With a lift height of 3.20 metres and an unloading height of just 2.20 metres when the bucket is fully tipped, these are stats that make the loading of woodchip into a high-sided trailer a challenge … to say the least. That’s why I decided to build a lightweight high-tip bucket for light material that has an unloading height of almost 4.0 metres.

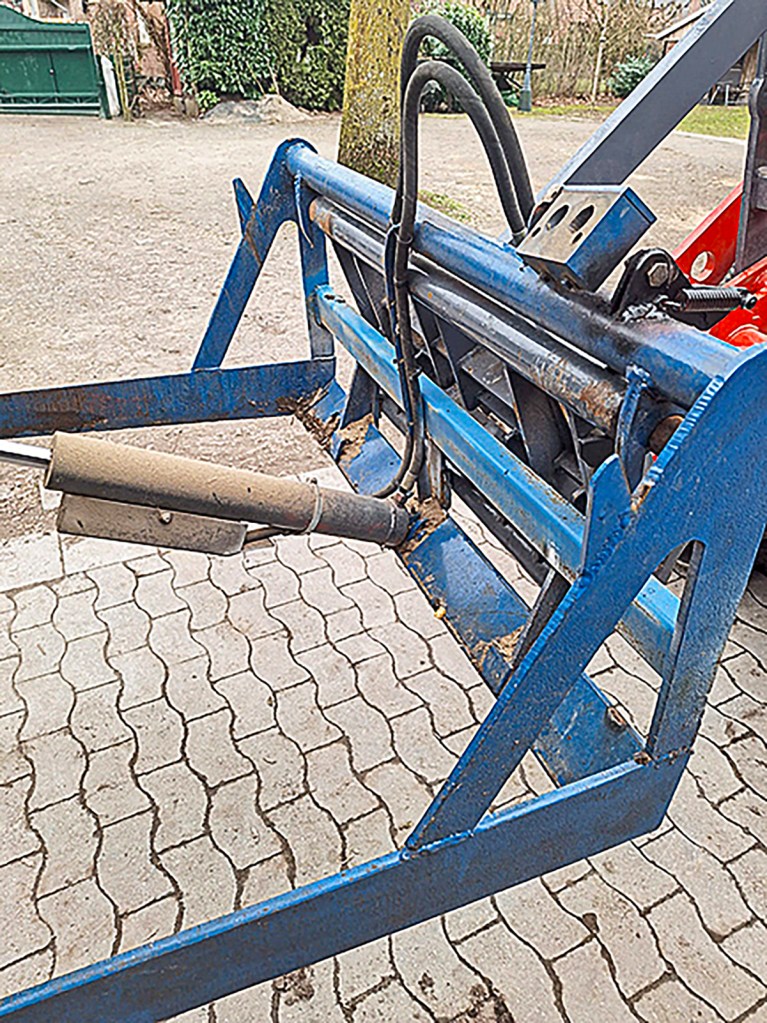

I made the 1.20m wide, 0.80m high and 1.50m deep bucket from 5.0mm thick sheet metal. It boasts a frame of 12mm thick flat steel. I positioned the bucket’s hinge point on the sides near the front. The 50mm pivot pin is greaseable.

The tipping ram is located in the centre of my bucket. I used a wooden mock-up to get the linkage geometry correct. Fitting two rams, one on each side, would have made it far more complicated and would have also made it significantly heavier than its 250kg. The hump in the floor of the bucket that hides the ram doesn’t cause any problems when handling bulky material.

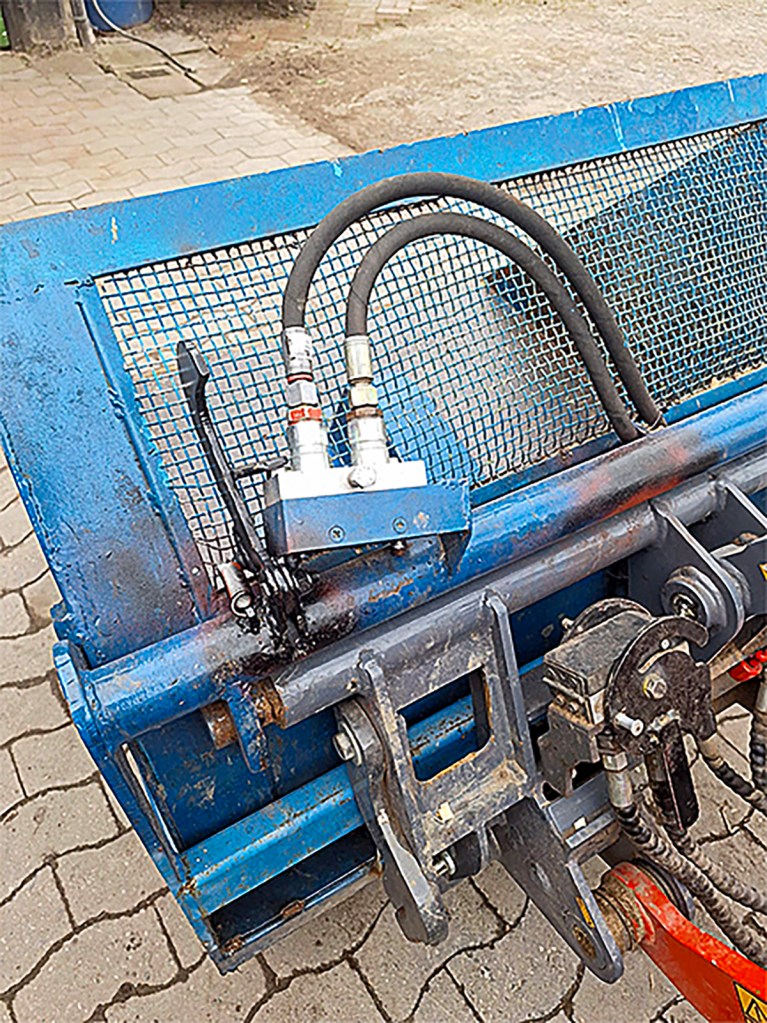

We regularly swap attachments. The loader has a hydraulic quick attach, but the quick-coupler for the loader auxiliary service was occasionally forgotten about. To prevent it getting damaged, I added a hook next to the coupler’s holder. This hook is folded up when the multi-coupler is removed, but, when the coupler is connected, the hook is folded down and latches onto the headstock, so you can’t drive away with the auxiliary hydraulics still connected. In this way, stretching or snapping the hoses is avoided.

For more up-to-date farming news click here and subscribe now to profi and save.