Adding XT to the Väderstad Carrier name may be short and simple but choosing between a used trailed Carrier and Carrier XT is more involved. These variants differ not just in their chassis design but in the layout of the working elements too. Add various options and upgrades and there is a lot to think about.

KEEPING IT BRIEF

- Carrier and Carrier XT have much in common but numerous differences.

- A Carrier can be re-metalled and upgraded, making an old model a potentially sound used buy.

- Running a Carrier at speed delivers best results. Have you enough power?

- Carrier XT and CrossCutter discs increasingly popular.

- Carrier XT maxes out at 6.0m, a Carrier at 8.0m

Väderstad’s Carrier and Carrier XT are both disc cultivators but there is a difference. To help understand what that is, it is worth having a quick recap. The ‘original’ Carrier still remains a strong seller for Väderstad and, although it has seen detail change since we last took a used buying look, these largely boil down to a few more choices of disc and roll combinations (profi used machinery 01/2010). Actually, a current Carrier doesn’t differ hugely from the later variants we considered as a used buy some 15 years ago.

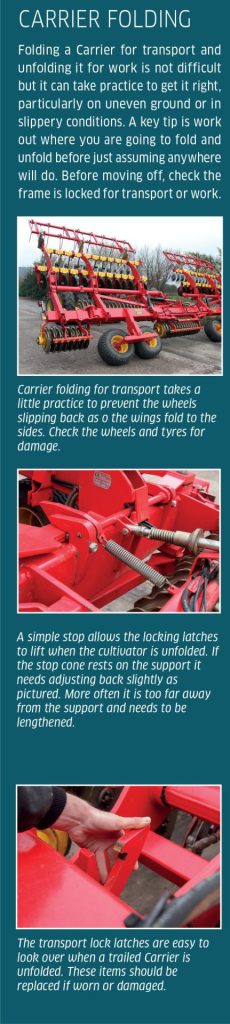

The ‘original’ Carrier remains as a shallow tillage implement, with the front tool and type of disc determining its role which tends to range from stale seedbed preparation, levelling cultivated/ploughed ground or incorporating heavier stubble and cover crops. Most UK-spec Carrier models would be tooled up for shallow stubble cultivation: a straw harrow up front, 450mm or larger cut-out 470mm TrueCut discs (for Carrier with serial number CR0004100 with the forged disc arm) and a single SteelRunner rear press being the off-the peg typical layout.

A straw harrow was once seen as a must have fit, but some will have opted for no front tool or running with a CrossBoard or a CrossCutter knife roller. The latter is aimed at chopping material, such as a cover crop, and paired with CrossCutter discs. This combo is more likely to be found on a younger machine.

On a Carrier, the front discs throw the soil to the left, the rear row of discs to the right across the full working width. In some instances, this could cause the machine to crab so from 2013 starting at serial number CR00011520 the discs were altered with one side of the machine having a left angle and the other half right moving soil to the right on the front row and then the opposite facing discs on the second row.

