Whether it’s replacing worn-out tyres or you’re wanting to fit a different size, there are several things to consider when booting up with different rubber.

KEEPING IT BRIEF

- Optimum lead is between 1.5-3.0%

- The calculation for determining lead is based on the tyre’s static rolling circumference.

- Inflation pressure and ballasting will also have an effect on the lead (dynamic rolling circumference).

Tyre specialist Herwig Kühne is a fountain of knowledge, because for around 50 years he has been been advising customers on suitable tyre combinations.

We also spoke to Stefan Rössler, of Michelin, who’s responsible for product and application technology for the firm’s agricultural tyres.

The challenge — getting the lead ratio

Perhaps the most important point about swapping or fitting new tyres is to ensure that the front wheels have the correct lead. Lead means that the front wheels cover the same distance slightly faster than the rear wheels when four-wheel drive is engaged. This configuration enhances the tractor’s drawbar power in the field and protects both the tyres and driveline.

Each tractor maker specifies the maximum lead amount as a percentage that relates to the number of rotations of the respective rear wheel. The permissible lead is normally between 0.0-5.0%. Some tractors will also specify a lower limit of 1.0%; for others the upper limit is 4.0%.

This information is particularly important for tyre dealers and suppliers. If the lead is too great or negative, various components will be exposed to strain and stress, especially on 40km/hr+ tractors where the four-wheel drive is engaged for braking. When you release the brake you will hear a banging noise. This increased strain affects the four-wheel clutch, the front axle differential, the axle bearings and the tyres themselves.

To eliminate this effect, experts recommend determining the lead with even greater accuracy and have an eye on the jobs the tractor typically carries out. Many years of experience show that a lead of between 1.5 and 3.0% is ideal for tractors that are used for both transport and field work.

This, however, is not always easy to achieve, because you need to find out a number of different parameters such as the rolling circumferences or the tractor’s transmission ratio (i-value).

Rolling circumference

If fitting new boots all-round, you can look up the static rolling circumferences in the tyre technical spec sheets. These figures specify the circumference under nominal load (maximum load to load index with specified air pressure).

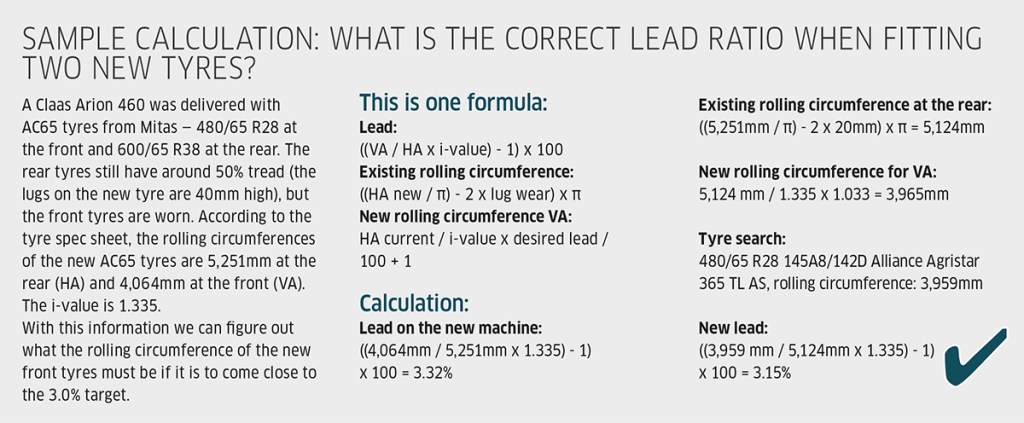

The actual issue is getting these figures, if only the front tyres are to be replaced, as the rear tyres are still in good condition. In this case, you’ll have to measure the tread depth on the rear tyres at three different positions (in the centre and on the outside) in the direction of travel. Next, compare the measurement with the tyre’s data sheet and calculate the difference. You will need to factor in wear; if the lug is 2cm lower than the lugs on a new tyre, for example. Our sample calculation shows one way of doing this. This requires the tyre’s actual rolling circumference for determining the suitable front or rear tyre.

The i-value — the transmission ratio

Another key parameter is the i-value — the transmission ratio between the rear axle and the front axle. Finding this value is not always easy because the gear pairings in the transmission may vary (even on what may appear to be the same model of tractor) or they may have completely different front axles.

Your tractor or tyre dealer should be able to help in determining this figure. This can usually be determined by the front axle or transmission serial plate. Wholesalers or manufacturers also have databases, such as Michelin with its Agro-Pro portal where you can see the figures.

