. Overall, though, we still liked the drill for the mentioned positives. We think the base “Smartline” version should be sufficient for most farms’ requirements.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.