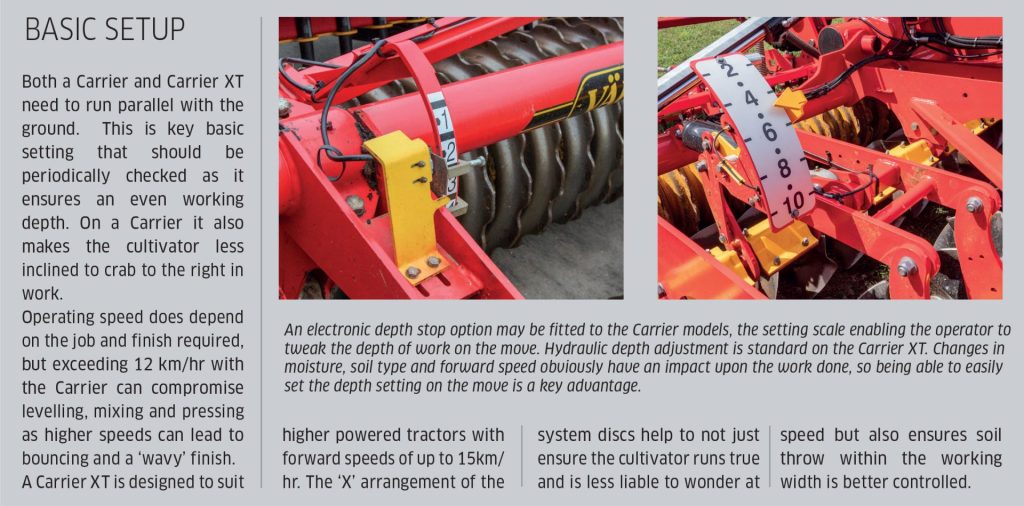

Deep wave pattern CrossCutter 450mm discs, in either standard or a more aggressive design, can be fitted to Carrier models made from serial numbers CR00014972. CrossCutter discs can easily be swapped to a TrueCut design and vice versa.

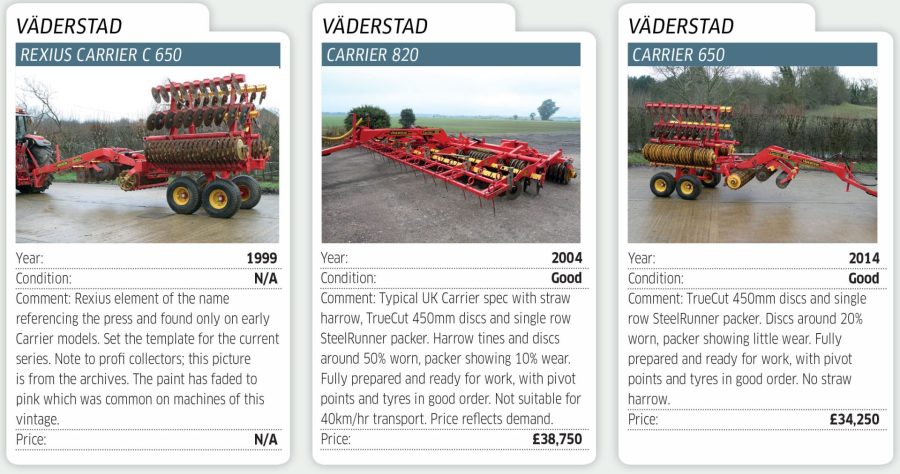

The older Carrier models were originally fitted with cast rings, as they were based on the Rexius roller – hence the name. These machines can be converted to steel rings if required, although the swap does come at a cost.

XT Carrier with X appeal

The trailed Carrier XT was first available in the UK from late 2022 with the discs mounted in a more aggressive ‘X’ pattern. The mininmum disc depth setting is 20mm for both machines.

A further XT change is the way in which the discs banks are adjusted. On the Carrier, a simple mechanical turnbuckle is used to set offset between the disc banks, with a separate turnbuckle setting the working depth.

With the Carrier XT, the discs are mounted on rotating disc axles, with the tilt and angle adjusted via a hydraulic ram. More aggressive disc angles are possible and the settings can be adjusted on the move to suit prevailing conditions.