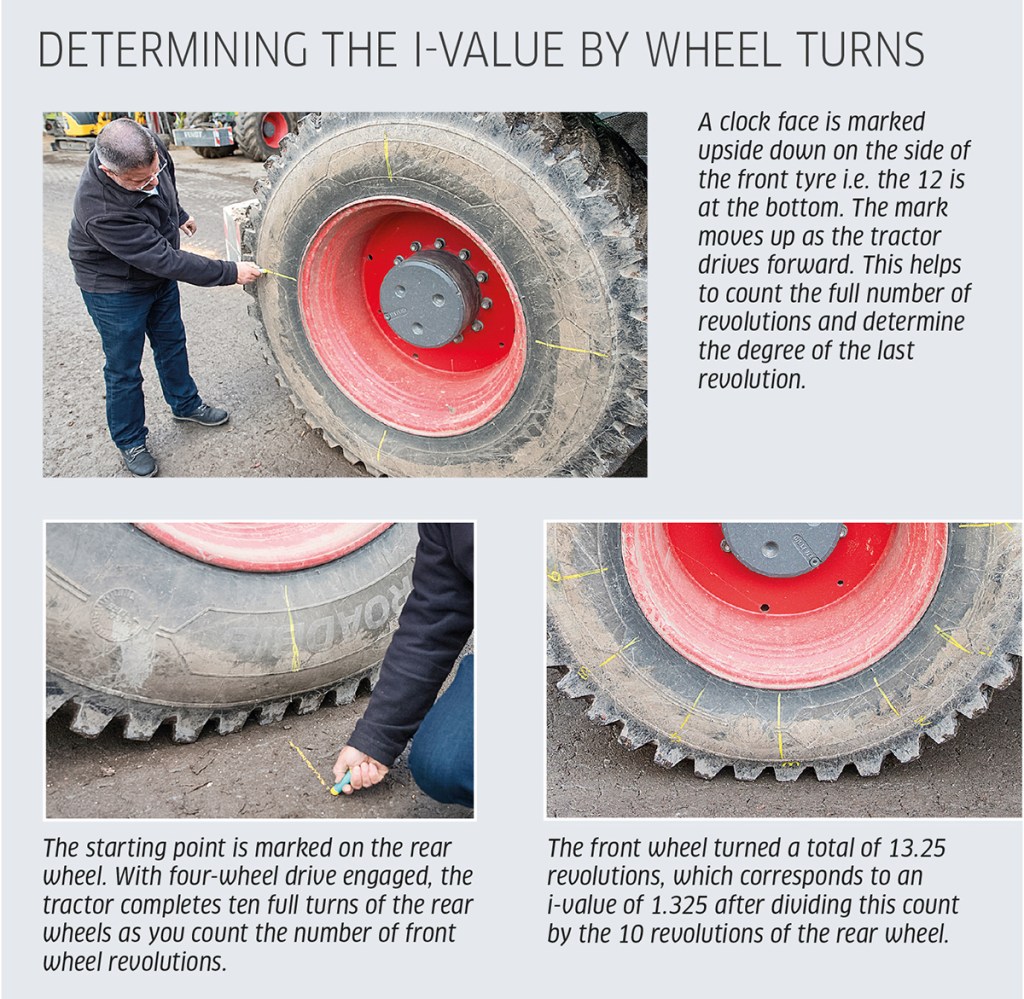

If you are still at a dead end, you can resort to doing a rolling test. This involves driving the unballasted tractor forward on a paved surface with the four-wheel drive engaged for exactly 10 revolutions of the back wheel. Make sure the tyres have identical pressure in them. As the tractor moves forward, count the number of revolutions of the front wheel.

Marking a clock face on one tyre, with 12 at the bottom helps. The front wheels usually turn 13 to 14 times while the rear wheels complete 10 turns. The i-figure is obtained by dividing the front wheel revolutions by the rear wheel revolutions. The lead ratio is obtained by repeating the test, this time with all-wheel drive disengaged. The difference between the two results is the lead.

This method can be problematic if the lead was incorrect in the first place, a symptom of which is that clunking noise as you release the brake with four-wheel drive engaged. In this case, you should jack up the tractor for doing the rolling test. Count the number of turns of both front wheels and then use both counts to calculate the average number of turns. This is due to the friction losses in the differential, especially if the driveshaft is not completely centred on the axle.

Doing the calculation

Once the all-important i-value and rolling circumferences of the rear tyres (HA) and front tyres (VA) have been determined, enter these figures in the following formula: ((VA / HA x i-value) – 1) x 100. This gives the theoretical lead of the tyre combination as a percentage. The next step is to determine the suitable tyre pairs. This often leads to using two different brands front and rear, especially when just the one pair is being replaced.

As a guideline for selecting the right tyre, you can calculate the lead of the existing pair when new, provided the tractor was delivered on them. Otherwise, it is advisable to aim for a lead of about 3.0% for new front tyres. This ensures an optimum range even during heavy braking (the dynamic rolling circumference) or as they continue to wear.

