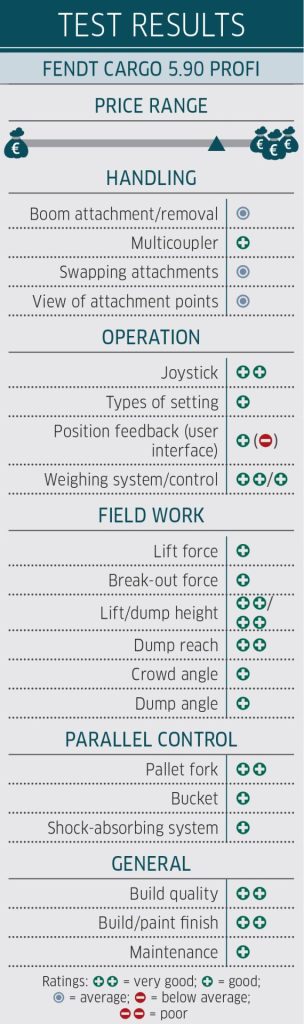

…but nothing is a must. The Cargo 5.90 Profi is part of the latest generation of Fendt loaders, which can have all of the latest handling technology options. We gave it a thorough workout.

KEEPING IT BRIEF

- New features include on-board weighing and return to dig.

- In the test, the loader impressed with its responsiveness and precise operation.

- Critical details include having to keep the Memo key pressed for too long.

- Although the boom manufacturing is carried out in the Czech Republic, Fendt says the loader is very much its own design.

One of the major benefits of fitting a tractor maker’s own brand of front loader is that it can be fully integrated to operate not just with the controls but, as we are increasingly seeing, the software as well.

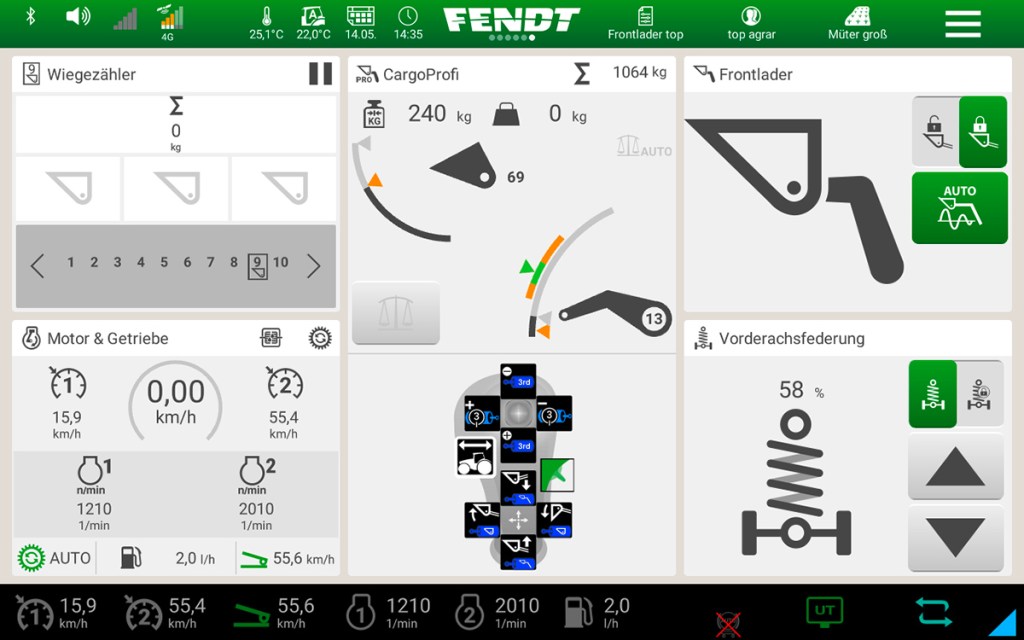

The FendtOne operating system on the 620 Vario we tested in the August issue was able to do just this, with the firm’s new Cargo 5.90 Profi front loader offering a range of optional functionality all aimed at making life simpler for the operator and boosting overall productivity. Sounds good so far; time to knuckle down on the details of our test subject.

Aim high

The Cargo 5.90 Profi is the top of the range front loader for fitting to the Vario 600 tractor series. The 960kg boom has some big numbers: for instance we measured a lift height of 4.45m at the implement pivot pin. At its maximum dump angle of 55°, there is still a usable 3.38m of lift height remaining. And with the bucket positioned level, the Cargo has a stacking height of 4.26m — all impressive stuff so far.

Mounted on the 620 Vario, the view through the long windscreen of the raised boom is very good. When lowered, the broad bonnet severely impairs your view of the loader attachment. And the bulky cross beam (measuring 160 x 350mm) also takes its toll on visibility. The camera in the front grille does help with overcoming some of this by providing a view of the lowered implement — you just need to remove the front top link first.

Plenty of power

Fendt specifies a continuous lift power of 2,950daN for the Cargo 5.90 Profi loader. Our measurements showed 2,230daN; the highest force of 2,820daN was measured at a height of 1.37m, which is okay. One reason for this variation is that Fendt measures the lift force at the implement pivot pin, while we measure 60cm out on the pallet fork. As for breakout force, this was measured at 3,220daN.