Different chassis. Altered layouts

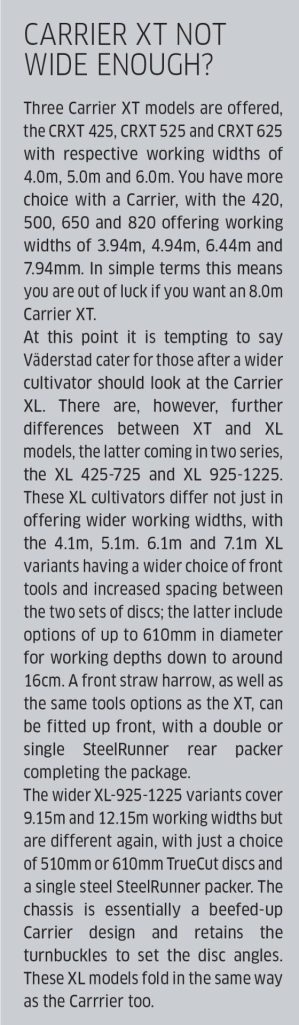

To fold the ‘original’ Carrier for transport, the unit is raised so it tilts back and rests on the horizontally mounted transport wheels at the rear. Drawing the cultivator forward causes it to fold in half and at the same time align the wheels to run vertically into the transport position. Unfolding is a reverse of the fold. A Carrier XT has more conventional wing folding and hydraulically lowered transport wheels. A hydraulic lock secures the wings in transport.

The original Carrier has the three main working elements or zones. These can vary but the UK default set up as previously mentioned will typically have a straw harrow up front, discs in the middle with a single SteelRunner packer at the rear. A straw harrow may be left off but most users suggest one is a ‘must have’ feature.

The alternative CrossCutter knife roller or CrossBoard heavy levelling board front tools are also offered, the latter typically specified by those working into ploughed or heavily cultivated land. Front tools can be retro-fitted, removed or swapped to a different type very easily.

A Carrier XT has no option of a straw harrow up front, with just the choice of a CrossBoard (which is the default fitment), or a CrossCutter knife roller. Discs follow and are easily swapped between the options on offer. When it comes to the rear packer, choices include a Double or Single SteelRunner or a Double or SIngle SoilRunner. A following harrow is a further option. A single row SteelRunner press with following harrow is a common Carrier XT spec choice; you don’t have the option of a following harrow with a Carrier.

Added beef

It is rare for a business to swap to a lower powered tractor come replacement time, with many an older Carrier getting dragged along with more horsepower than was on offer when the cultivator was first purchased. Shorthand for saying the maximum suggested 12km/hr working speed for a Carrier is more easily achieved in challenging conditions with a powerful tractor up front.

A Carrier XT has the added strength to cope with more power and has a suggested maximum working speed upped to around 15km/hr. Used buyers should perhaps consider a wider Carrier 820 with a more powerful tractor to meet required productivity rather than working the tool faster. At too high a speed, the work is compromised, and metal wear can accelerate. An 8.20m Carrier 820 will suit tractors some way north of the 220hp minimum power listed by Väderstad.

Carrier XT models appear to need a bit more power up front, an CRXT 625 having a minimum power requirement of 220hp plus. This is a relevant used buying point when considering either a Carrier or Carrier XT. The latter are built to handle more power and are likely to need a bit more pull per working metre too. This is due to the XT variants having the ability to be set up to move more soil, and at a greater depth. As is so often the case, how a machine is set up and the conditions in which it is working all impact upon the power needed up front.

As we outlined some 15 years ago, the way in which the Carrier has been employed continues to evolve. The original Carrier was initially promoted mainly as a shallow cultivator ideally suited to producing a sterile seedbed. These days, with a varied combination of tools and packer, a Carrier or Carrier XT can be used for light cultivation with good consolidation through to shallow working down heavy rape stubble or incorporating cover crops. A key Carrier XT advantage over the original Carrier is being able to move more soil and work up to 30mm deeper.

What about developments?

Over its lifetime, the original Carrier has seen a number of changes, such as improved bearings, changed disc arrangements and alterations to the frame and rear packer. Some upgrades can be retrofitted to early pre-2010 Carriers, the later built units benefiting from the key changes to keep them up to date.

A point to note is that Väderstad make it relatively easy to both refurbish and update a Carrier.

The Carrier XT is a much more recent design, with used examples just starting to trickle onto the market. There are no significant developments to concern a used buyer.

Straw harrows

As a used buyer, it pays to work out if you want a Carrier with or without a straw harrow as opposed to thinking it will be cost effective to retrofit one if needed; the latter will work out more expensive than securing a used buy with one already fitted. A key plus with these harrows is they will both help spread chopped straw more evenly across the working width and help distribute clumps of material ahead of the system discs. In difficult conditions this can make the difference between cracking on or dealing with clumps causing blockages.

