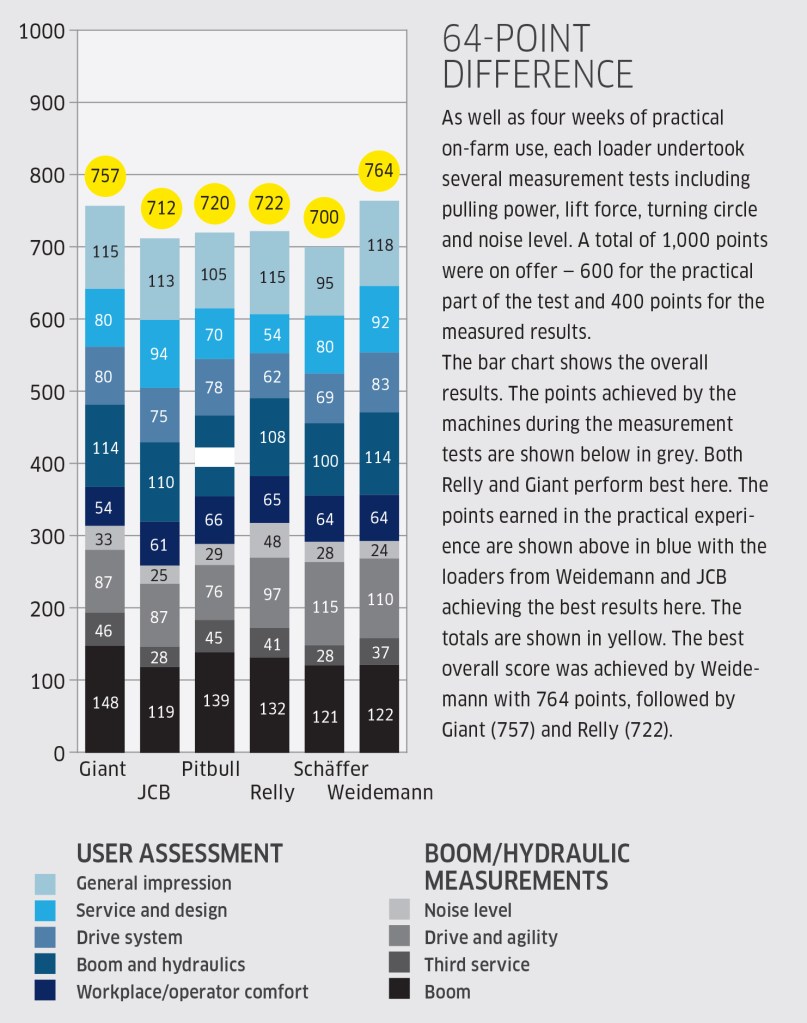

The market for battery-powered yard loaders in the 2.5t class is still relatively small, but, if you are operating in and around buildings and have on-farm electricity generation, then they could appeal. Four farm machinery magazines from Northern Europe have put these six machines to the test.

KEEPING IT BRIEF

- Six electric-powered yard loaders were compared in the Netherlands.

- Differences mainly relate to operating comfort, cycle times and forward speed.

- While they are much quieter than their diesel-fuelled counterparts, they are no faster.

While there are over 30 different makes of diesel-powered yard loaders, only around six of the main players offer an electric version. These six manufacturers took part in this comparison test, though the 2,325kg Schäffer 23e was almost too light compared to others in the group. This is our list:

