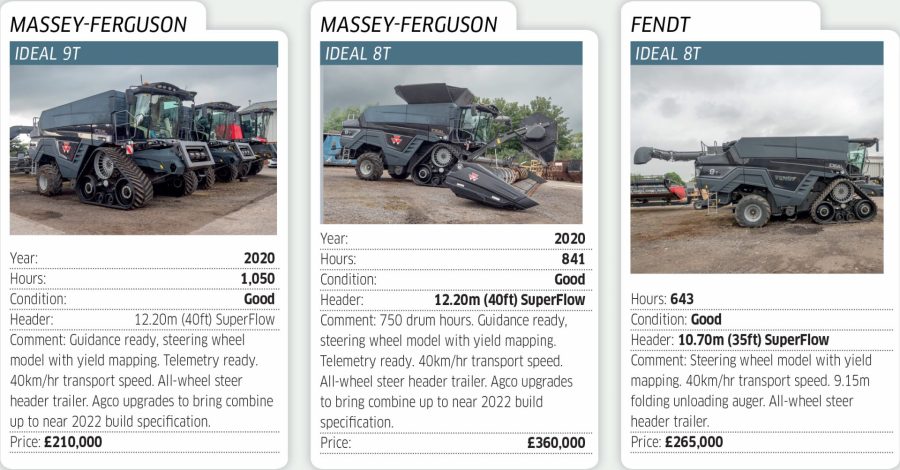

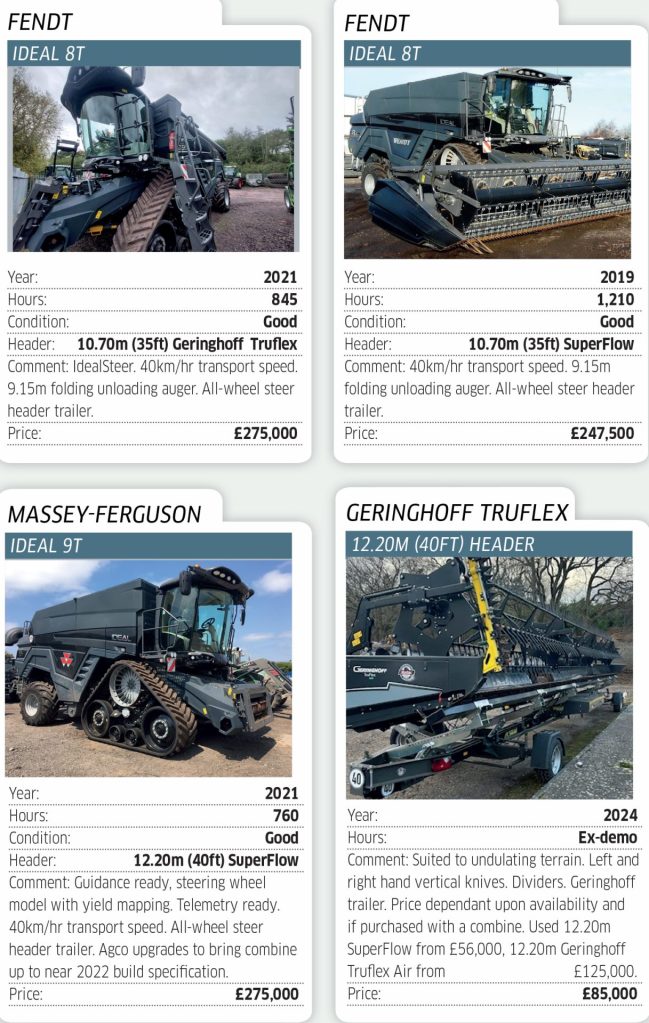

Agco’s Massey Ferguson and Fendt Ideal combines differ in two ways. Badges and Fendt having access to the highest capacity variant, the Ideal 10T. Everything else is the same including the black finish.

