Trailed spreaders have a strong following in the UK, both for fertiliser and lime use, their extra carrying capacity providing a significant output boost compared with mounted units. Another benefit is users can still retain control in the fertiliser market and choose from different suppliers and granule quality to suit budgets and crops, which isn’t always possible with liquid fertiliser applications.

A trailed spreader can represent a significant outlay and has traditionally been considered to be a contractor’s machine, where the primary need is to cover large acreages in a tight time window.

“The majority of machines we supply go to contractors,” agrees KRM managing director, Mike Britton. “But as farms get bigger the efficiencies of running a larger trailed machine outweigh the cost and we’re seeing an increasing number going onto farms.”

“While they are a ‘seasonal’ product, most customers would use them in the spring and the autumn – for a contractor the spring season could be February to May and the Autumn season starts as soon as the combines are rolling and only stops when it gets too wet, so that could be July to November. So, many contractors are using the machine most of the year.”

The versatility to spread a range of materials with a reasonably quick switch over, the use of ISObus control for easy operation and integration with prescription maps and the option of the latest border spreading systems also make these machines a more attractive prospect.

AGRISPREAD

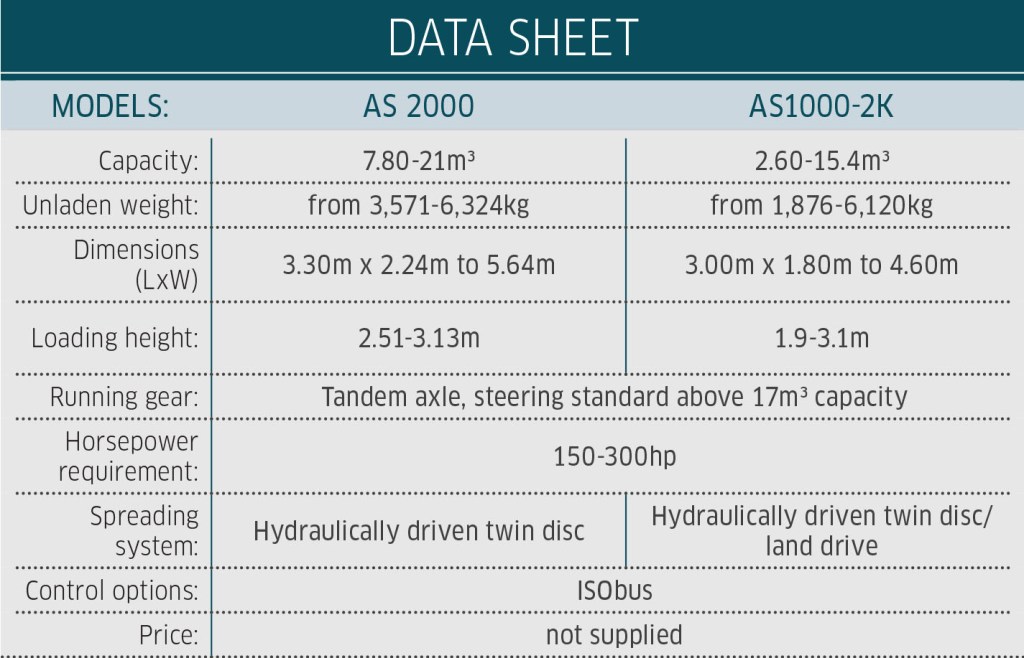

Supplied by Dales Agri Sales Agency in the UK, AgriSpread offers a range of AS Series mechanical land drive and hydraulic drive ISObus twin-disc spreader models options, capable of spreading fertilisers to 48m and lime/basalt/bulk dry flowable products up to 12-16m.

Features include large flotation or tractor grip wheels, stainless steel key components, full stainless-steel hoppers and a robust build for stability in lime/basalt spreading and bulk products.

