There are a lot of firsts on Krone’s new-from-the-ground-up combi baler, the HDP CV165 XC … from the driveshaft power transfer to the 41-knife chopping system and the high-speed wrapping arms.

KEEPING IT BRIEF

- During our driving impression, it took 42 seconds to make and wrap a 1.30m bale. The wrapper applied six layers of film in 24 seconds.

- It weighs 8.9t, but it looks like a bigger machine. There are three tyre sizes available.

- One of the pre-series machines was working in Ireland this season.

Knowing it had to do something quite different to make it stand out from the combi baler crowd, Krone went back to the drawing board to come up with the CombiPack HDP. We caught up with one of the pre-series units in some dry first-cut grass, where it was able to average a completely wrapped 1.30m bale every 42 seconds. So how does it do it?

Hitch up and pick-up

Starting at the nose, the drawbar has been kept nice and slim to maximise the amount of lock available before the tyres catch. A K80 spoon is the standard fitment.

Two hydraulic rams allow the height of the drawbar to be altered, helping it to both match the tractor correctly and be used to give some extra ground clearance when entering gateways.

The EasyFlex pick-up measures 2.23m tine to tine, while the steerable gauge wheels don’t need to be removed for transport. You also don’t need any tools to adjust the wheels’ working height.

Krone has adopted some of its BigPack square baler knowhow on the CombiPack. For instance, the five rows of tines are powered hydraulically, allowing tine speed to be manually set from 75 to 180rpm or controlled automatically in relation to how fast the tractor is travelling. A pressure relief valve gives overload protection.

The 250mm diameter crop press roller also comes from the big square balers. Sprung covering tines sit above the crop mat, guiding it towards the rotor.

Our machine had the optional pendulum pick-up, which allows it to pivot with 14cm of travel on either side for much improved contour following. One final pick-up point: plastic stripper bands are used between the tines, which are not cam-controlled.

Chop, chop

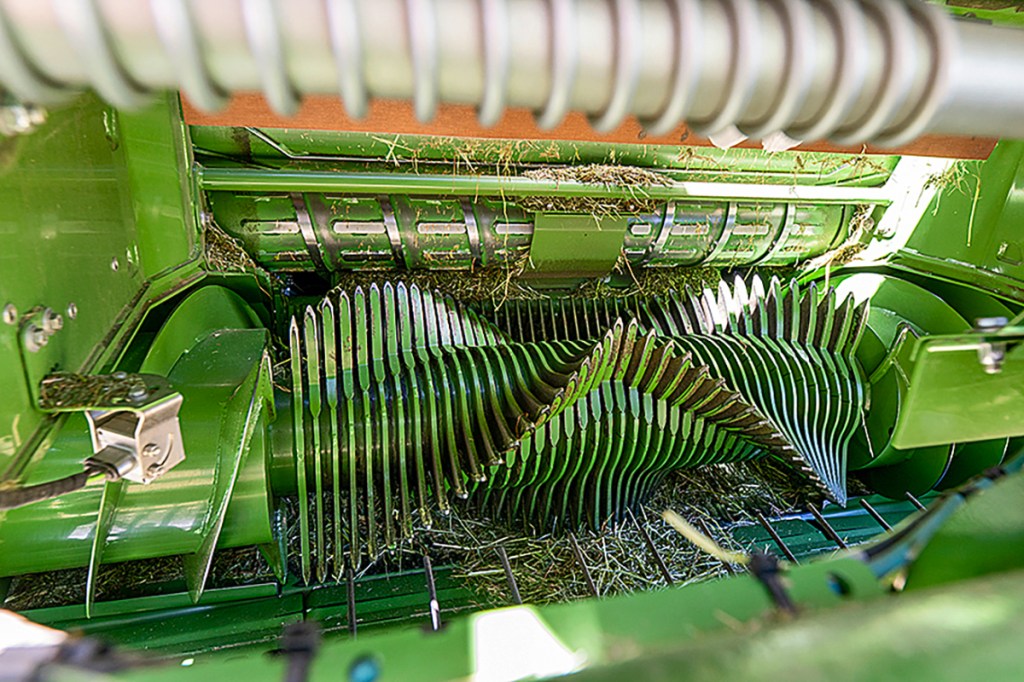

Key stats for the Hardox steel rotor are a diameter of 530mm and width of 1.20m. It has integrated augers on either side to help feed the crop to the middle.

