The VariQtire from IWN is getting closer to the market and is expected to go on sale mid-2026. Unlike other systems which have external hose routing to the tyre valve, this uses a rotator on the inside.

With the wheel removed, the thin metal plate for holding the rotator is fitted to the hub. A hoses then goes between the rotator and the wheel rim. A smart valve removes the pressure in the line when it is not needed helping reduce wear on the seals and allow it to behave like a two line system.

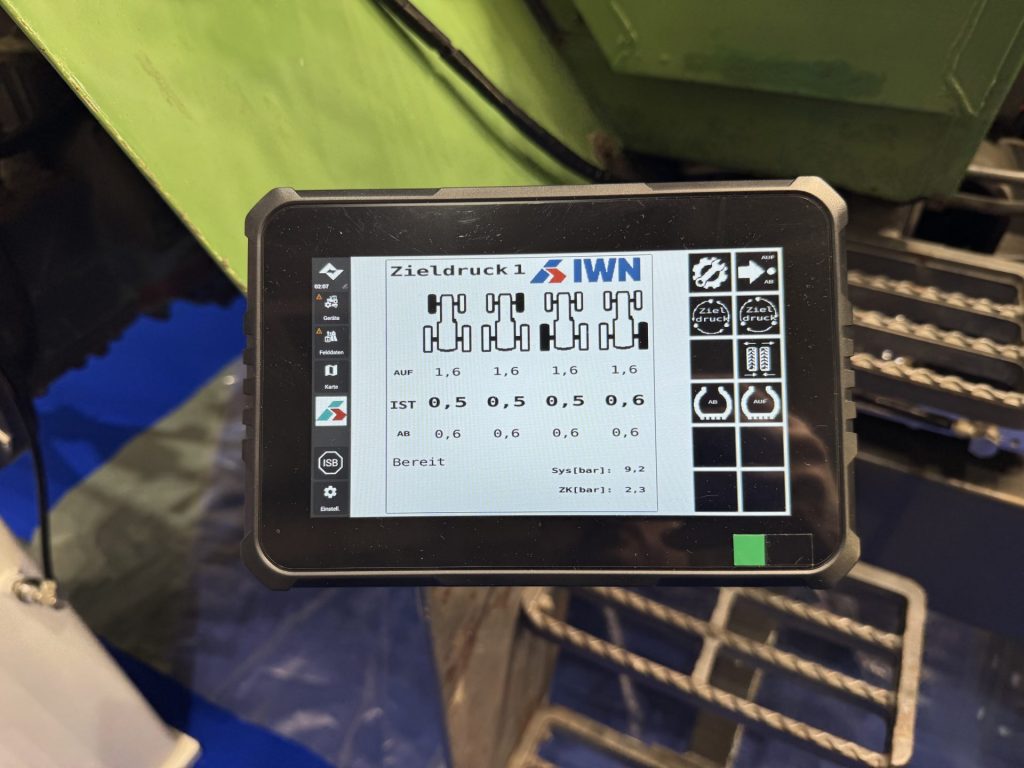

When using the tractor’s air brake compressor, it takes around 10-15 minutes to inflate by 1.0 bar which is done in 0.1bar steps alternating between the four wheels. It takes around two minutes to deflate by the same amount.

An advantage of this design according to Christoph Schulte from IWN is that you can easily change wheels sizes as the hub is not affected, just refit the hose. A radar sensor on a separate wheel valve also keep an eye on the current pressure in case of over or under inflation. The system can be worked from its own terminal or connected to the tractor’s ISObus. A shot of grease every 50-70 hours keeps the seals clear of grit.

IWN is not only looking at the retrofit market, it is also in discussions with vehicle makers as an OEM supplier.

We had an earlier look at this system in the 09/2023 issue which can be found here.

For more up-to-date farming news click here and subscribe now to profi and save.