If you have a preference for straw walkers, then keep reading as we round up the best selling five- and six-walker combines currently sold in the UK and Ireland.

The straw walker combine has been the mainstay of the cereal harvest since the 19th century, but in recent years rotary separation technology has offered performance advantages which have seen wide adoption of this type of machine on farms requiring higher outputs.

Such has been the impact of this trend that up to 78% of combine harvesters sold in the UK in 2025 were rotaries or hybrids, compared with 71% in 2024 and 60-65% in the previous five seasons, says New Holland product specialist Nigel Honeyman.

“Ireland is going the same way, but it’s currently about where the UK was 15 years ago with still a good number of straw walker machines sold,” he comments.

Nigel adds that walker combines have traditionally been easier machines to operate and maintain.

“Although that’s changing – our new CR 11 rotary has been designed to be simpler and more user-friendly. But the straw walker system is well-established and understood technology; it is maintenance-intensive but straightforward.”

He says that the walkers themselves are the ultimate limitations on output in ‘normal’ UK harvests. “The grain is often ready when the straw is still green, so the losses limit performance. Centrifugal separation on a rotary overcomes this.”

However, Nigel points out that New Holland developed variable speed walkers to improve performance. “The operator can slow the walkers down to keep straw on top of them as long as possible, which works well to a certain capacity limit.”

Not left behind

Technology developments are still being made to walker machines. Nigel Honeyman points to the option of NIR/infra red sensing on the New Holland CX range, allowing straw walker machine purchasers to carry out detailed crop analysis.

