The short-wheelbase T7 is a big hitter in the UK and even more so with

Irish farmers and contractors. So, has New Holland done enough?

KEEPING IT BRIEF

- AutoCommand models will be the first off the line, DCT coming mid-2026, and RangeCommand a few months later.

- There is no hard deadline as to when the current shape T7 will stop production.

- Four models: T7.180, T7.190, T7.210 and T7.225.

- Manual spools will be available with the CVT for the first time.

- The design work started in 2023 in Modena, with various customer groups brought in to give their opinion.

You can’t argue that New Holland certainly knows how to extract its full money’s worth out of a tractor design. The T7 and its predecessors have been on the global market for nearly 20 years, ever since they grabbed the baton from the now legendary TM. Apart from a few nips and tucks, the biggest of which was the addition of the CVT AutoCommand box back in 2011, not much has actually changed.That is, until now.

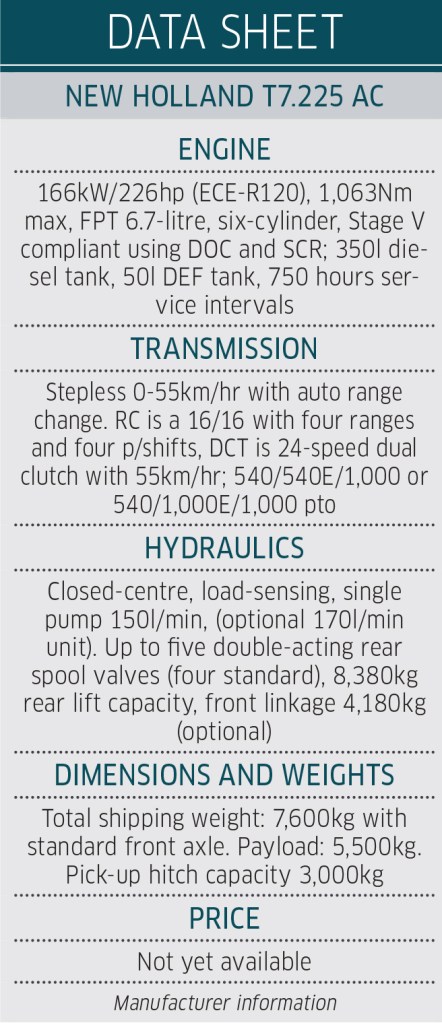

Most elements have been tweaked, yet that doesn’t include the model numbering. While the T7.175 morphs into the T7.180, it joins the ‘new’ T7.190, T7.210 and T7.225, New Holland sticking with its boosted power rating as the model identifier. FPT’s 6.7-litre engine is still providing the ponies, but the power curve adopts a different shape: it’s now flatter and reaches its max output at a lower revving 1,500rpm. The torque has also increased: for instance, the T7.225 goes from 940Nm to 1,060Nm.

An important part of the customer feedback when developing the new generation short- wheelbase T7 was to make cleaning of the cooling pack a bit easier so there’s now more room in between the intercooler and main radiator. The air-con condenser does swing open, too.

Sticking with the front

If you have been around the T7 with a front pto, you will be familiar with the rattling shaft. The dry clutch has been swapped for a wet version and the whole thing beefed up. And it is not the only thing to get extra metal: the standard 6.0t rated front axle can be swapped for an optional 9.0t beam, which has helped the gross vehicle weight to be increased to 13.5t. That equates to a payload of around 5,500kg, depending on the spec of the tractor.

Finally, New Holland has done something with the front suspension. Not only are there two accumulators so it can now react to light as well as any heavier loads, but the damping system has also been redesigned. Outboard rams on either side, connected to the chassis and axle, have more travel and offer stability when cornering, which is controlled by an electronic valve.

Sticking with comfort for the moment, the cab suspension system has been freshened up, with T7 owners now having a choice of the existing spring or a hydraulic damping system. The latter has three settings (soft, medium and hard), which are selected on the cab terminal. There is also a pneumatic cab suspension option, but it has yet to be decided if New Holland will offer this in the UK.

What’s in the box?

There will be three T7 transmission options: the CVT AutoCommand (AC), semi powershift RangeCommand (on the T7.180-T7.210) and a new option — an uprated version of the dual-clutch DynamicCommand (DCT). DCT will replace the PowerCommand, which is getting phased out with the current shape T7. Although there is no definitive deadline as to when ‘old’ T7 production will cease, we expect it to happen in the next 18 months.

Moreover, these new T7 models are being phased in, too. The first units will be the AC- equipped tractors that will be available to order from Agritechnica and arrive at dealers in early 2026. These will be followed by DCT around the middle of next year and the RC tractors in 12 months or so.

But this CVT transmission doesn’t mean the tractor has to be tech heavy; actually, New Holland is offering less. For the first time AC tractors will have the option of manual spool valves (as will the RC and DCT) together with the new, slimmer Sidewinder multi-function armrest. You can even do away with the display on the armrest, in which case more of the tractor settings and information are shown on the new higher resolution 7in dash display behind the steering wheel.

New Holland has also reworked its stepless transmission, which has used two ranges in forward and one in reverse. The automatic range change would normally occur around 12-14km/hr, as it reached max mechanical drive, and the hydro unit reset to give the infinite speed. In field work, this could lead to the tractor flicking in between the two ranges and result in a noticeable change in performance, although you could lock it into the lower range.

Extra clutch pack

To overcome this ‘flicking’, New Holland has come up with what it calls a ‘three-speed’ box by adding yet another clutch pack to introduce what some folk are calling ‘High Performance’ mode.