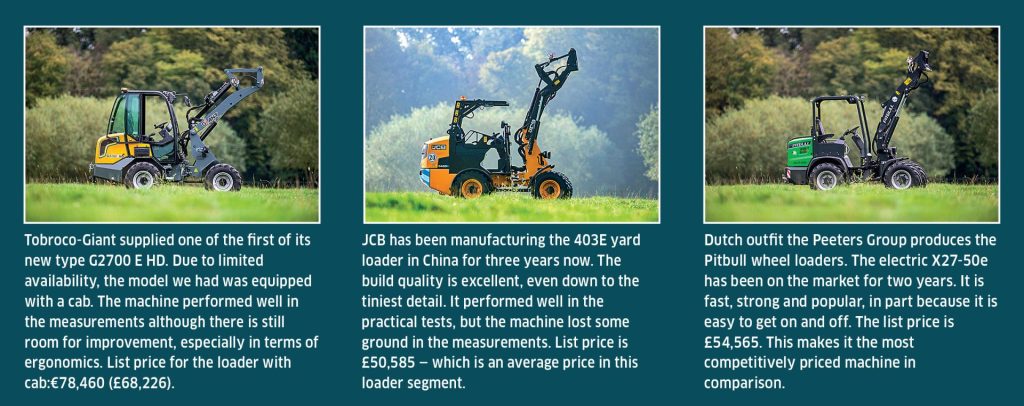

- Tobroco-Giant G2700 E HD

- JCB 403E

- Peeters Pitbull X27-50E

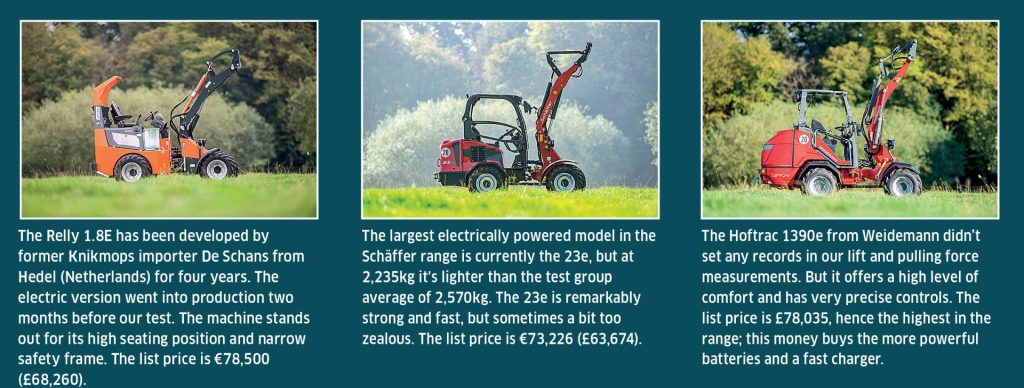

- De Schans Relly 1.8E

- Schäffer 23e

- Weidemann Hoftrac 1390e

Our focus here is not on examining the good and bad of diesel versus electric; it is more about how the battery-powered machines compare to each other. To get some hands-on practical experience, we brought the half dozen machines on to a Dutch dairy farm where they were used for four weeks.

Apart from the absence of an exhaust, and a modest tweak to the model-identifying decal, there is not much to give the game away that these six test subjects are battery- powered. And there are hardly any major differences in operation either, beyond the distinctly audible tune of a diesel motor, although these electric machines do make noise, too — but more on that later.

The operator does have to think and behave a little differently. Since there is a pair of electric motors, one for the drive and one for the hydraulic functions, stepping on the ‘accelerator’ pedal won’t help. Instead, the ground speed is determined solely by the pedal … and the working speed of the boom by how much you move the joystick.

48 to 240 volts

On all of these machines, the battery is located in the space vacated by the engine. Giant has the smallest capacity battery with its standard 13.3kWh, but you can opt for a 26.6kWh unit as an option. Relly has the largest capacity with 40kWh as standard, which can be upgraded to a 60kWh option.

Schäffer is an advocate of a high-voltage system (240 volts); the Relly has 100 volts; JCB, Pitbull and Weidemann use 96 volts and Giant 48 volts. Although not extensively tested here, it is worth pointing out that battery capacity doesn’t necessarily equate to how long you can operate on a single charge. This means you really need to test the machine on your particular business, as battery uptime varies significantly among the individual makes.

Relaxed at work

The Pitbull X27-50E impresses with its seating area and cab. This is partly thanks to the low height — it is only 67cm from the ground, making it easy to get on and off. The slim and adjustable steering column is also appealing, as it offers plenty of room for long legs.

Relly also performs well in this category: while the very spartan safety frame is a disadvantage, it does make it very easy to get on and off as well as being good for all-round visibility — there’s no frame in the way, but it has good steps and handles.

Weidemann also impresses with its steps and offers the best overall comfort — thanks to using high-quality materials, convenient adjustment of the steering wheel and a very good seat. But visibility is restricted.

On the Schäffer machine, lankier operators criticised the lack of legroom. Tall users may also bump/bash their heads on the upward-swinging safety doors when getting on. On the Giant, the design of the full cab, and here especially the right A-post complete with the console, restricted legroom and access, so the Giant lost some points in this area.