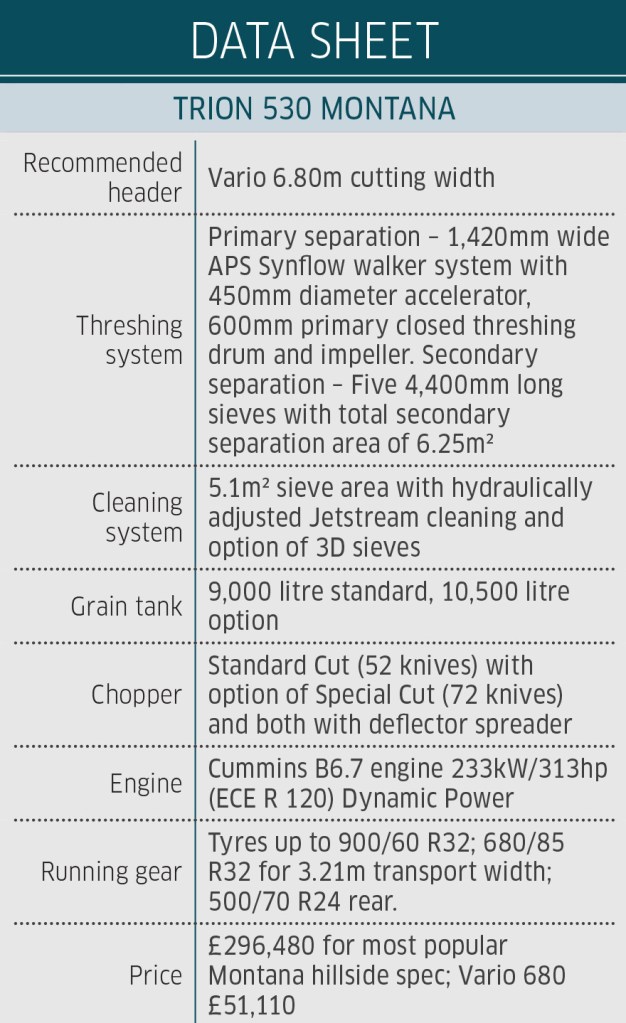

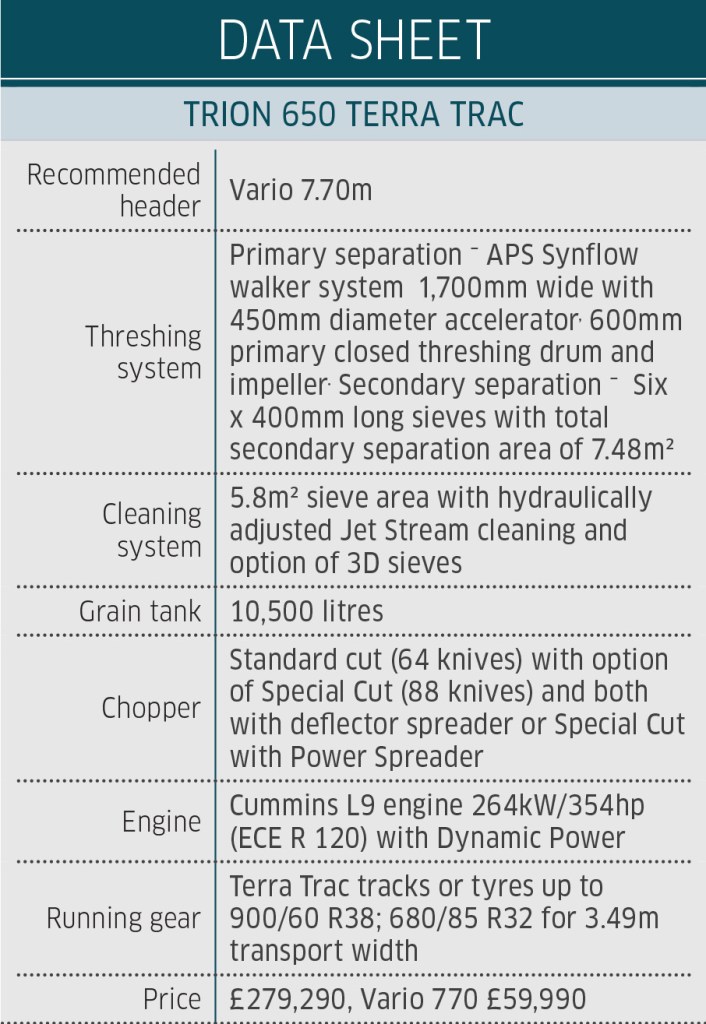

Claas has also focused on technology, adding CEMOS, full automation of harvest settings to Lexion walker machines in 2020 and introducing it on its latest Trion series in 2021. Product specialist, Rob Portman comments that by controlling drum speeds and concaves, CEMOS can increase outputs on a walker Trion.

The five- and six-walker Trion is equipped with the latest cabs and drivelines in line with Lexion developments.