Available in 16 model versions with a large choice of hopper capacities in two ranges: The AS2000 Series with hydraulic drive and ISObus and the AS1000-2K Series with land drive and hydraulic drive ISObus options. All models feature hydraulically driven spinner discs that give optimal control of the spinner disc speeds for normal spreading, boundary spreading and section control in single or twin floor belt options.

Using dynamic automatic rate control, the product flow is constantly measured and automatically adjusted to maintain a precise application rate per/ha. Variable rate application is compatible with precision farming prescription maps and available as standard on all hydraulic drive ISObus models.

Load weight cells are mounted on a double chassis design and available in ‘read only’ and full ‘ISOBUS auto rate control’ versions.

Alpler

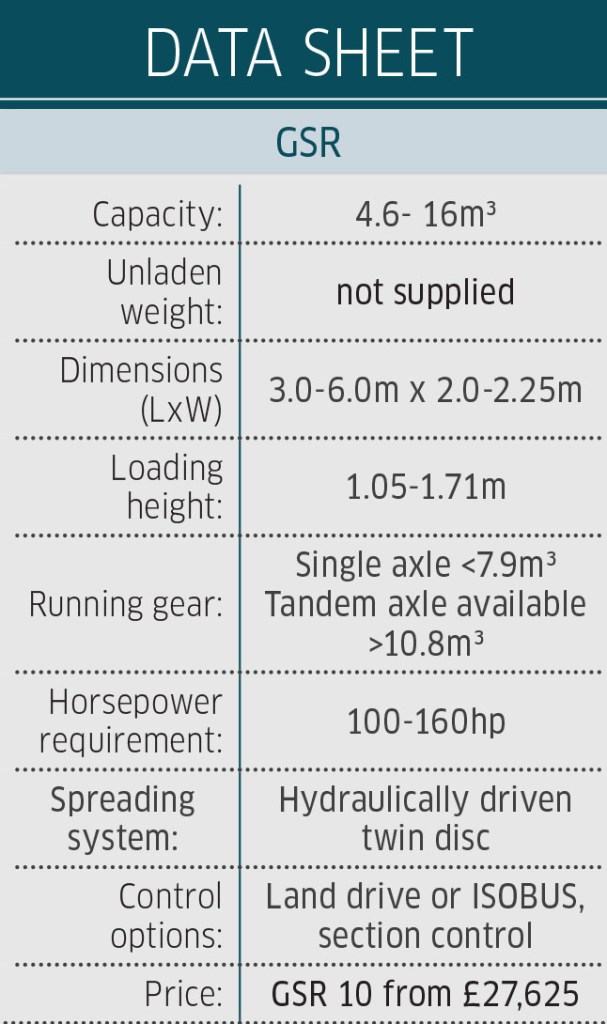

Spreaders follow the Transpread design aimed at simplicity and durability using proprietary parts that are easily sourced, says the company.

This features a stainless steel or mild steel hopper and fertiliser engaging components, Eaton motors and a twin feed chain covered by a five year warranty. Land drive is standard to match application rate to forward speed, with an open discharge design and adjustable door to allow product to flow to the spinners. Spread widths of up to 36m can be achieved with pelletised products, 24m with urea and 18m with lime.

A plug and play option offers ISOBUS control, and an inspection ladder and window allow the operator to keep an eye on the hopper and its contents.