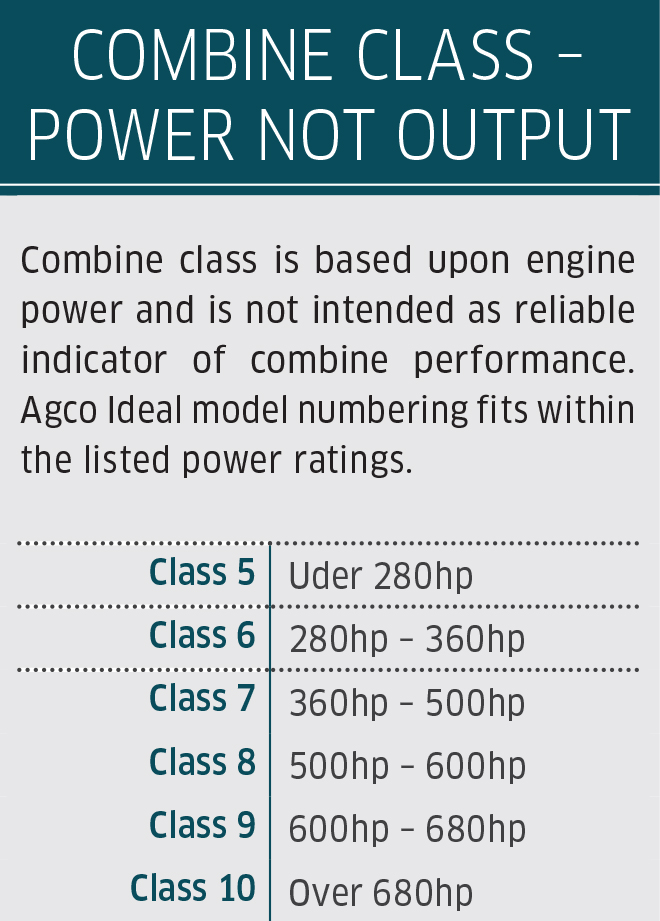

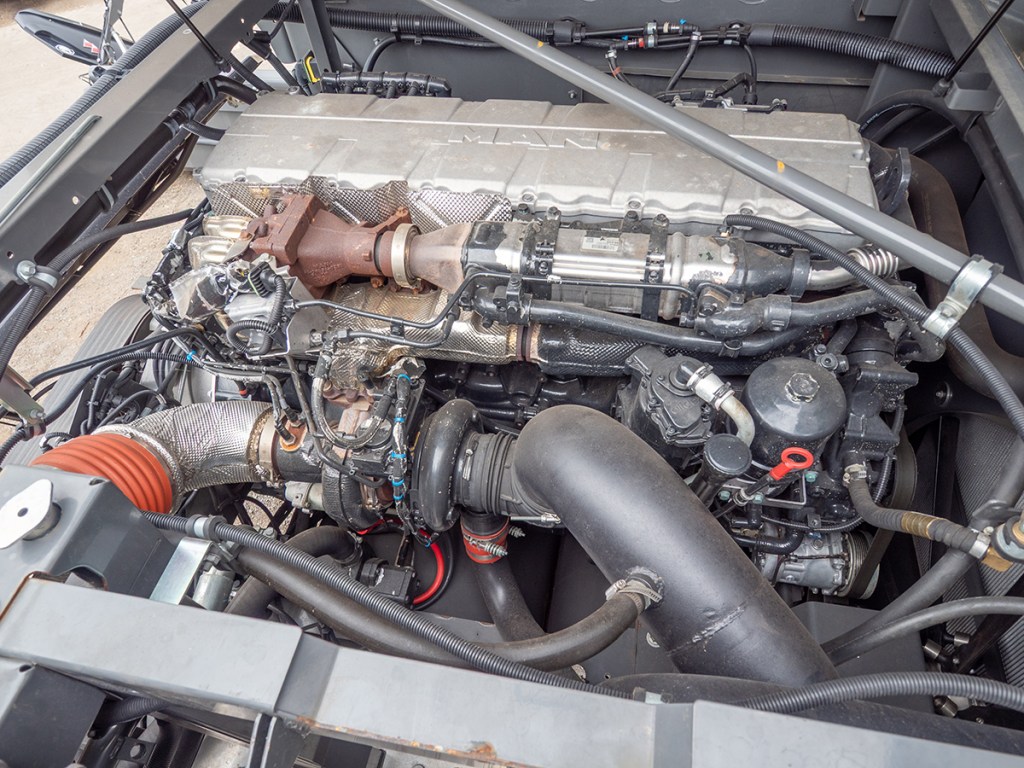

We took our first in-depth look at Agco Ideal combines back in November 2017, production Massey Ferguson and Fendt badged Ideal models reaching the UK in the 2019 model year. There are three Ideal combines available from Massey Ferguson, the single rotor Ideal 7 with a 451hp 9.8-litre Agco Power engine and the twin rotor Ideal 8 and Ideal 9 with 538hp 12.4-litre and 15.7-litre 647hp MAN power units respectively (at launch).