On a used buy, a straw harrow up front would typically add a premium. These days, it is more a case of you finding what you want. If you want straw harrows, buy a used Carrier with them already fitted.

Front tools

Both Carrier and Carrier XT can be fitted with a CrossCutter knife roller or CrossBoard heavy levelling board; the straw harrow option only being offered on the Carrier. As a used buyer, be aware that the front tools can be swapped relatively easily but at a cost. If you want a CrossCutter disc to marry up with CrossCutter knife roller, the latter are an ‘affordable’ swap, but switching from a CrossBoard to a CorssCutter will be costly enough to make buying a XT with one already in place a better idea.

System Discs

Väderstad went through several changes to the Carrier ‘System Disc’ legs and bearings, moving from a fabricated steel leg to a forged unit in around 2006. This design was the first to move from 430mm discs to the V55 steel 450mm units still offered on current models. The disc bearings also saw several changes, mainly to the seals to improve their working life. A forged leg will accept current bearings and be long enough to accommodate 470mm discs on a Carrier but check if you want to fit a CrossCutter disc. These will only fit Carrier models with serial numbers from CR000 14972.

Rear packer – SoilRunner and SteelRunner

The rear packer fitted to a Carrier initially included a choice between a cast ring and solid SteelRunner, the latter first offered from 2003 and standard in the UK from 2005. As cast ring rolls will now be a rare used find note spares will still be available through Väderstad but not necessarily from dealer stock. Väderstad improved the design of the press bearings, incidentally, so expect the part number of a new replacement to be different if renewing an early original bearing.

Carrier SteelRunner packers made up until 2022 have each separate ring section linked to form a single unit by pressure applied during assembly. A purpose made clamp is used by dealers to keep the roll sections together before the bearing housing is slackened for removal, a farm ‘bodge’ seeing a ratchet strap used to do the same job. Take the bearing off without clamping the press together and it can be dangerous. It pays to seek advice before just assuming the job is as simple as it looks. Even if you can get a bearing off you still need to clamp the rings together to refit the bearing. Make sure the bearing’s outer rubber seal is in good shape. If it is damaged, assume the bearing will need renewal.

Carrier XT and Carrier 2022 model year SteelRunners are of a different design and not assembled under pressure. The bearings are also different, with improved seals.

Carrier models made up until 2005 could be fitted with a cast ring packer. On cast ring rolls, the bearing is easily replaced, but it is important to ensure the axle is correctly shimmed to ensure the rings interlock tightly on reassembly.

Drawbar and frame

A Carrier frame is arguably best checked in its transport position as it can make it easier to look over all pivot points for wear and evidence of routine greasing. A point to note is the way the cultivators fold. As previously mentioned, the tilt to fold system is unique to the Carrier.

If any of the pins that secure the system discs to the main frame have a fractured lynch pin it tells you the mounting pin is seized through a lack of routine greasing.

The lateral ‘top link’ style adjusters that set the System Discs work in the same way on all models, but the earliest Carriers have a reduced clearance between the front and rear disc set plus a pivot system to enable the lateral setting to be adjusted.

On early Carrier models, the front section of the system disc frame was a solid piece of steel. This would typically be adjusted so it ran parallel to the drawbar. All subsequent models have a spring steel front frame. This is designed to flex laterally and should be set to allow the front and rear discs to track so they produce separate furrows. This simple setting is often overlooked, so check. There should be a noticeable offset for the leading set of discs when viewed from the front.

Folding Carrier models also need to be folded correctly, and the locking latches must be in good shape. The folding process is not complex, but it does demand correct adjustment. It is important to ensure the various sections lock together cleanly in work. Careless folding can damage the cultivator frame, so look for damage.

Also take a good look at the inner edge of the wheels. When the unit is folding, the towing tractor needs to roll back to allow the Carrier frame to approach vertical prior to drawing the unit forward to bring the sections together for transport. If the tractor is prevented from rolling back, it puts a great deal of strain on the wheels and tyres. If you are not used to folding a Carrier, seek advice. It’s a simple job that is easy to mess up.