The attachment angles are also good. With the standard Fendt bucket, the Profi 5.90 achieved good results with a 47° tipping angle at ground level and 55° when the loader was fully raised. Fendt relies on a mechanical parallel lift control for the Cargo 5.90, which manages to gently control the attachment through the entire lift range.

Electronics on the Profi version offer a lot more. For example, the loader detects the boom position with the help of sensors at the pivot pin and in the left crowd/dump cylinder.

The “Memo” feature allows two positions to be saved and then be automatically and precisely controlled. However, the button has to be pressed until the attachment has reached its position — annoying.

Although the work cycles can be quickly carried out thanks to the powerful hydraulic pump (220l/min), the position feedback slows down the handling performance, so it could be faster. However, the values for the minimum and maximum lift height can be set at the press of a button.

Detailed criticism

To utilise the extra functionality to its full, you need suitable attachments — but this is somewhere we see room for improvement. For instance, the optional hydraulic locking headstock is fitted with a pawl that prevents the system from locking home in front of the hole of the attachment. This can cause problems with third-party attachments, as it restricts the space for the Euro eyelets on the attachment.

One other annoyance with the headstock is that when the latch is open, oil flow to the crowd/dump rams is automatically reduced to 25%. The good news is that the attachment no longer needs to be fully crowded back for locking.

Another minor criticism goes to the auxiliary hydraulic couplers. While their position at the front of the cross member is fine, the couplers are located too close together to comfortably use. And the couplers for the proportional control circuit — the one that’s used most frequently — are positioned on the right-hand side.

Off you pop

Fitting and taking off the loader (best done with the bucket attached) hides no surprises. Our niggle is that you need to get off the tractor twice, and that the wide bonnet makes it tricky to drive between the 104cm boom.

A small but smart detail: the spools in the Multicoupler are arranged diagonally, which is reckoned to avoid uneven pressure build-up and issues when coupling a pressurised line. Other nice details (but not unique to Fendt) are an auto dust cap and a bracket for storing the multi-coupler. Incidentally all the pivot pins are greased from the outside and have replaceable bushings.

Decisions, decisions

In Profi trim, the Cargo 5.90 comes with a wide range of operational functions, fully integrated into the FendtOne controls. This brings benefits and disadvantages, however: some of the latter can be reduced once you have gained some experience and learnt exactly what tweaks to make to the standard configuration.

In the standard factory setting, the lock on the headstock is enabled through a sub- menu on the VarioTerminal. Alternatively, this job can be assigned to the intuitive 3L joystick or one of the customisable armrest buttons.

What’s important here is that you should save the individual assignment to a specific profile. Personalising the control layout can be a bit of a challenge for less experienced operators, especially since it is currently not possible to assign icons to the buttons. To make up, you can include in the profiles details such as the automatic increase in engine speed upon activating hydraulic functions.

The boom suspension is actually quite good, although it can only be enabled when the corresponding job profile is active or after confirming the previous settings. After a bit of getting used to, you should be able to intuitively customize the controls; and in most cases the assignments are well labelled on the screen.

Taking a quick look at the operation of the front loader. The 3L joystick is really nice to use and provides three different operating levels that you can quickly switch between using the switch on the back of the joystick. Another very neat detail is the proportional control of the third service.

A button for changing the direction of travel is also integrated into the 3L joystick — very useful, as your hand stays on the joystick all the time.

By flicking the switch to toggle between the three levels of the dual stick, you have a total of 27 functions at your fingertips. The second and third level offer weighing, return to dig position and shedding functions. In short, there are plenty of options.

Dynamic weighing

Speaking of weighing, the Profi version also includes a built-in weighing system. This can be activated manually or automatically — in auto mode, weighing always takes place when the boom is in the same position.

The weight is shown on the screen for a configurable amount of time. A green bar on the screen shows the optimal lift range for the most precise weighing performance — there was only a 2-5kg variation when we checked the results. The farther that the attachment is crowded back, the bigger the green range. That said, the material can be weighed with the bucket in any position.

FendtOne also includes a weigh log that records the number of buckets and the weight. However, the weight counter is not fully integrated into the CargoPro menu and has to be operated by pressing a separate on-screen button. And there is no option for creating a menu for filling a diet feeder, for instance.

You can name 10 weigh logs individually and assign them a target weight. Sadly, the weight counter can only be viewed after creating a Task Doc job in the Fendt OffBoard telemetry system.

Summary

The stand-out feature of the Cargo 5.90 Profi is how handily it is integrated into the FendtOne controls; this offers numerous options. Once you get your head around how it works, then it is nice to use. And thanks to the responsive control, it is easy to work with the loader. On our test 620 Vario the loader proved it was designed for speedy cycle times.

The boom itself appears well put together and makes a solid impression, but it also comes at a price. The full spec Cargo 5.90 Profi is more than £21,476 — without any attachments but with a weighing system and return-to-dig position feature.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.