AMAZONE

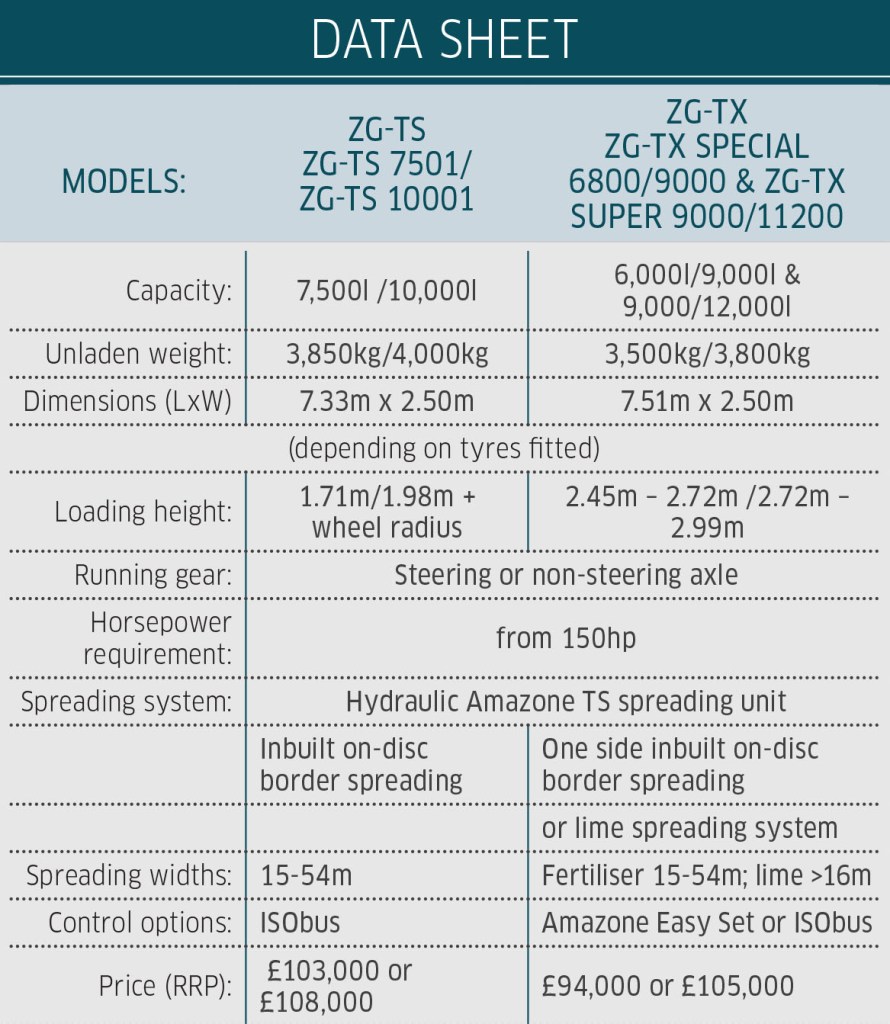

The trailed spreader line-up from Amazone consists of two primary machines, the ZG-TS and the ZG-TX. Both machines use the same TS spreading unit found on the flagship mounted spreader, however the ZG-TX has the option of quickly removing the fertiliser spreading discs and shroud and swapping to a lime spreading unit.

The ZG-TS is optimised for fertiliser with the same optional extras as the mounted ZA-TS such as ArgusTwin, BorderTS, WindControl and Profis online weighing system. The ZG-TX still benefits from the TS spreading unit with one side on-disc border spreading.

Use of the ZG-TX can be extended out of the fertiliser spreading season by converting to a lime spreader through a simple change on the back end, taking as little as 40 minutes to changeover.