The Fendt range is the same except for the range topping 790hp 16.2-litre MAN engine Ideal 10T with TrackRide tracks as standard. Ideal rated power outputs have changed slightly over the past five years but the nominal outputs listed above remain a decent guide.

As a used combine buyer, it follows that you have the benefit of being able to find out how Ideal combines have performed in decidedly mixed harvests over the past six seasons. This will have provided a true insight into their harvesting performance. But here we just look at various checks and spec details. It is down to you to find out if a used Ideal is the right combine for your business.

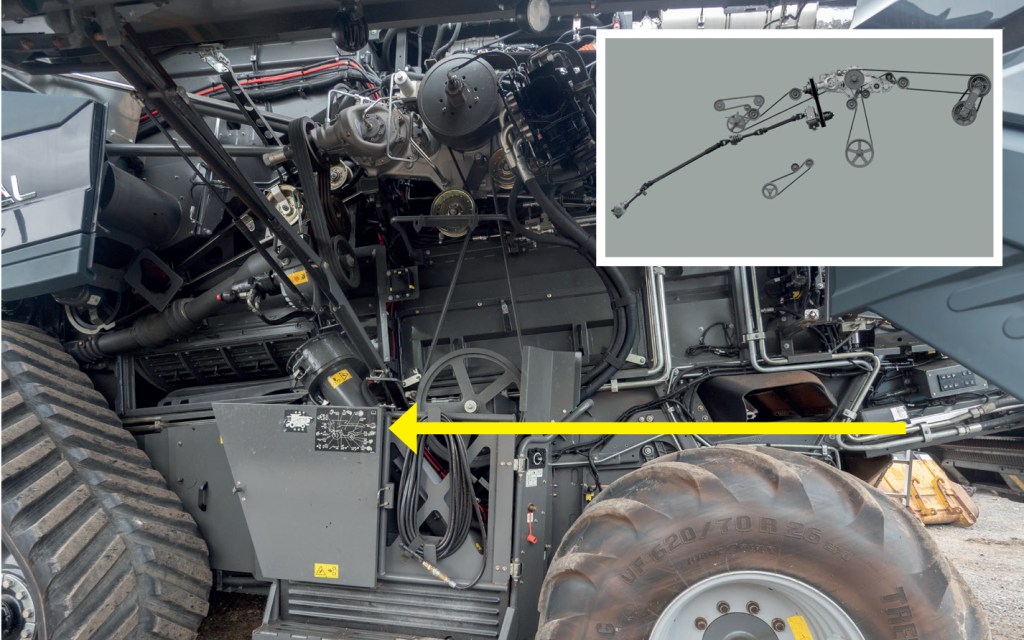

Fewer moving parts

Terms you will see repeated when describing the Ideal will include ‘simple’ and ‘straightforward’. Mechanically, Ideal combines are certainly far less complex than you might think but this is not the same as suggesting the fixable ‘metal bits’ are the only things to consider. You need to be aware that there are numerous sensors and automated features, and you should check the combine’s specs in detail. The likes of guidance and yield mapping were standard on UK machines, for example and the level of automatic crop settings offered.

As to mechanical checks, the same used combine buying advice applies. Start at the header and work back. As most Ideal models will be sold through a dealer it is fair to expect the machine to have been prepared for retail sale, with late autumn and early winter a great time to look for a used buy.

NOTE: New Ideal combines are offered with service and warranty packages of up to five years / 3,500 hours. A used buy may have the balance of its new warranty remaining but if this expires before you are going to work the machine ensure the combine has had a dealer check. This could ensure any necessary work covered by the warranty is completed ahead of it running out.