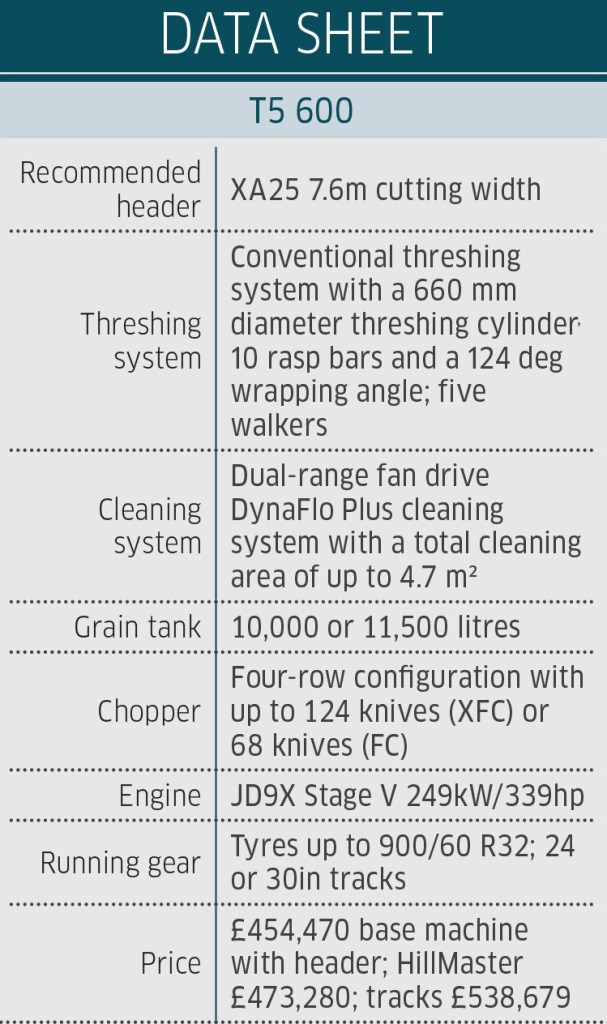

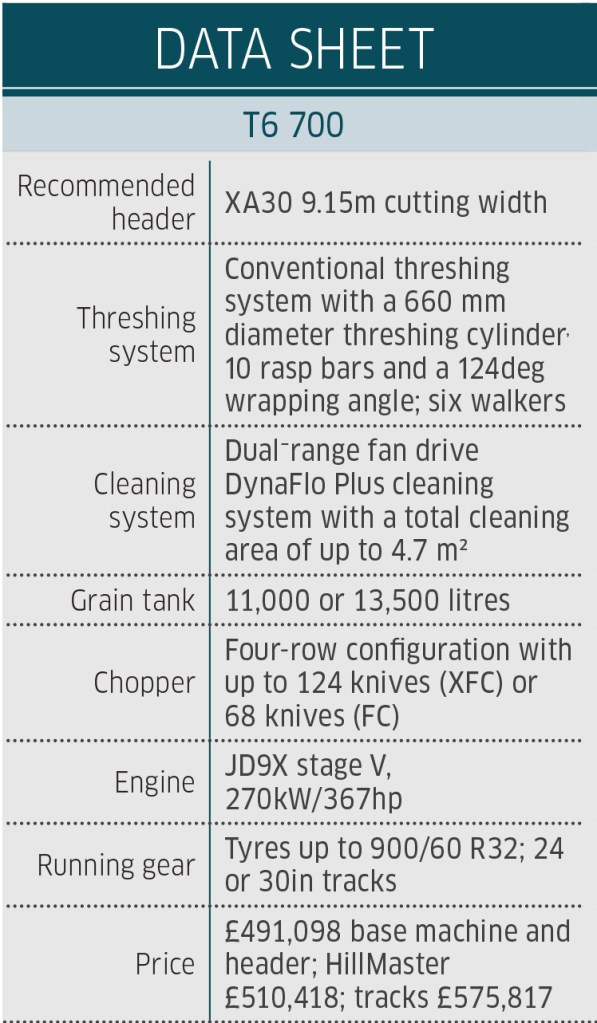

John Deere may be bucking the trend in this sector, suggests marketing manager Chris Wiltshire. “This segment would be under pressure due to the general market conditions. However, I would say that larger walker combines and in particular our T6 range are still very well accepted. The capacity of this size of combine does equal if not exceed some of the smaller rotary combines with the added benefit of much improved straw quality.”