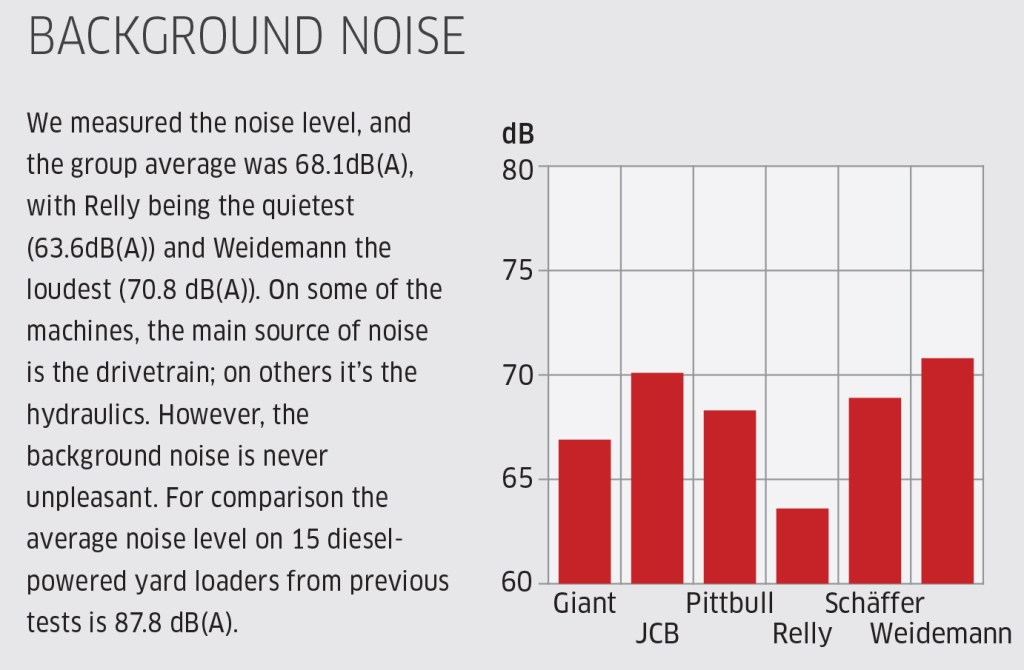

Not silent

Working without a droning background noise is really nice. While these loaders are quiet, they are not silent (see “background noise” for individual results). Working at 8.0km/hr, the average measured noise level was 68dB(A). Comparable diesel-powered loaders in this bracket average 87.8dB(A) — a massive difference. Among the test gang, the Relly 1.8E was the quietest at 63.3dB(A), while the Weidemann Hoftrac was the most vocal at 70.8 db(A).

Nearly all the manufacturers stick with a hydrostatic drive, Schäffer being the main exception with an electric motor, which it says boosts efficiency; unfortunately run and charge times were not measured during the test.

They do all use an electric driven oil pump. The advantage of this concept over a direct electric drive is that all of the engineering development costs are kept relatively low, as manufacturers can use the same axles and hydraulics from their diesel machines. In addition, the concept is tried and tested and operates precisely, with pleasant and simple operation.