BREDAL

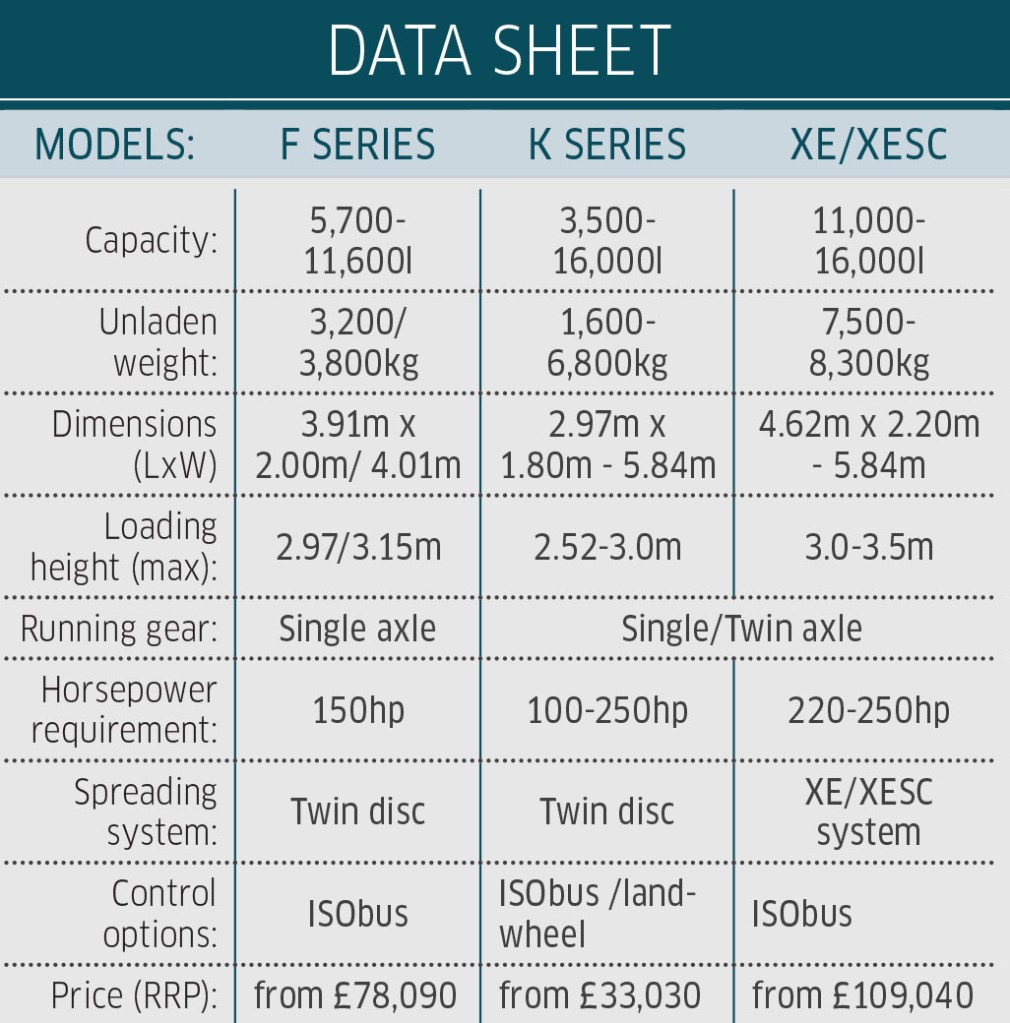

Distributed in the UK by KRM, The Bredal F series has been designed specifically for fertiliser. This machine has two floor belts so it is able to adjust the quantity of fertiliser being supplied to each disc, this, alongside automatic down chute adjustment and hydraulic disc drive, provides section control and allows the headland spread pattern to be adjusted from the cab.

The XE has a 6.00m wide folding spread unit to increase the working width. Material is transported from the hopper to the discs via lateral conveyors. The machine can be used to spread all products including lime, fibrophos and fertiliser.

The XESC version has section control achieved with hydraulic drive discs and electric down chute adjustment. In order to vary the quantity being supplied to each disc the whole spread unit slides side to side, altering how much material comes from the main belt. The main belt can also be adjusted to supply more or less.

The K series single floor belt lime spreader remains the most popular choice, providing the greatest flexibility to spread a wide range of products for the least cost, says KRM’s Mike Britton. “It is highly customisable with a wide range of optional equipment to suit specific applications. The latest development is the addition of load sensing hydraulics. While hydraulic drive for the floor belt has been relatively common for a number of years, we’re finding more and more customers also choosing hydraulic drive discs. This provides greater adjustment and is monitored and controlled through ISObus.”