Pull into the field for a draft-demanding job and simultaneously press on the shift and tortoise buttons on the multi-function stick, and this will lock the transmission into the new 0.05 to 26km/hr speed band. It’s a bit like selecting a low range, which allows the transmission to utilise more of its mechanical drive for greater efficiency. Indeed, the pre-series users are saying that, when selected, tractor travel can speed up while reducing engine revs on the same job.

Once the field work is completed, it is just a matter of pressing the shift and hare buttons together, which can be done while the tractor is on the move. This allows the T7 to stretch its legs up to a slightly faster than before 55km/hr.

This, together with the change in the power curve, has resulted in a T7.225 AC achieving a Powermix test result of 257g/kWh (in our 2/2016 test with the previous generation red T7 it was 278g/kWh). That is a very good result. Better still, New Holland has also sent a DynamicCommand tractor to the DLG and this managed an excellent 243g/kWh.

Speaking of the dual clutch transmission, like the T6, this too has 24 forward and reverse speeds spread across three ranges. In full auto the tractor will skip overlapping gears; range one covers 4.0-17km/hr. There is also a brake-to-clutch function. Those on hand at our driving day couldn’t confirm if the DCT had the ‘50km/hr’ bearing that’s in the AC tractors, but they did say the four-wheel drive prop shaft bearing is no longer a major issue.

Boosted brakes mean you need less effort on the pedals to the stop the tractor, which has double disc brakes. The rear hubs are taken from the long-wheelbase tractors with a choice of flange or bar fitting. An exhaust brake remains on the spec sheet.

More backend chat

New Holland says that the initial customer consultation groups hadn’t mentioned the desire for a four-speed pto. So, there is still just three speeds on offer — 540/540E/1,000 or 540/1,000/1,000E. Speed selection is now carried out through one of the screen menus.

The hydraulic pump and lift capacities have changed moderately, with a 170l/min pump option and the rear lift capacities at the ball ends now 8,380kg.

The new T7’s rear is now more user friendly. Spools one to three are to the left of the top link, as are the ABS, trailer brakes and light connectors. On the right are the couplers for spools four and five together with the power socket and ISObus plus Power Beyond. The pressure relief levers on the couplers will aid connecting up hydraulic spools. Electric spool tractors have configurable couplers.

Although not on the tractors that we worked with, there’s a new pick-up hitch that doesn’t need lift rods.

The lower link arms get extra metal, and a quick pin swap allows the stabilisers to be changed between two preset widths. And the cross shaft has also been beefed up.

The office

The cab steps are now integrated into the fuel tank — standard spec tractors get black plastic tread plates, but these are aluminium on pricier Blue Power models, which also benefit from up-market seat and steering wheel designs. The cab door hinge has been cosmetically freshened up.

Rather than plucking the already freshened up and slightly bigger cab from the T7 LWB, New Holland has stuck with the same frame as before and then updated the styling and interior as well as the T7’s entire electronic architecture.

By the way, there will be three different roof tops: low-profile variant, the high-vis version with the small glass panel; and one without a sunroof. We have already mentioned the suspension options.

The air-con unit has more oomph with new outlets and a slimmer dash unit. There is some additional storage behind the steering wheel and to the right of the seat. You can also opt for a New Holland-branded cool box for the right-hand footwell. But one thing is very apparent: the materials/finish in the cab are a big improvement on the outgoing models’. Extra insulation under the floor mat reduces in-cab noise to around 68dB(A).

As mentioned, there is a slimmer version of the Sidewinder armrest, and, if you do want an extra screen, this can also be positioned just below the cab roof or on the sliding rail.

Other details

- The wiper field on the windscreen has been increased to 270˚.

- The ‘gunsight’ on the blue bonnet is more pronounced.

- As well as the change to the dynamic blue colour, the wheel rims are now silver rather than white. New Holland says this is not a cost cutting exercise but rather to accentuate the silver detail on the bonnet. A cynic would suggest that it makes things easier when blue and red tractors built on the same line also share the same wheels. Good news is that these are now powder- coated so should last longer.

- While most of the design work took place at CNH’s facility in Modena, Italy, the T7 styling came from its American wing.

- A wide-angle camera is integrated into the leaf logo on the front. A rearward camera can be added on to the back of the cab. There’s also the option to connect a Wi-Fi camera.

- Sourced from CBM, the lower link arm has two pin positions for the stabilisers, so you can quickly change between Cat III and IIIN settings.

Actual driving

We only had a very brief stint in the seat of a Blue Power T7.225 AC. In the field and on the road it seems a comfortable tractor with the controls all feeling familiar to anyone who has spent a bit of time in one of these AutoCommand tractors previously. That said, it does have a more premium feel about it. Neither job we were doing was a challenge for the range topping model, so hopefully we can actually get some more seat time in a DynamicCommand tractor once they start rolling off the line next year.

Summary

There is a lot of ‘newness’ on the latest T7 — new suspension, new transmission, new styling, new cab furniture … you get the idea. It would just have helped if New Holland had come up with some new model numbers to help differentiate it from those launched 15 years ago!

Overall, it seems the engineering team has listened to a lot of the criticism from current T7 users; it feels more premium. But it is not just that. There are also some nice details like the toolbox storage, pressure relief on the spools … it’s just the four pto speeds would have been the icing on the cake.

Mervyn Bailey

For more up-to-date farming news click here and subscribe now to profi and save.