Get up and go like a diesel

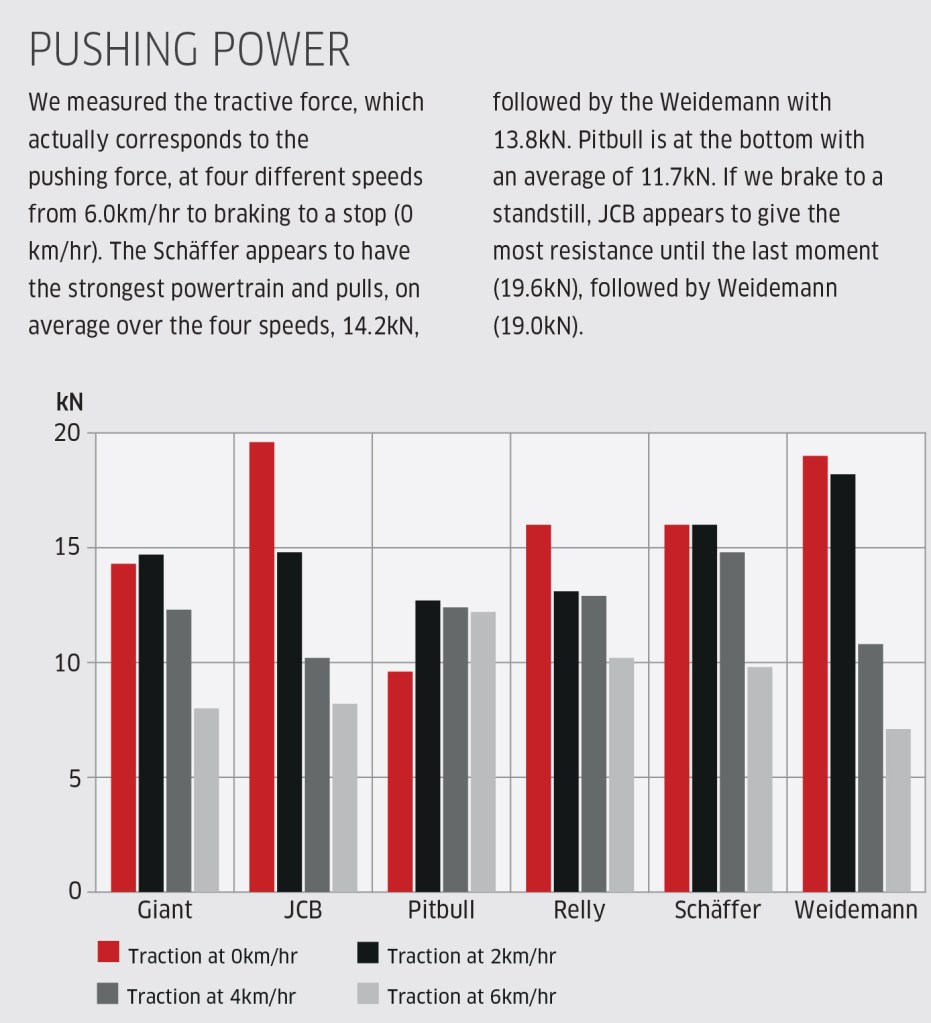

The tractive force or pushing power was measured at ground speeds between 0 and 6.0km/hr. The measurements are shown in the ‘Pushing power’ graph. Schäffer is at the top of the game with an average 14.2kN, whereas Pitbull returns the lowest average value of 12.0kN.

Contrary to what you might expect, electric loaders do not develop higher pulling or pushing power than the diesel machines: at 15.7kN, the average tractive power of the diesel-powered versions of these loaders is about 2.7kN higher than that of the electric machines.

At top speed, the JCB, Pitbull, Relly, Schäffer and Weidemann reach just under 20km/hr, while the Giant G2700 HD E is only slightly slower at 17km/hr when flat to the mat.

Dispelling another misconception, electric loaders do not accelerate any faster; on the contrary, they need on average 20% longer to go from 0 to 5.0km/hr. The exception here is the Schäffer 23e model; indeed, if you select Power mode and stamp on the accelerator it will actually lift the front off the ground.

Driving stability

Driving stability is a crucial aspect for a yard loader, so the machines were driven over an uneven test track. Stability depends not just on the weight distribution, but also on the track width, tyres, boom geometry and the overall design. The response of the accelerator also has a part to play.

Relly scored the best in terms of its driving stability, closely followed by Weidemann and JCB. Five of the loaders oscillate at the pivot. Only Pitbull relies on an oscillating rear axle, which didn’t prove to be a hit with the users.

Motor power is always available

As the oil flow in an electric yard loader no longer relies on engine speed, the full oil capacity is always immediately available. This makes the machine very responsive to joystick movements; however, when driving on uneven ground, it can be quite tricky to make smooth loader movements from the proportional-control joystick.

We loaded several trailers with sand using the test machines. Here our measurements showed that the Schäffer 23e had the most powerful drive, filling its bucket effortlessly. At times it was almost too responsive to operator demands, though switching to Eco mode could have improved this. What we liked about Weidemann and JCB was the high work rate of the remote services. The Weidemann Hoftrac stood out for its slow, smooth response when changing direction.