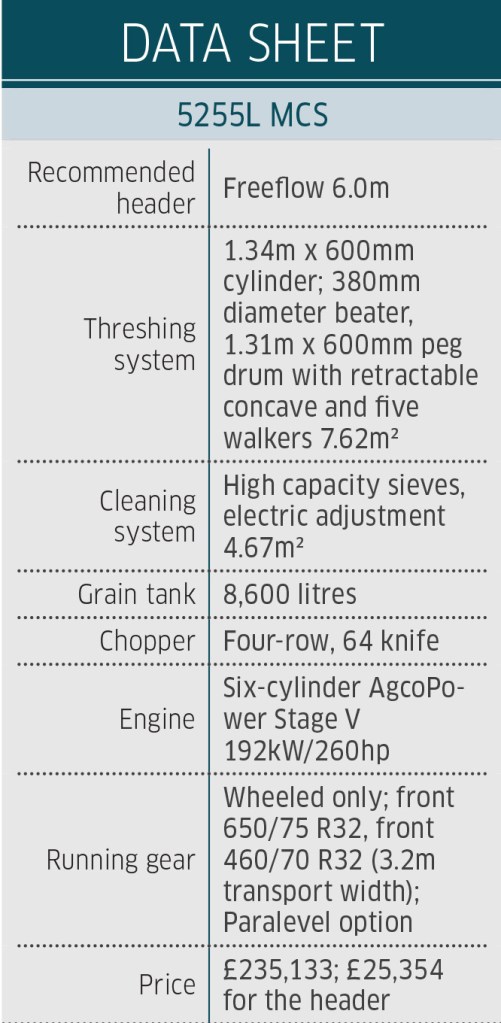

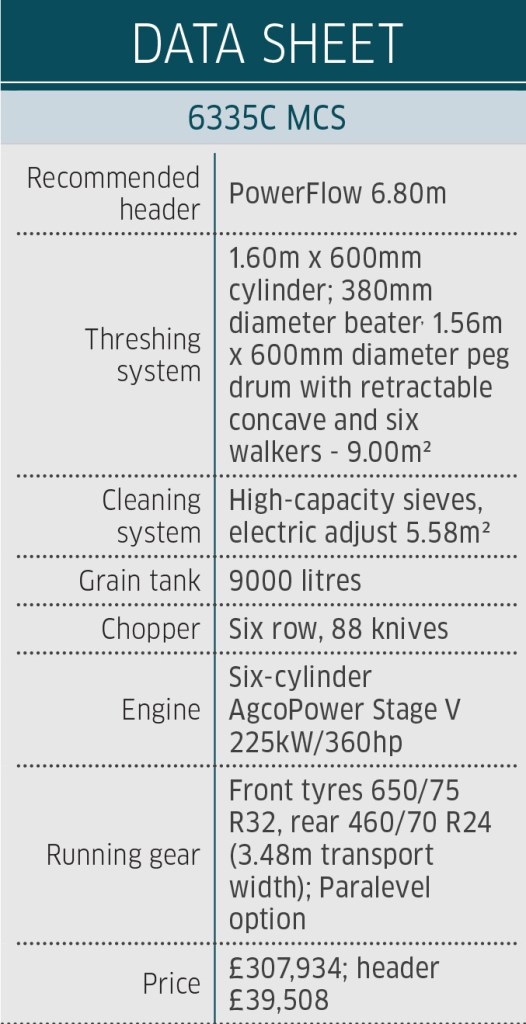

Fendt product specialist, Ant Risdon comments that the brand tends to be associated with larger farms, so sees fewer sales of small combines but a walker machine would still be an option for some customers. The smallest Corus 500 range remains in demand, including the first new combine sale to Jersey in recent years. In the middle of Fendt’s range is the L series, with a more basic spec than the C series which offers telemetry and other technology.

“A five-walker C series would appeal to a farm with 210-375ha, offering familiar tech and dealer back-up for these customers,” explains Ant. “Paralevel chassis levelling is a popular feature for customers on steeper land.

“However, at the top end of the six walker C series, a customer who sees his acreage increasing from 400-600ha acres may prefer the Ideal 7 rotary. It gives the extra output and is very reliable.”

He adds that while straw quality was always a big draw for walker combines, the Ideal was designed with this in mind.

Claas also sees a big shift toward rotaries, but the firm’s Rob Portman says that the five-walker machines are still popular on mixed farms with smaller acreages and a requirement for straw.

“But customers are increasingly considering whether a single rotor APS Trion could be the machine for them, especially where they are taking on more land or experiencing shorter weather windows – they will get 25% more output with a hybrid machine.”

He adds that a Trion hybrid would be competitive on price with a Lexion six-walker machine.

Montana hillside specification remains popular in areas such as Devon and Cornwall.

At the entry level, Claas introduced the five walker Evion for farms around 400 acres, sold in small numbers in the UK.