Krone has managed to squeeze 41 knives into the CombiPack, allowing it to claim the title of the shortest chop length on the market — just 27mm when all of the knives are employed.

Knife number is manually selected from the side of the machine (0, 5, 20, 21 or 41), and they are then moved hydraulically into position from the tractor cab. The knives have individual protection. For easy-access maintenance, the knife bank slides out to the left-hand side on a drawer; a comb fills the space between the blades, so crud and debris don’t get crammed in around the knives.

Almost no chains

The driveline was another key focus area for the Krone engineers on the HDP project. When the side panels are lifted, you are not greeted with the usual array of chains and sprocket; in their place is a particularly beefy looking gearbox and shaft set-up.

As you would expect, this is a 1,000rpm machine. From the central gearbox behind the drawbar, power is transmitted around to the side using shafts and an angle box before reaching the rotor gearbox.

From here, the power branches out, with a chain still used for the starter rollers. But the belts of the variable chamber have a shaft-driven gearbox towards the top of the CombiPack.

Protection comes from a 5,000Nm clutch that sits between the main gearbox and the transfer box. Krone recommends north of 149kW/200hp if you want to start making optimum use of the CombPack’s potential, with up to a 250kW/340hp tractor being the maximum.

A full width belt is used, which is reckoned to maximise the compression and reduce losses when all of the knives are engaged. The belt is driven by three rollers which it wraps around generously to help prevent slippage.

The bale chamber parameters are all set from the cab. From here, operators can set the soft core and three different density zones, each of which provides individual pressure rates from 0 to 100%.

Net or film wrap

For maximum flexibility, the machine has two binding units, both of which can handle net and film rolls. On the screen you just select which product is loaded into each unit. You can even load both units with the same type to save time refilling if you don’t need to switch between net and film. The brake is hydraulically adjustable from the display so you can quickly adjust it to the different materials.

When inserting a new roll, the front binding unit can be hydraulically raised up and out of the way. This, and being able to lower the drawbar, results in surprisingly good access.

Controlled bale transfer

A kick arm ensures that the bale reliably leaves the chamber and via the roller table is transferred onto the wrapping table, which has moved into position to catch the ejected bale. This swift movement allows the door to quickly close so it can get back baling.

The wrapping table has four belts and four bobbins. Once the outfit is moving, the twin film dispensers can get up to their full turn speed of 40rpm, wrapping a 1.30m diameter bale with six layers in around 24 seconds.

The mission

We operated the CombiPack HDP CV165 XC with a Deutz-Fahr 7250 TTV. Walking around the machine, you will notice several features that make life easier for the baler operator:

- Up to 16 rolls of wrap can be stored on the machine. The holders are lowered hydraulically, making it easier to lift on/off the rolls.

- There is a dust-tight compartment for a toolbox at the rear right.

- On the rear left of the machine, there’s a compartment for storing a complete set of knives.

- Water tank and soap dispenser.

- Central lubrication system at the front right (standard).

- Light strips under the panels.

- There is an external control panel (rear left) for operating the wrapper and another (front left) for the binding unit and the chopping unit.

- A standard camera monitors the binding unit, while an optional camera shows the wrapping table.

We tackled some decent crops of first-cut grass. The 7250 TTV certainly knew that all 41 knives were engaged, with the engine having to work hard. On average, a bale was popping out every 42 seconds and smoothly transferred to the wrapping table to receive its four layers of film.

All of the in-cab settings are done using ISObus, either through the tractor’s display or CCI 1200 terminal — the latter is what Krone recommends for a better overview and ease of use.

Summary

Our first impression is Krone has achieved its development goal: the CombiPack HDP is capable of an impressive performance, thanks to a variety of engineering feats, most notably the new driveline system that almost does away with all of the chains and sprockets. Not having to replace chains every 20,000 or so bales is how Krone is partly justifying the price tag, which is in the region of £165,000.

The HDP impressed us in dry grass, but we are looking forward to seeing how it copes with a broader variety of crops in a profi practical test. So, watch this space.

Christian Brüse, Mervyn Bailey

For more up-to-date farming news click here and subscribe now to profi and save.