Carrier XT cultivators have conventional wing folding.

Carrier XT – used finds will be hard to find

Carrier XT models are still relatively new, so ‘used’ examples are more likely to be ex-demo units. This can mean there may be a broader range of spec choices on offer than would be the case with a Carrier. As previously outlined, these models tend to follow a more conventional harrow, disc and press layout. With an XT, you are more likely to come across front CrossCutter and CrossCutter disc models. Also look out for models fitted with a BioDrill. This combination is sought after for establishing cover crops and other bio seed uses.

Regarding finish, Väderstad paint has always lasted well. The paint on older models could fade to pink, a point to note if you are looking at a pre-2005 Carrier. For some, this is the only way to spot an old machine from a more recent model.

Summary

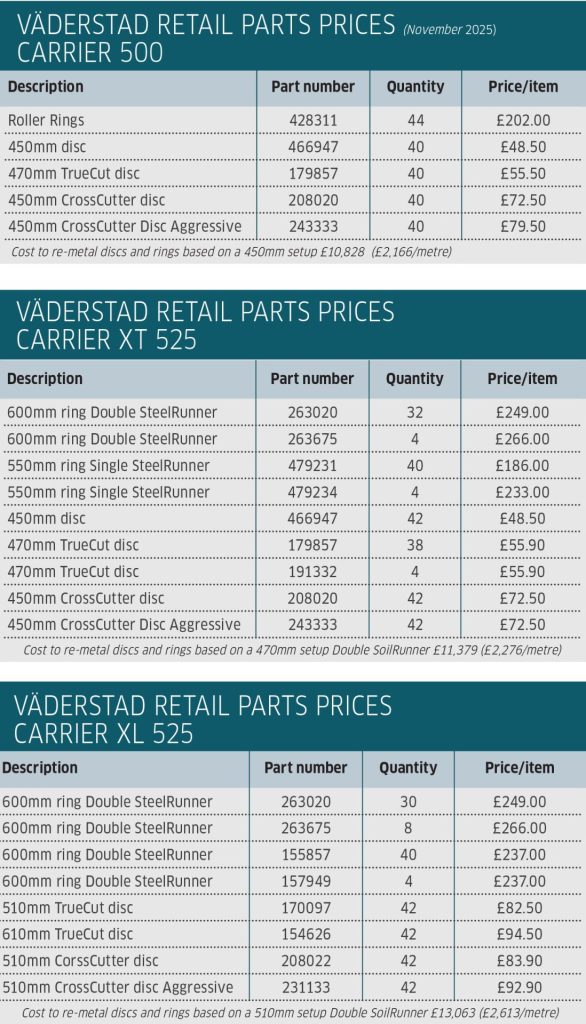

This is the third time we have taken a used buying look at the Väderstad Carrier. No apologies for this. The company has continued to refine and tweak these popular tillage tools, making used examples a top used buy. This is reflected in prices. Decade old Carrier 650 and Carrier 820 cultivators with fresh wearing metal seldom dip below £30,000 and £35,000 respectively, those of a similar age needing some workshop love and new wearing parts still commanding respective sums of perhaps £20K and £25k. As to earlier examples, a great deal will depend upon condition. A 20-year-old or more 5.0m Carrier 500 will be in the lower teens. Parts are available for all variants although these can appear expensive when looked at individually. Best to look at a ‘per metre’ costs to get a better idea of the price to renew worn metal.

The Carrier XT is a different animal to the Carrier. It can work deeper, and it can move more soil. It is not a better cultivator but a variation on the established Carrier theme. As a used buy, it is the Carrier that will be easier to find. Bad news if you want an XT. Good news if you want to have a simpler choice.

With thanks to Turney Agriculture, Middleton Stoney, Oxon and Tom Wyles, Väderstad UK.

For more up-to-date farming news click here and subscribe now to profi and save.