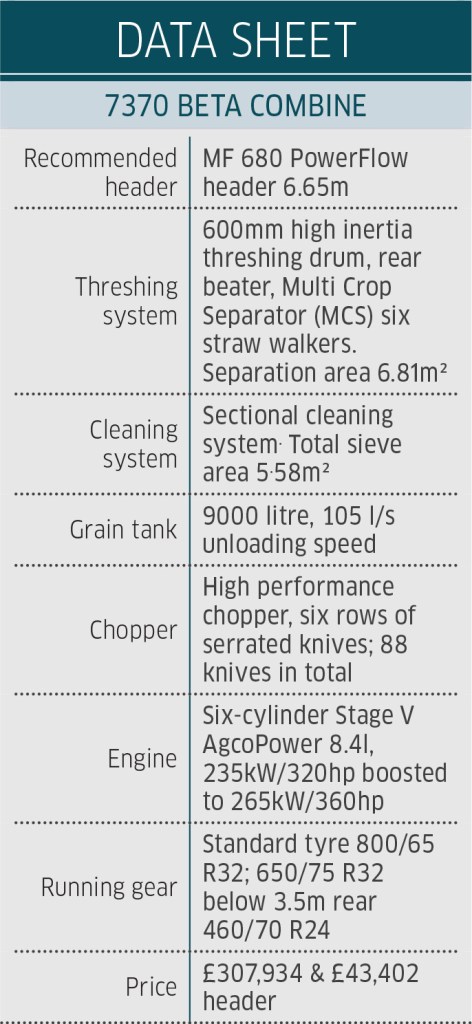

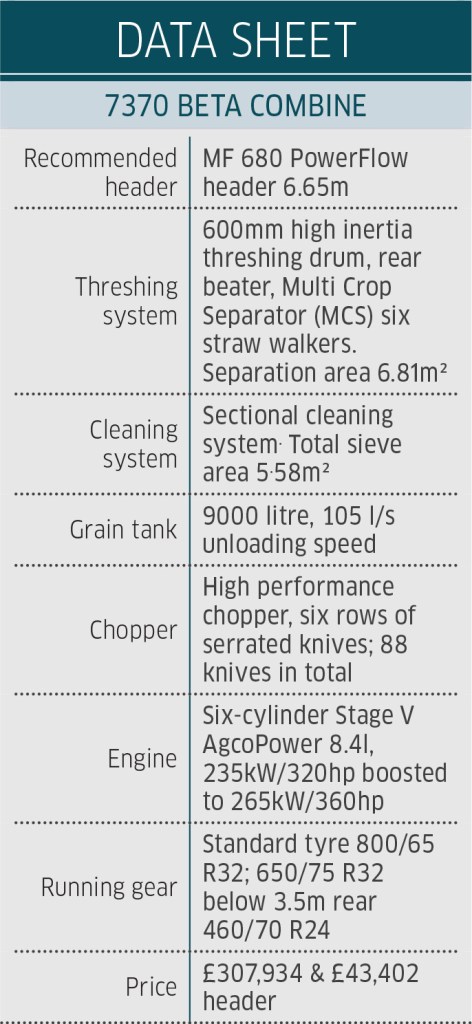

Reliability and long service life remain selling points for Massey Ferguson walker machines, comments product specialist Howard Warnes. “An economical price for a good basic machine is the usual requirement, for family farms who are already MF customers.”

Second hand markets

Manufacturers point to ongoing demand for used straw walker machines in the UK. Nigel Honeyman comments that UK machines are also popular in France; as there is little maize harvesting done with combines in the UK, the relatively low wear makes these a better bet than a machine sourced from the French market.

“The narrow lanes and gateways in south west England and in Scotland mean that there is always a market for the five-walker machines.”

Rob Portman comments that Claas walker machines tend to stay in the UK, and remain popular in Ireland, although there too, he reports a move to small hybrids.“It’s the larger hybrids and rotaries that go out of the country.”

Howard Warnes points out that Massey Ferguson combines are often sold within the local area, where purchasers know they have been looked after by a familiar dealer, adding a premium which helps the seller meet the cost of his new machine.

BUYERS GUIDE

CLAAS

A new model was added to the five-walker range in 2023, taking the power band up to 540hp. Updates for 2026 include the availability of Apple Car Play and Android Auto Radio in the cab, a compressed air connection with a blow gun for quick and easy cleaning of controls and the cab floor, new interior lighting, and additional storage provision. LED all-round and rear lamps can be specified.

JOHN DEERE

Walker combines were updated with new T5 and T6 models in 2024, featuring the same cab as on the flagship X9 harvesters plus a range of automation tech designed to increase productivity. This includes the large screen G5 Plus CommandCenter display with JDLink connectivity offering AutoPath, Machine Sync and Harvest Lab grain sensing monitoring.

The JD9X engine offers intelligent engine speed management which improves fuel efficiency by reducing engine rpm during road transport.

Grain tank capacity has been increased by 15% for the T5 to 11,500 litres for T5 and 23% for the T6 to 13,500 litres, with the option of an adjustable spout and unloading up to 150 l/sec.

