British farmer and contractor A & R Ivatt is the proud owner of the 4,500th self-propelled sugar beet harvester to leave the Holmer factory in Germany. We caught up with the Lincolnshire business to see the start of the lifting campaign.

KEEPING IT BRIEF

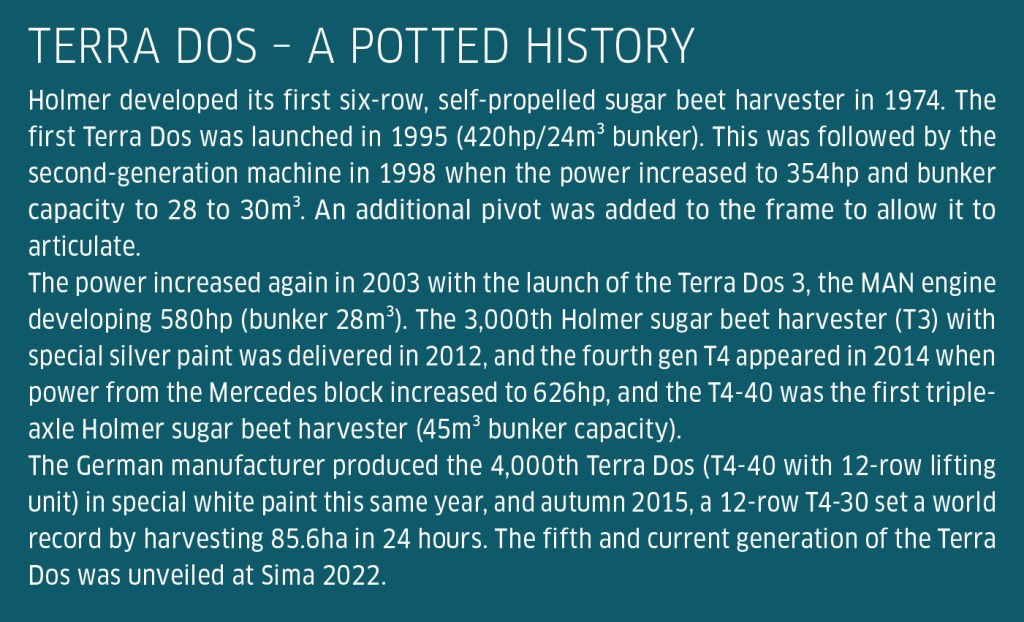

- Holmer Terra Dos 5 launched at Sima 2022

- A & R Ivatt’s machine is the 4,500th Holmer sugar beet harvester

- Power comes from a 652hp Mercedes Benz engine

- The 45m³ capacity bunker unloads in under one minute

- The Terra Dos 5-40 costs from £600,000-£700,000

THE colourful striping along both sides of the machine are not the only eye-catcher as this celebratory Terra Dos 5-40 also has a 4,500 decal at the rear. Supplied by UK importer CC Agri (Chris Coleman Agricultural Engineering), A & R Ivatt’s machine is one of just three 5-40s in the UK and Ireland.

Lifting 1,416ha (3,500 acres) in a season that runs from September to sometime in March, and operating in a 35-40-mile radius of the 550ha family farm near Spalding, the Ivatt family has lifted beet since the early 1970s.

Richard Ivatt who started the contracting business with his father Anthony, has sat on a beet harvester for six to seven months each season since his 16th birthday in 1976. The lengthy list of harvesters he has piloted include a variety of Standen and TIM trailed machines.

His first self-propelled was a Kleine SF10, and while Richard has driven machines from various manufacturers, for the past 16 years he has been loyal to Holmer. The contractor has run three T3s, four T4-30s. The ninth machine is the contractor’s second fifth generation harvester and first six-wheeler.

Terra Dos 5-40

The 45m³ bunker is also the largest, and a significant increase on the 30m³ capacity of Richard’s previous Terra Dos 5-30.

“The capacity of our latest machine is well matched to our 40m³ (approx. 28t) Hawe Ruw 4000 chaser,” he adds.

There are two core models in the latest Terra Dos 5 series, the 45m³ bunker triple-axle 5-40 launched at Sima 2022, and the twin-axle 5-30 (30m³/21t). Both drop the ‘T’ from the series name, and the Ivatt’s roughly £660,000-costing harvester, which was delivered at the start of this season, had lifted 390ha in 315 engine hours at the time of our visit.

The basic design concept is carried over from previous T4-40, and while both harvesters share the same running gear and hydrostatic drive, power from the 15.6-litre Mercedes Benz engine is upped to 652hp. Other updates include more powerful hydraulics and with more than 300 LEDs, the lighting concept has been completely reworked.

Otherwise, the front half of the 5-30 and 5-40 is identical. The main difference is the rear module of the third axle and the longer bunker above it on the 5-40.

In developing the fifth generation of the Terra Dos, the focus for Holmer engineers was to improve operator comfort, reduce operating costs and increase lifting performance in weed infested crops. Suitable for use with six to 12-row harvesting units, Richard confirms that the higher suction generated by the new rounded design of the hood on the integrated HS flail topper boosts performance in crops with lots of tall weeds and better copes with high volumes of dry beet leaves.

He is also full of praise for the larger diameter (850mm) depth wheels next to the oscillating shares. “They are a big improvement,” says the business owner. “The larger footprint prevents the lifting unit from sinking into the soil when its wet.”