KUHN

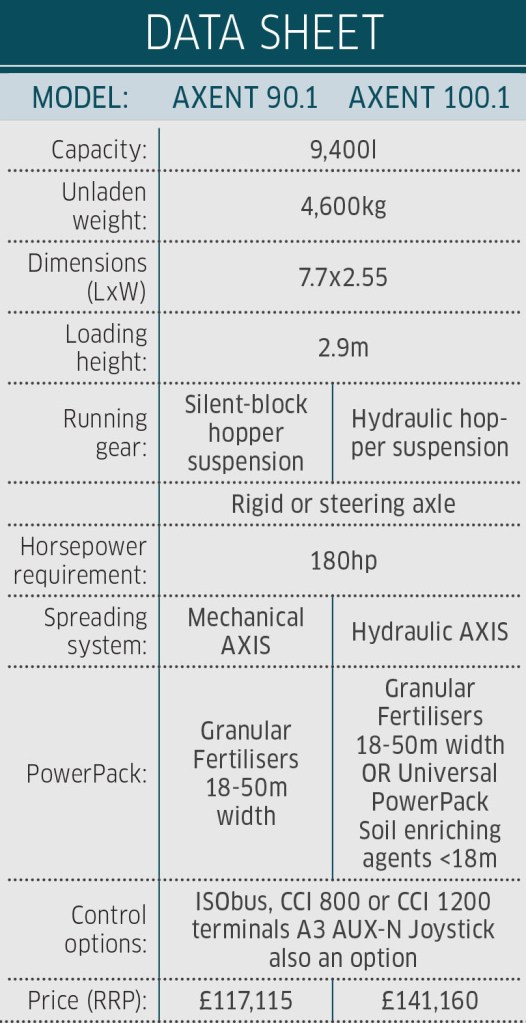

Kuhn’s Axent range has two models that feature the same capacity and dimensions but differ in the mechanical or hydraulic design of the spreading system.

Axent spreaders can apply up to 400kg/ha of ammonium nitrate to 36m, at speeds over 20km/hr, with a 24ha capacity from the hopper. The hopper features four integrated weigh cells and the Coaxial Distribution Adjustment accounts for variations in ground speed and working width to ensure precise application. A 17rpm agitator regulates supply in the hopper.

To ensure all fertiliser is spread, an 800mm-wide floor belt supplies a pre-chamber above the discs and initiates when the fertiliser level becomes low. The Universal PowerPack spreading system allows applications of chalks and powders, spreading up to 18m wide with a hydraulic beater to improve the product flow.

Four SpeedServo electric motors adjust the drop point and outlet, opening 2.5 times faster than a conventional cylinder, says Kuhn. This improves opening and closing precision and adjusts rates when working on different size fields and plots. The Electronic Mass Control (EMC) regulates the flow rate independently to the left and right disc, using sensors that measure the torque drive to each side. The sensors immediately register if there is a blockage and adjust the opening to achieve the desired rate.

VariSpread Pro has two SpeedServo electric motors to adjust the working width continuously as the spreader passes onto the headland. The system can reduce the application rate gradually over eight sections. OptiPoint Pro calculates the opening required based on fertiliser type, working width and ground speed, and initiates the opening and closing points to provide complete coverage.