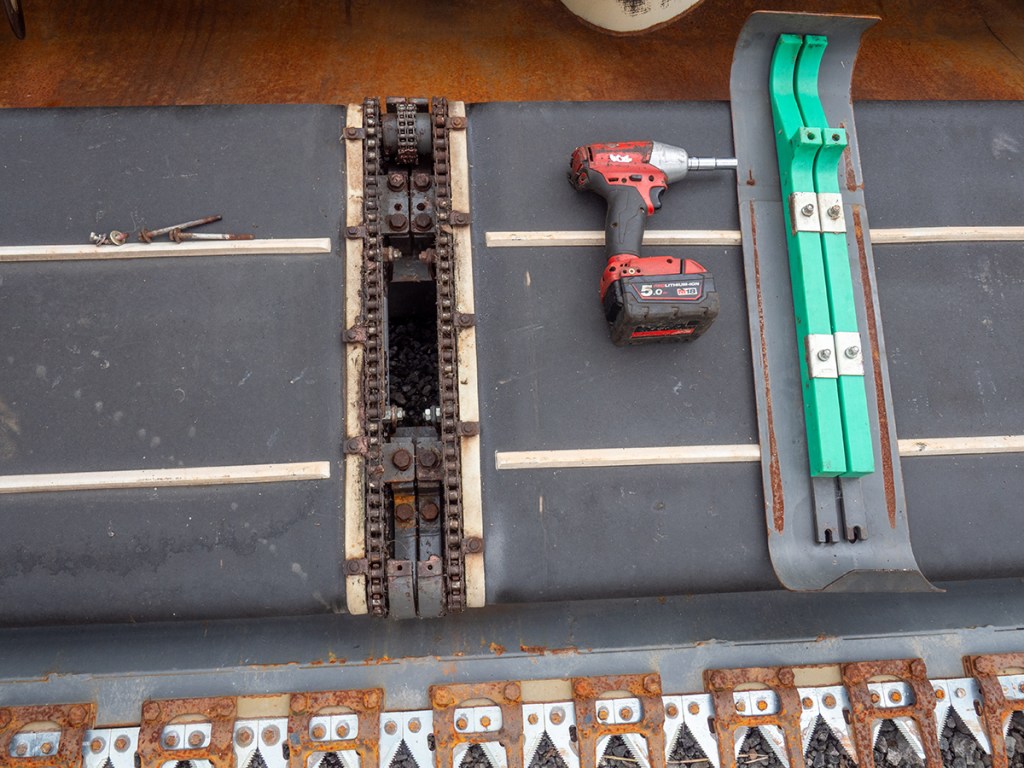

Headers/tables and intake

Massey Ferguson and Fendt Ideal models, like any combine, can be fitted with a variety of header designs. The standard offering will be a choice of 7.70m (25ft), 9.20m (30ft), 10.70m (35ft) or 12.20m (40ft) SuperFlow. These are fitted with three belts that run in the direction of travel to pass incoming crop to the cross auger. SuperFlow tables feature a 760mm diameter cross auger and a strengthened driveline when compared to the narrower PowerFlow headers offered on lower capacity Agco combines.

Geringhoff Truflex draper headers have been officially offered through Agco dealers since 2022, with around 30% of Ideal models in the UK now having them fitted from new. These headers also have belts but with these running across the table to feed crop to the centre of the header. Draper sizes on offer are 10.70m (35ft), 12.20m (40ft) or 13.70m (45ft) unit. A 15.22m (50ft) option for Fendt Ideal 10T models listed as a 2025 model year option.

Geringhoff tables are more complex and heavier than the SuperFlow but are designed to accommodate a degree of flex when working across undulating ground; Flex models have a rigid frame and flexible cutter bar, Truflex a flexible frame and Truflex Razor with both. In terms of performance in level going, a SuperFlow and Geringhoff should do much the same job. More recently the full range of MacDon headers have been made available, with some Agco dealers now authorised MacDon suppliers.

The combine feed elevator would have been a three-chain single slat design on the Ideal 7 and 8, this changing to the four-chain divided slat unit fitted to the larger combines from 2022. This change was made to reduce component differences as opposed to problems with the three-chain design, but a three-chain elevator upgrade is available.

A key difference between models is the lift capacity of the feed elevator lift rams, the Ideal 7 and 8 models having a 5,000kg capacity, the Ideal 9 and Fendt Ideal 10 both lifting 6,500kg to reflect their ability to operate with wider and heavier headers.

