Since their launch in 2015, the Case IH Optum and New Holland T7 HD have settled-in to become a strong presence in the increasingly popular 250 to 300hp sector. The packages were good when introduced and still have plenty to offer, especially now that early niggles have been ironed-out and fine-tuned with more recent updates.

The Case IH Optum and New Holland T7 HD (heavy duty) are based on the same common platform, which is also shared with the Terrus range from the fellow CNH Industrial manufacturer Steyr. Indeed, around 90% of all three tractors is the same, with the main differences found inside the cab especially when it comes to the controls. The blue and red versions have sold fairly well in the UK, with their arrival being well-timed to cash in on the phenomenon of the jack of all trades mid-weight, high-horsepower tractor. But export demand has helped to reduce the UK herd, meaning that although used buys are about, they are potentially less plentiful than you might expect.

When launched at Agritechnica 2015, the New Holland T7 HD bridged the gap between the T7 LWB and T8 Genesis, whilst in the red corner the Case IH Optum nestled snugly between the Puma and Magnum. In both ranges the existing smaller models (T7 LWB and Puma) had an 8.5t kerb weight and maximum power of 270hp, whilst the larger (T8 and Magnum) started at 250hp but tipped the scales at 12t. The new tractors filled the gap nicely, going head-to-head with Deere’s 7R and Fendt’s 800 Vario.

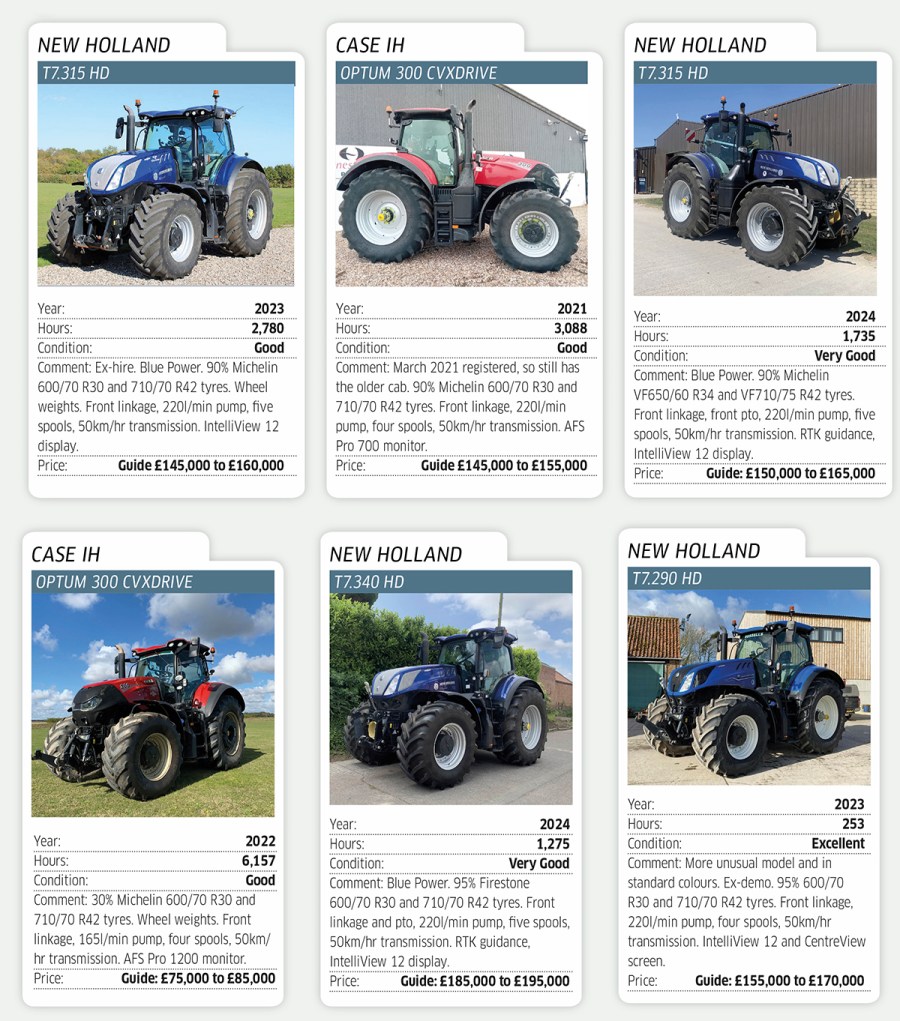

There were two models of each to start with, one rated at 270hp with a maximum output of 290hp, and the other 300hp and maxing out close to 315hp. In a departure from the norm for CNH there was no boost function, both offered full power all of the time. The red ones used the rated output for the model numbers, 270 CVX and 300 CVX, so what you see is what you get, whilst the blue camp opted for maximum power, becoming the T7.290 HD and T7.315 HD accordingly.