Inflation pressure

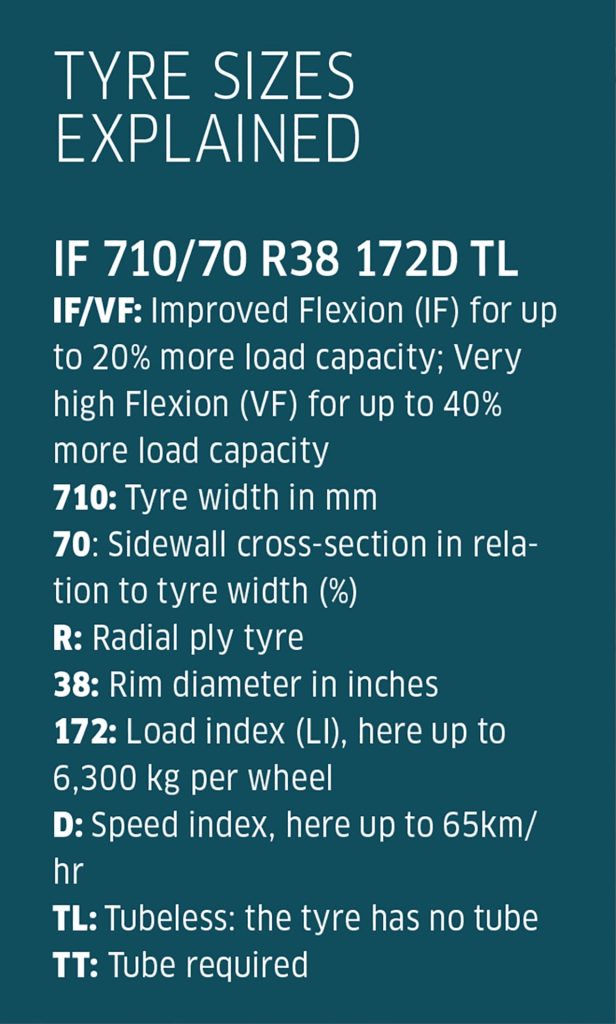

In addition to the rolling circumference as the most important criterion, you should also pay attention to a few other things. Particularly important is the load index (LI). This is provided in the tyre information (see box ‘Tyre sizes explained”) as a three-digit number, e.g. 178. It should correspond to at least half the permissible axle load of the tractor.

Furthermore, there are also IF and VF tyres. These meet special requirements, because standard tyres on high-hp tractors often reach their load limits when an implement is attached.

According to ETRTO requirements (European Tyre and Rim Technical Organisation), IF tyres must withstand up to 20% payload and VF tyres up to 40% — without altering the inflation pressure. The other way round, this means a VF tyre can be driven at up to 40% less pressure than a standard tyre although the payload has not changed.

NOTE: Permissible tyre pressures for the various axle loads always relate to work that doesn’t involve drawbar work and tractive forces. This means for drawbar work you should always inflate the tyres to the higher minimum pressure specified. It should also be noted that the rolling circumference decreases as tyre flex increases. This is the so-called dynamic rolling circumference, which is dependent on the payload and tyre pressure. Low tyre pressures at the rear, for example, can lead to increased lead, while low pressures at the front can lead to negative lead. This means that the flexing front and rear should be identical, and the air pressures should be adapted to the payload.

Observe tyre wear

You should keep an eye on the tread to determine any wear — not only on new tyres and when changing tyres. Uneven wear on the front wheels in particular is usually the result of inadequate track. To adjust the track, specialised companies such as Kühne utilise laser measuring systems that are attached to front wheel hubs. Pronounced wear on the outside of the tyres suggest toe-in. The opposite applies, if wear concentrates on the inside of the tyre.

Our expert has a simple tip on how you can visually check the tyre track configuration yourself. To do this, drive the machine onto a dry gravel surface or gravel road. Ensure that the front wheels are inflated well (at least to 1.7 bar) and check whether the dust collects in the centre of the lugs. If the dust deposits further inwards, this indicates toe-out.

One consequence of low tyre pressure is prematurely and costly damaged sidewalls. This problem is exacerbated if the tyres are mounted on rims that are too narrow and thereby constricted. The experts therefore always recommend choosing the widest possible rim for the tyre of choice.

Summary

Lead ratio is a particular issue for changing or fitting new tyres on tractors with 40km/hr plus speeds and all-wheel braking.

The experts recommend a lead of 1.5% to 3.0%, saying it is essential to determine it accurately. As inflation pressure and tyre flexing, too, influence the lead, it is very important to consider the lead when setting your tyre pressures.

Alexander Bertling

For more up-to-date farming news click here and subscribe now to profi and save.