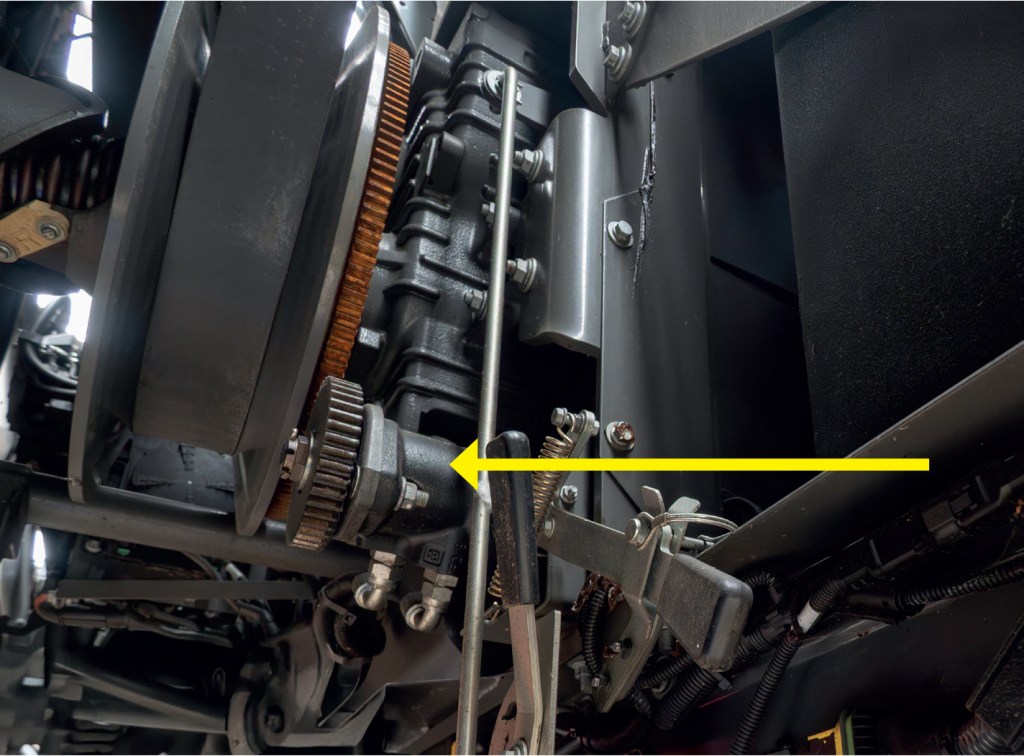

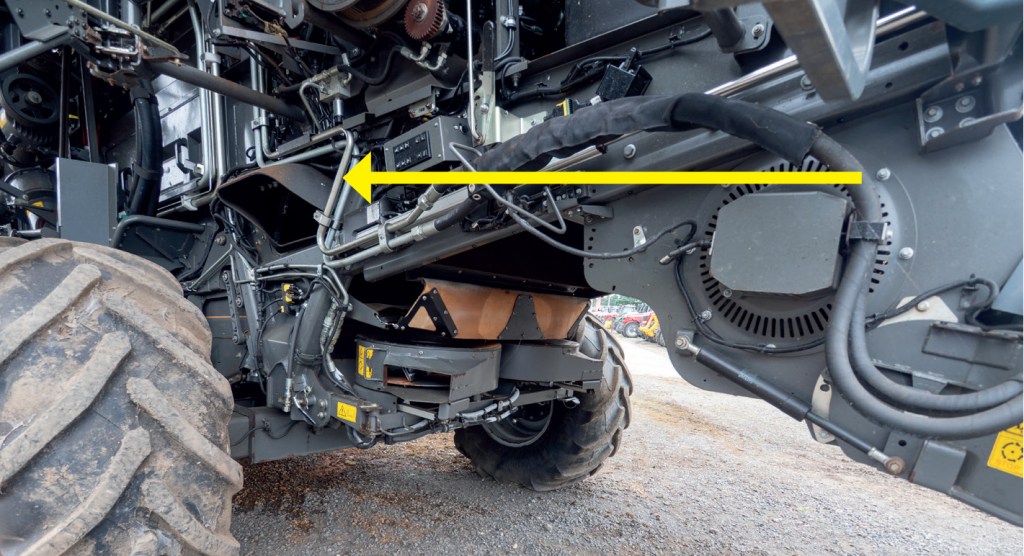

Drives and threshing system

From the header and elevator, the 600mm diameter 4.84m long rotors are the key moving part. According to Agco, the rotors consume 20-50% less power than some alternative designs. In our profi Practical Test of an Ideal 9T (05/22), we saw fuel usage of between 15-18l/ha.

The IdealBalance grain pans (Agco give most elements of the combine a name) are made from plastic. They mount on rubber bushes to allow shaking like a conventional combine grain pan with no provision for adjustment or calibration with fewer component parts as a result. A deep ‘belly’ at the front of the pan has the capacity to accommodate a large quantity of crop and is claimed to allow slope compensation of up to 15%.