Compared to the smaller Puma/T7 LWB, the new developments incorporated some important uprated components and features, including a new chassis with an approximately 10cm longer wheelbase.

The ranges were then expanded by the addition of a lower powered model (rated 250hp/max 275hp) which became the T7.275 HD and Optum 250. These were produced up until the introduction of the 260hp Puma 260 and T7.300 and are very scarce in the UK and Ireland.

It is no secret that some early Optum/T7 HD did suffer from issues, notably transmission and electrical related in particular, but efforts to fix these by supplying dealers followed by upgrades and a product improvement programme introduced in summer 2019 addressed these targeting both new tractors and those already out in the field. So, whilst this may rekindle painful memories for some original owners, the good news is that used buys should all have been sorted out by the manufacturer at the time.

Major revamp

In summer 2021 the tractors had a major revamp. The biggest change was to the cab which was made roomier and contained updated controls and technology. There were other changes, which are covered in more detail in the relevant sections, and a post-update tractor, dubbed PLMi or AFS Connect in blue or red, is well worth looking for. An easy way to spot a new or old cab from a distance is the position of the beacons – an old cab has them mounted at the back, a new cab at the front.

Until the new cab arrived the New Holland T7 HD had been made on its own separate dedicated production line at Basildon, along with any Case Optums destined for the US, whilst UK-market Optums were made at St Valentin in Austria. But this now changed, with updated tractors all produced at St Valentin.

Summer 2023 saw a new 340hp flagship model added which was dubbed the T7.340 HD PLMi and Optum 340 AFS Connect in their respective brand. Baler mode, which matches forward speed to pto load, was also introduced as an option.

So, do you actually need an Optum or T7 HD? The more recently introduced Puma 260 and T7.300 have been really popular and offer compact versatile options which are almost as capable, boosting to 300hp. But those looking for weight and slightly more power, continue reading here.

Front axle and brakes

Beginning at the front. The front axle is different to the smaller models (Puma and T7 LWB) and is taken from the entry T8/Magnum models. Internally known as a class 4.75 axle, it is a ‘saddle’ suspension unit with a maximum load of 7.5t. Under the 2019 improvements it gained reinforced accumulator brackets and a new raise/lower manifold design.

It’s worth a general check over with common sense. Knocking from the front axle can indicate free-play in the front-axle carrier which can be caused by loose or broken thrust washer retaining screw holes. Also check the front axle pivot bushings and the stabilisation arms for wear.