SKY

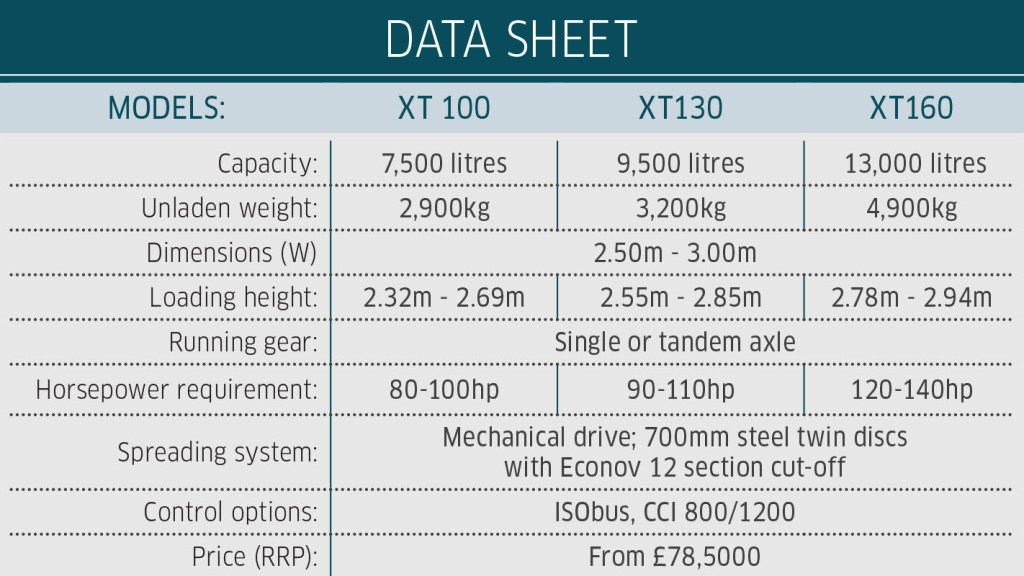

Sky Agriculture’s XT range offers working widths up to 50m and rates up to 5t/ha using a mechanical belt drive to twin spreading discs with three ratio gearbox allowing low application rates.

Belt drive by crown and pinion gives a flow rate proportional to forward speed under electronic control. The Econov section cut off design originated by Sulky offers 12 sections and a range of spread patterns.

The ISObus Quartz 800 console manages the sections and spread pattern and offers GPS variable rate and independent side control.

SPREADPOINT

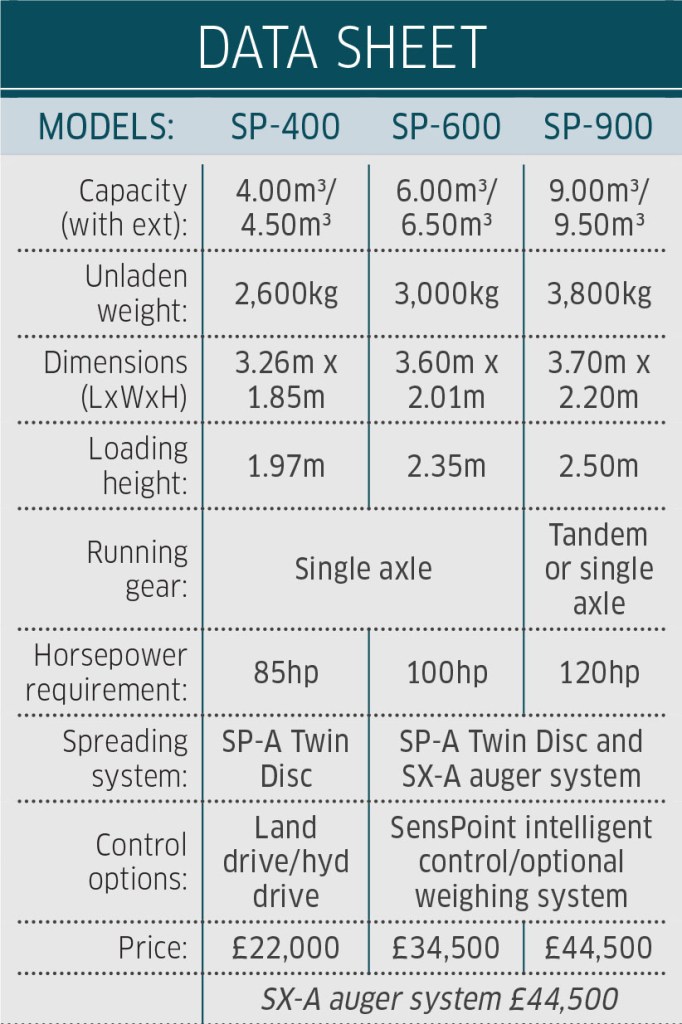

SpreadPoint offers bulk spreaders from simple heavy-duty entry-level SP-400 machines for individual use, to the SP-900 tandem axle with SA-A auger system.