The sieve area is 4.90m2 on the Ideal 8 and 9, increased to 5.40m2 on the Ideal 9 and Fendt Ideal 10. Total cleaning area to include the shoes is 7.45m2 and 7.95m2 respectively. Electric sieve adjustment is standard on all models.

Although an Ideal is mechanically simple, the electronics are far more complex, with 52 mass acoustic detection sensors and numerous cameras enabling the combine to self-adjust to suit conditions. An idea of how the sensors work includes those fitted to the rotors and the shaker shoe. Between them, these sensors measure crop flow and combine data from a grain quality camera to monitor grain losses, with the percentage of cracked grain shown in real time on the in-cab display.

This information can enable the combine operator to adjust the ratio of output to grain quality, the combine automatically fine-tuning the rotor, fan speed and sieve openings. It is all clever stuff. As a used buy, you will of course need to know if these elements of the combine a reliable. Asking around, it would appear some users have had problems with their Ideal combines but these automated systems tend not to be among them

Residue management

The straw chopper has hydraulic drive, with deflector vanes to vary the spread pattern, with manual or electric adjustment. Agco offered ActiveSpread oscillating straw spreaders as an option, with the latter becoming a default fit from 2023. The vane spreader system works fine on headers of up to 10.70m but could produce a less even spread pattern when dealing with the wider headers typically fitted to the Ideal 9 and Fendt Ideal 10.

On pre-2023 models, the void ahead of the chopper can suffer residue build up, an easily spotted filler plate added to later combines solving the problem. It follows you get what is fitted to a used buy.

There are a pair of hydraulically powered chaff spreaders that adjust to blow material outward or into the straw swath. These units are pivot mounted to allow them to fold out of the way to access the sieves.

Grain tank and unloading auger

Wheels and tracks

Most Ideal 8 and 9 will be 8T and 9T variants fitted with the TrackRide tracks. When considering a used model, do not overlook the transport width of the combine, variants running 800 and 900 tyres being wider than even the widest track alternative. Unless a machine has done a lot of road travel, the tracks should last for near the life of the combine, the same applying to tyres. Driven rear wheels are an option on all models, with a retrofit possible. Not over common in the UK.

There are no specific problem areas with the tracks, so just look for wear and damage to the drive, idler and intermediate roller rubber. Bearing wear should not be a problem, but some may overlook routine greasing. As the tracks automatically tension, any sag suggests there is a problem with the tension system but this is unusual.

Cab

Apart from the in-cab cool box changing to a true fridge from 2024, little will have changed in terms of overall Ideal cab specifications, with a key used check of selecting between conventional steering wheel or IdealDrive joystick steering on TrackRide T models. IdealDrive does away with the steering column, the joystick mounting on the left seat arm rest.

In profi tests, in-cab noise levels of up to 77d(B)A were recorded.