Something retained from the previous harvester is EasyLift. This patented technique automatically regulates individual depth of all six shares and flails on every row even when working on deeply rutted land. From here, roots pass across seven cleaning rollers. It was always possible to reverse the direction of the seventh, but the possibility to vary the speed to cope with higher volumes onto the transfer web between the front wheels to the first of the three turbines is new.

The transfer web is also worth mentioning. Richard stresses that the limiting factor with all sugar beet harvesters is how quickly you can get beet between the front wheels. “This is the bottleneck,” he adds. “The 900mm-wide transfer web is ideal and I normally run it at 50% of maximum speed even when working at speeds up to 8.0km/hr.”

Beet on the move

We joined the contractor on two different days. The first time we saw the Terra Dos it filled a 18t capacity Bailey Beeteaper. This was swapped for the triple-axle Hawe chaser for our second visit where Richard was lifting beet at the family farm.

He explains that the trailer is used when beet is tipped into a heap on concrete, whereas the Hawe chaser is good when side emptying beet in a clamp at the headland.

“We can stack it to a height of around 5.0m and by not running on the land below the clamp there are no wheelings for roots to fall into,” he comments. The chaser is also used in the wet when the trailers are required to carry beet on the road. “The trailers never come into the field. This helps to keep mud off the roads.”

Despite its 15m length, the three steerable axles and articulation allow the harvester to turn in an inner radius of just 6.5m. The minimum headland Richard can get away with is 30 rows (five passes), but he prefers eight rounds and 48 rows. “The rest of the field is so much easier with a wider headland.”

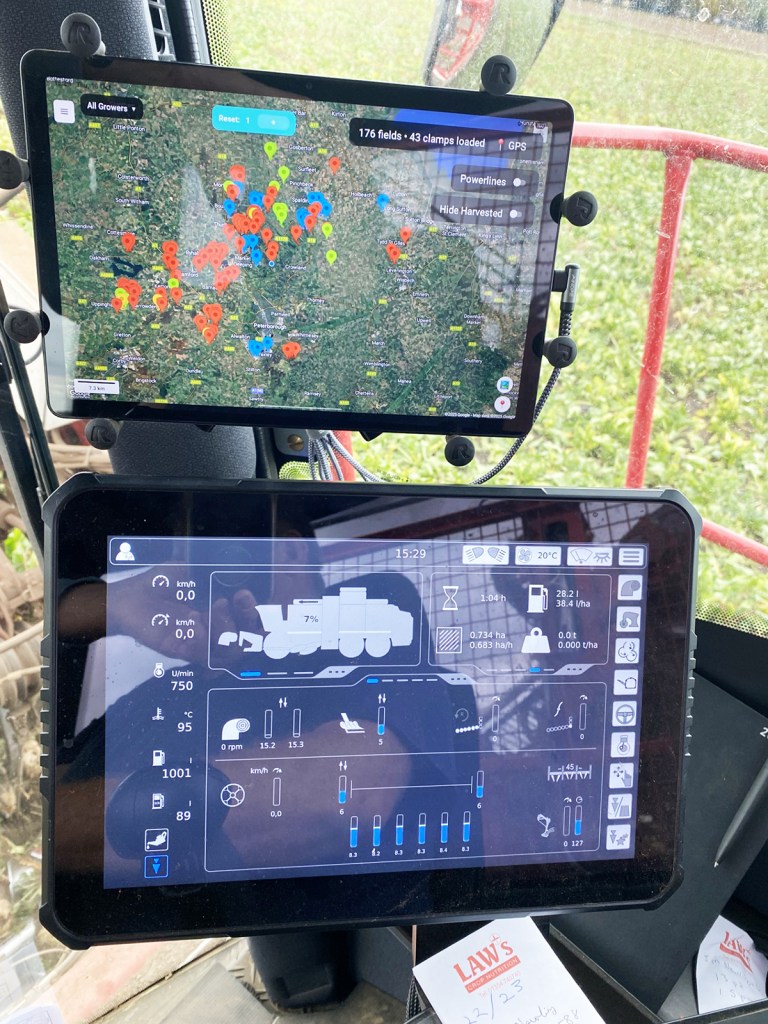

Richard leaves the yard at 7am and tries to head home sometime around 7pm. At the time of our visit, he still had 127 of the total 176 fields to lift, the smallest is under 1ha, the largest 45ha. With the exception of Christmas and Boxing day, Richard and tractor driver Ben Bland will lift beet every day until the end of this year. The first opportunity for a day off will be sometime in January or February.

When this season is finished, Richard will hard face the rollers and give the harvester a good service. “I might need to put in a new set of lifting shares and the scalpers will also need replacing.”

Holmer importer CC Agri provides two years bumper to bumper warranty on a new Terra Dos, plus, an additional drivetrain warranty for the third year. This explains why most machines are part-exchanged after two to three seasons.

A & R Ivatt normally keeps a machine for three years. “We try to stick to this policy,” says Richard. “You pay either in depreciation or repairs, and that the repair bill tends to increase after three years.”

CC Agri tries to keep used machines and overhaul them in the UK. This is hardly surprising considering that it costs around £15,000 to transport a machine to Germany and another £15,000 to bring it back.

Steven Vale

For more up-to-date farming news click here and subscribe now to profi and save.