SpreadPoint’s modular system means that the SP-A twin disc unit can be replaced with the SD-A salt and grit applicator for winter maintenance.

The SP-A heavy duty stainless-steel twin disc unit boasting 6mm vanes, vane holder and discs can with stand materials such as sand, grit, stones and crushed basalt., while the SX-A Auger systems can spread materials such as Fibrophos or Gypsum.

PNEUMATIC SPREADERS

Boom applicators widen spreading windows and can apply nutrition when spinning disc machines are halted by strong winds. Wide working widths can compete for output with using a sprayer to apply liquid fertiliser. Growers are also utilising boom spreaders for establishing cover crops or SFI mixes.

HORSCH

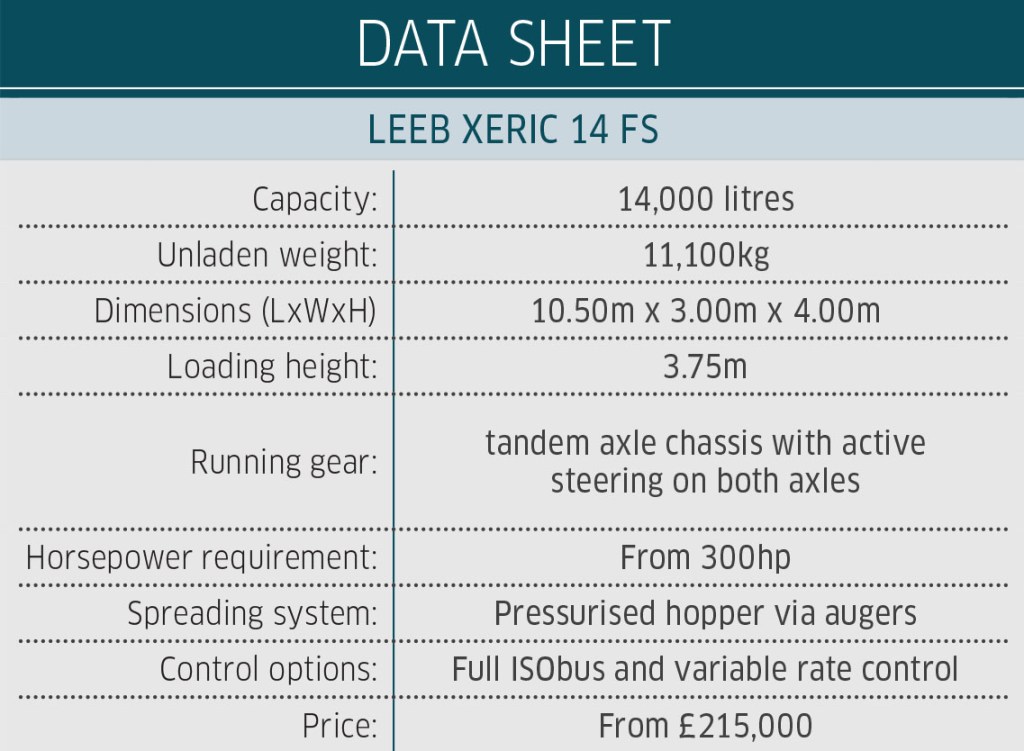

The Horsch Leeb Xeric 14 FS, the company’s first pneumatic fertiliser spreader, will enter series production for the 2026 season.

Alongside the established working widths of 36 and 48 metres, a new 39-metre version now completes the range. With a 14 m³ capacity and operational speeds of up to 20kph, the Xeric features a new optional tyre pressure regulation system which can be activated while driving. This increases the contact area, significantly reduces ground pressure, and extends the operating window.