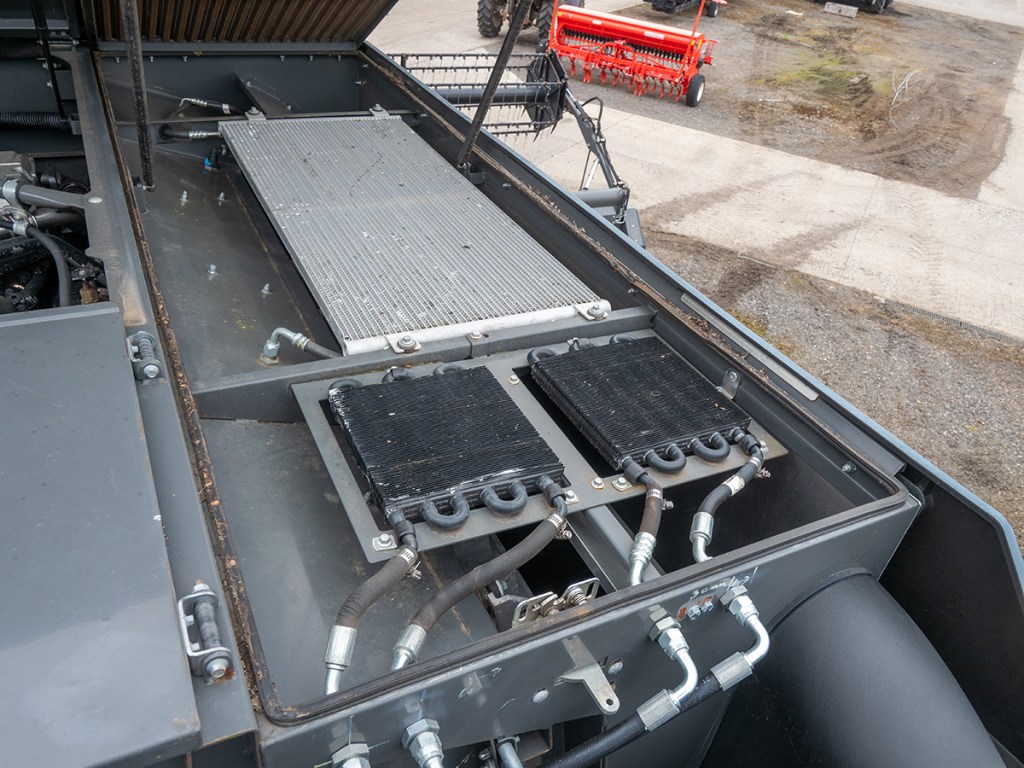

Engine and cooling

Early Ideal models could have problems with the AdBlue system related to blocked breather filters. AGCO resolved these and other details with several upgrades so this should not be a worry for used buyers. There were also a few changes made to the heat shield on some machines but overall engine and cooling pack related trouble spots should not be a concern.

NOTE: Ideal service intervals are 250 hours minor and 500 hours major.

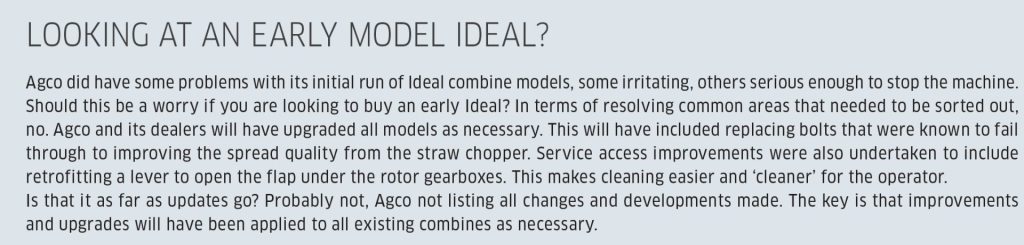

Summary: The oldest Ideal combines will have six harvests behind them, with AGCO clearly keen to ensure these combines have delivered in terms of both performance and dependability. As a used buyer, a key point to note is that early model problems were noted and the first machines sold will have had upgrades that should ensure any teething problems are now just that.

Can you therefore drop your used buying guard? No, of course not. Wear and tear plus less than diligent maintenance can see even the best of machines suffer. The key is to look for a used buy well ahead of needing it, doing your specification homework and buying the best combine you can afford. That should lead to an Ideal buy.

IDEAL FROM A DEALER’S PERSPECTIVE?

Keith Davies has been involved with Massey Ferguson combines for over 35 years and retains a soft spot for hybrid Massey Ferguson 9795 Delta models but sees the Ideal as a major advance.

“Delta combines are underrated in my opinion. They are extremely versatile and dependable if properly maintained” he says. “As the Ideal range was completely new, I thought it would take us time to learn what these models could do but as it turned out they are probably the simplest combine to set up I have ever worked with. The automatic pre-set crop settings are easily tweaked to suit varying conditions, the high discharge rate of the unloading auger proving the only thing that caught me out. Some early Ideal models did have a few problems but these were ironed out with the benefit of factory updates. This can make even the earliest of Ideal combines a safe and dependable used buy”.

Chandler’s combine service specialist Simon Osborne says an Ideal combine is not difficult to maintain.

“These are mechanically straightforward combines”, points out Simon. “Most maintenance tasks can be carried out in a farm workshop and I can typically resolve any running problems users come up against over the phone. It is clear to see that a lot of thought has gone into making the combine easy to look after. Once you know your way around the combine it is a very simple machine”.

Rob Immink says used Ideal combines are currently competitively priced due more to the current combine market overall as opposed to problems with the combines themselves.

“Agco were quick to get on top of teething problems with early Ideal combines, all 2019 and interim model year models having been brought up to essentially the same build as 2022 combines,” explains Rob. “The Massey Ferguson PSB programme was comprehensive, which helps us ensure buyers of a used model will not run into any of the known teething problems we first ran up against. As a dealer, this helps us sell on a used buy with a high level of confidence that it will not let a customer down”.

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.