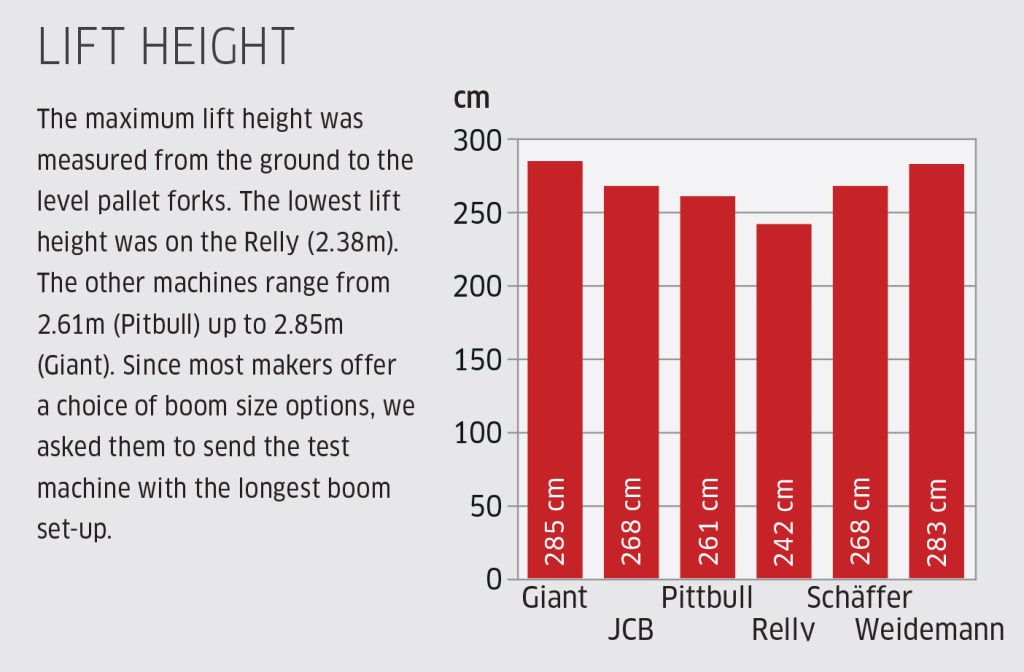

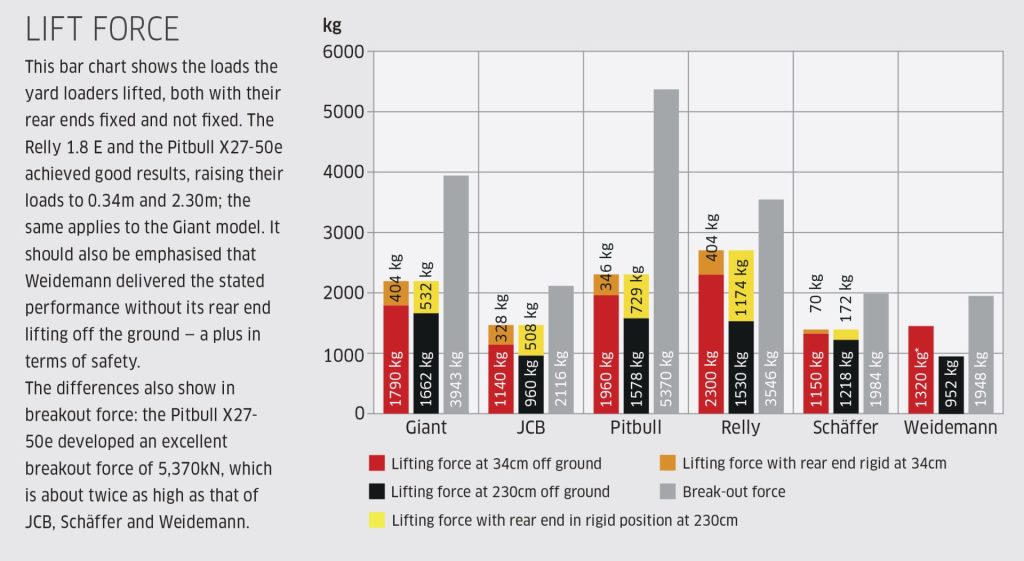

Different lifting forces

We also measured the maximum lift force and the breakout force of the crowd/dump cylinder on the back of the pallet forks (“Lifting force” graph).

The differences are considerable: at ground level (34cm), the Relly 1.8E lifted the most (2,300kg), followed by the Pitbull X27-50e (1,960kg) and Giant G2700 E HD (1,790kg). The JCB 403E achieved the lowest overall lift capacity at 1,140kg. The 1390e from Weidemann lifts more than 1,450kg, but is best balanced, because the rear wheels always stay on the ground, a plus in terms of safety.

As we are on safety matters — with its rear end secured, the 1.8E from Relly lifted the heaviest load (2,704kg), followed by Pitbull (2,306kg) and Giant (2,194kg).

When we measured at a height of 2.30m, Giant is the top performer here (1,662kg), followed by the Pitbull and Relly machines.Weidemann and JCB bring up the rear in this section of the competition, lifting about 955kg.

Summary

The comparison of the six electric machines revealed differences in performance and also similarities, such as the low noise level or control responsiveness. Yet, contrary to what we anticipated, the cycle speeds are no faster than those of a diesel-powered loader.

Bob Karsten, Bas van Hattum, Tapio Vesterinen, Eemeli Linna, Per Magne Tøsse, John Christensen

For more up-to-date farming news click here and subscribe now to profi and save.