The Leeb Xeric uses Horsch’s BoomControl system to maintain boom stability across the working width. The boom continuously adapts to the terrain and is fully decoupled from the vehicle.

Fertiliser is transported from the pressurised hopper via augers into the metering box, which has a fixed water meter and is mounted on three stable weighing rods. The fertiliser enters the air flow by gravity where it is accelerated by air and transported outwards through the pipes. This allows rapid calibration according to fertiliser type. As part of the development process, additional metering augers were integrated to optimise performance across different fertiliser types, application rates and operating speeds.

The metering box houses 12 sectional augers, enabling variable application rates. Optional systems include PrecisionSpread Pro for curve compensation and PrecisionSpread Pro Plus for section-by-section variable spreading. Discharge of the Xeric 14 FS is vertical load-optimised.

KUHN

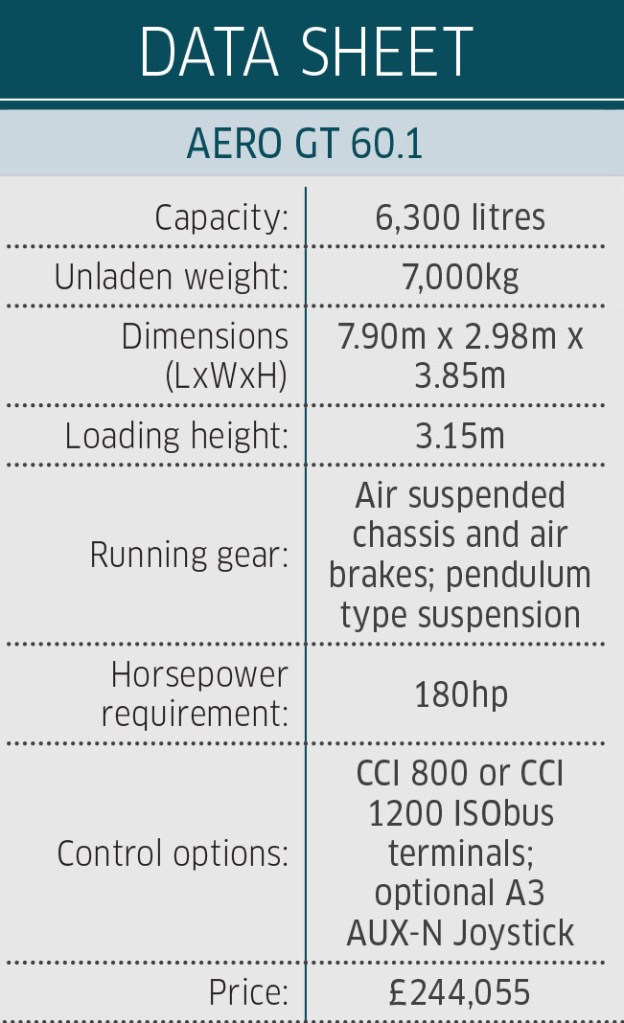

The trailed Aero GT 60.1 offers the potential of 400ha/day output with high ground speeds says Kuhn, which also offers the mounted Aero 32.1 version.

Across a 36m width, the Aero GT 60.1 has six sections, with six outlets in each.

Each section has its own metering unit, offering improved shut off at the end of each row and reduced fertiliser wastage. These sections can also apply a different rate to the others across the same pass, designed to offer more accurate coverage in accordance with prescription maps.

Fertiliser is blown to each outlet before being broadcast via spreading plates for uniform distribution and even application of lower-cost fertiliser across the machine’s width.

Two high-capacity fans transport the fertiliser to the boom ends, driven independently by the tractor’s pto.

Calibration is via a single metering unit and the data is then shared with the others. Automatic boom safety break backs at either end protect the machine from obstacles, while Kuhn’s Distance Control system adapts the boom height to the topography and crop using two ultrasound sensors.

For more up-to-date farming news click here and subscribe now to profi and save.