The Ostler K2TT is not only of sturdy build — it also stands firm. Stability comes from the telescopic front axle, which is one of several intriguing features we discovered during our test.

KEEPING IT BRIEF

- The front axle can extend by up to 63cm for additional stability.

- Telescopic model has a maximum lift height of 3.55m.

- The K2 is also available with a fixed front axle and boom.

Before we talk about technicalities, it’s worth mentioning a quick history of Ostler. Although the name is not new within the yard loader sector, the company behind it is, with German engineering business, Heitmann & Wittler, buying all the designs and trademark rights from the former Bavarian manufacturer two years ago.

Since then, Heitmann & Wittler has reworked the Ostler loader, making numerous updates. And the first unit, the K2, is now being built at its factory in Northwest Germany.

Telescopic axle

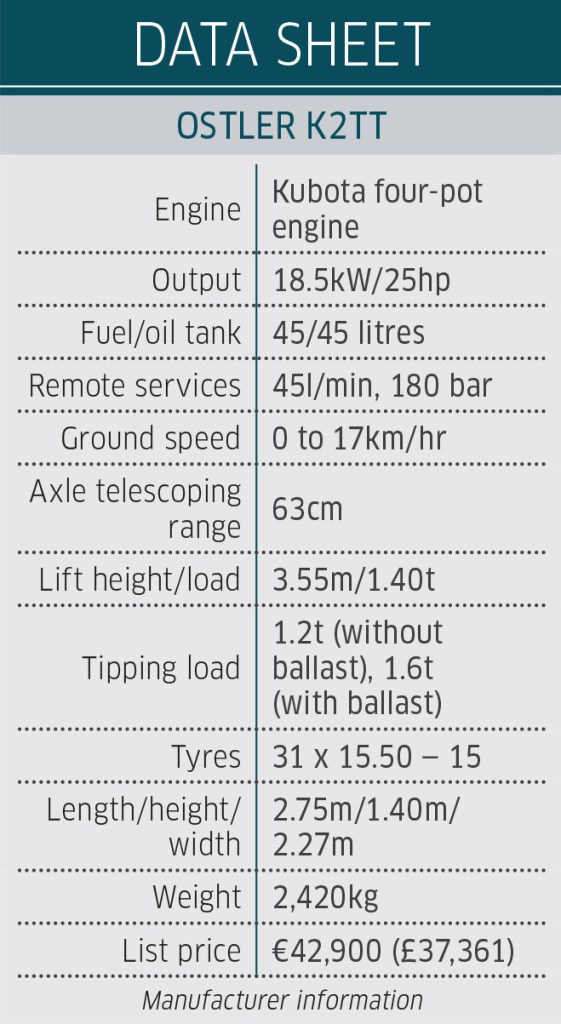

The K2 is available in four different versions: with a fixed or telescopic boom and also with or without an extendable axle. We operated the K2TT model; this has both of the hydraulic extendable options for boom and front axle.

Of the two, the €4,000 optional telescopic axle is that bit more interesting. This is a modular unit, so it can be simply fastened to the front chassis with 12 bolts, helping ease manufacturing between the two axle set-ups. The lifting and pushing forces are absorbed by extra bracing points on the frame.

The track width can be increased by up to 63cm — even under load. There are two telescopic tubes on either side that act as an axle, with a hydraulic ram to control the track width. The telescopic tubes are actually 90mm chromed piston rods from hydraulic cylinders with 10mm thick walls. Unlike the K2’s predecessor, these axle tubes are now maintenance-free and sealed. The tubes run on brass bushes and use maintenance-free plain bearings that apply a lubricating film to the tubes every time they telescope in and out.

The axle is controlled by a simple lever on the console to the right of the seat. The track width adjustment should only be carried out while the K2 is on the move or when the front wheels are raised off the ground with the help of the loader.

Proving how much of an improvement this makes to stability, when the axle is at its wider track width the tipping load is almost the same at full lock as it is with the machine running straight. This extra stability is even more beneficial if you have the telescopic boom version like we did.

One final point regarding axles. The K2 has an oscillating rear axle rather than pivoting at the chassis.

Telescopic boom

The other telescopic item on the K2TT is the boom, which can extend by up to 90cm. It has also been reinforced compared to the old model.

This extra reach allows the Ostler to achieve a load height of 3.55m at the lower edge of the attachment. Unlike many other handlers of this size/type, the telescopic ram is fitted inside the boom, and it is also the outer 200x200mm section that travels forward. A plastic sliding guide, combined with an anti-stick coating, ensures the boom moves in/out freely. And on the subject of machine maintenance, all of the pivot points have greaseable brass.

A solid looking Euro headstock is standard spec, with hydraulic locking available for €780. An interesting detail is the three pin positions for the Z-linkage on the carriage. This way you can alter the tip/crowd angle to best suit your attachments.

Kubota motor

The K2TT is powered by a four-cylinder, 1.5-litre Kubota that delivers 18.5kW/25hp and is smoother running than a three-cyl motor.

Access to the engine is good: it sits under the rear-hinged seating area that also forms the bonnet. Two steel tanks at the rear each hold around 45 litres of diesel and hydraulic oil.

For drive, a single-stage Poclain hydrostatic transmission transmits the engine power to the wheels, with each wheel driven directly by a hydro-motor rather than a drive shaft. A hydraulic valve block acts as a ‘hydraulic differential’ to compensate for the different wheel speeds when turning a corner, but there’s no lock.

With a max speed of 18km/hr, the machine is not suited for travelling long distances. When you’re on engine revving jobs, then the brake pedal can be used for inching.

Simple design

The user’s workspace is straightforward. The joystick sits directly on the proportional control valve, so it offers direct operation. Auxiliary services are operated via levers on the side console.

The platform itself is a little cramped: foot space is limited, a trade-off for the compact length. On the plus side, the steering column complete with a simple instrument panel impressed us. A lever allows adjustment of both reach and tilt.

A sturdy frame protects the operator. As an option it can swing to the rear, reducing the height to a minimum of 1.90m. We also liked the thick protection bars on the sides. These easily swing up by operating a full-length locking bar, and the guarding stays within the vehicle’s dimensions.

Other details

- Overall, we were impressed with the hose routing — where possible, solid pipes are used.

- An optional rear linkage folds down to a length of 19cm.

- On standard tyres, the machine measures an external width of 1.24m. Our machine was clad with 31×15.50-15 tyres, so the minimum width was 1.40m and 2.00m when the axle was fully extended.

- Optional rear ballast plates are available in 100, 200 or 360kg weights.

- Next year, Ostler is bringing out a larger machine, the K3, which will also benefit from the option of a full cab.

Summary

Heitmann & Wittler is doing a lot of the key fabrication work inhouse, which allows the firm to offer solutions. The business is also on the look out for dealers in other countries.

The Ostler K2TT gave a solid impression. Its chassis is made from 8mm steel, and the only large plastic component is the steering column.

The telescopic front axle makes the loader much more stable and far safer to operate, particularly on models with an extendable boom. This comes at a price: the K2TT costs €42,900 — around €5,700 more than the base version with standard boom and fixed front axle.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.