FENDT

Three ranges of walker combine: the Corus 500, L series and C Series

MASSEY FERGSUON

Three ranges of walker combine: The Activa, Activa S and Beta

NEW HOLLAND

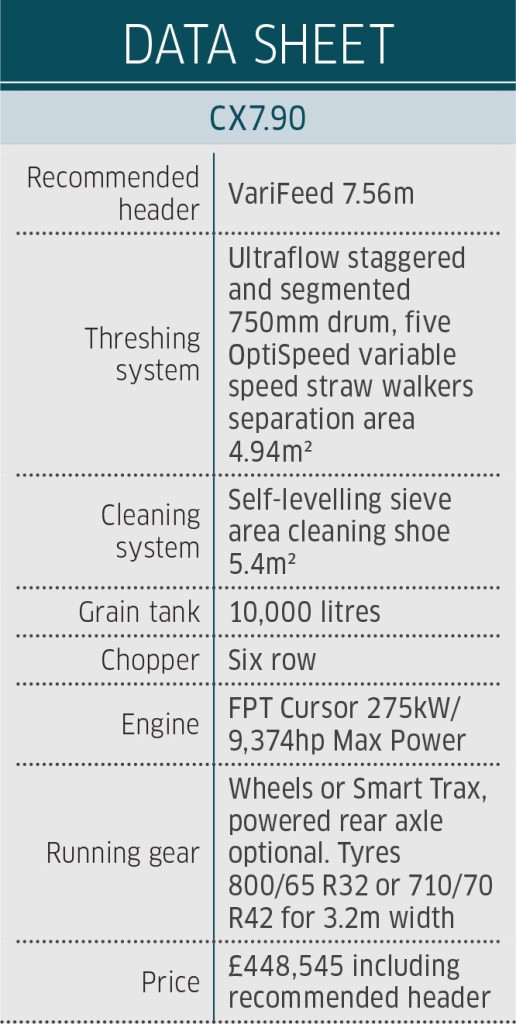

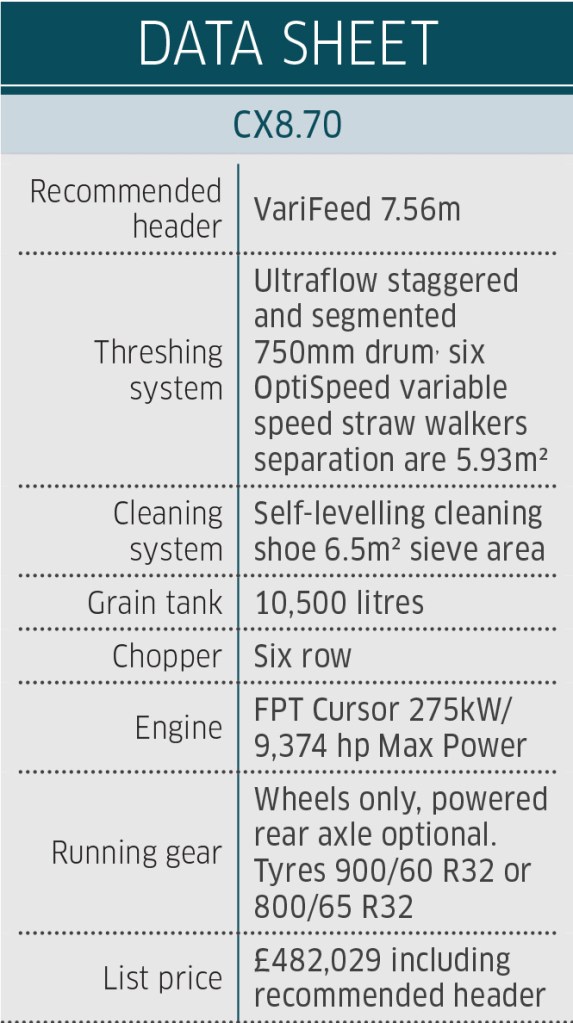

Latest developments to the CX 7 and 8 flagship machines include improvements to the cab to bring them into line with the CR series. This includes larger Intelliview screens with more processing power and integrated with telematics and New Hollands’s Field Ops platform, making it easier to send data to the farm office.

The Ultra Flow Drum is now available on all walker combines. This uses shorter, staggered rasp bars at the front edge of the concave, designed to feed more steadily and smoothly. This is said to improve performance in damper conditions and green straw, reducing noise.

Multi-drum design uses four drums in a line to improve threshing while maintaining straw and grain quality.

For more up-to-date farming news click here and subscribe now to profi and save.