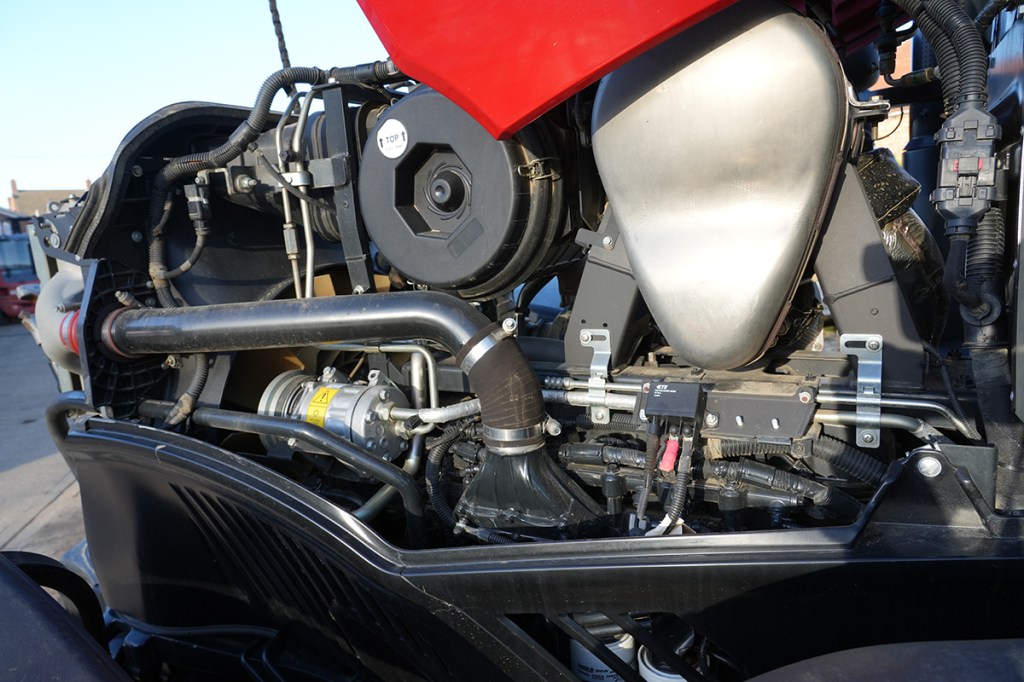

Engine

The engine is the same 6.7-litre FPT used in the smaller models but with a redesigned cylinder head and other uprated components to deal with the higher power output, plus a variable geometry turbo. The sump is also load-bearing, forming the backbone of the tractor in place of chassis rails used by the smaller models. As already mentioned, there is no boost function, which keeps things simple – the power claimed is the power delivered.

Emissions regs are met using SCR and DOC, there’s no EGR in these tractors. Earlier examples met Stage IV emissions regs, with Stage V compliant versions introduced in 2019. At the same time the engine oil (15 litres) change interval was increased from an already respectable 600 hours to 750 hours.

Engine upgrades specific to the T7.340 HD PLMi and Optum 340 AFS Connect included cylinder head improvements, beefed-up pistons and a larger capacity cooling pack, so there is more to it than just a remap to send in more diesel. The extra cooling could be desirable for stationary tasks such as wood chipping where the smaller models can overheat if worked hard.

Engines are generally regarded as extremely reliable. Early tractors could suffer with leaks from AdBlue hoses and oil around the air compressor, but these were addressed under the aforementioned improvements.

Transmission

There was only one transmission option for the T7HD/Optum: the CNH stepless unit with four forward ranges and two reverse which are selected and changed automatically.

On blue tractors it was christened AutoCommand, whilst the red camp referred to it as CVX, and later CVXDrive. The main difference between the two is how the transmission is controlled – New Holland uses a joystick whilst Case IH uses its MultiController lever.

Transmission and hydraulic oil (148l) change interval was 1,200 hours, rising to 1,500 hours when updated Stage V tractors were introduced in 2019, a useful saving given the cost of oil and something to bear in mind when comparing tractors. Another update was made during 2021 which included altered gear profiles and transmission castings to reduce noise levels. Finally, numerous transmission components were uprated for the 340hp models when introduced.

A very early issue with the transmission management not reacting quickly enough to rapidly increased load was fixed with a software update from mid-2016, so also shouldn’t be an issue unless the tractor didn’t get the upgrade. This is a good time to reiterate just how important software upgrades are, not just with these tractors but in general, and why it can pay to deal with a main dealer.

In early transmissions there were issues with internal oil supply pipes for the hydrostatic element and the park brake, but both were sorted out as part of the 2019 updates. There were also some software issues related to error codes and other glitches which were also remedied at the same time, and revised hydraulic filters were introduced.

It’s important to point out that these problems were rectified and are being highlighted for information only. With that aside, going forward transmission issues are rare and appear to be the exception rather than the rule.

Cab and controls

The cab has evolved more than any other part of the tractor during the past decade and if you only take notice of one section then it should be this one.

The original cab, the same unit as used by contemporary T7 and Puma, was good but slightly cramped, with a noticeable lack of room behind the seat.

Interiors were different in the New Holland and Case IH versions, with variation in control layout, information display and cosmetics. For example, the Optum had an A-post display and nothing behind the steering wheel, whereas the New Holland had a dash panel display in the usual place. The Optum also boasted its distinctive red leather-covered Grammer seat as an option, and there were also slight differences in lighting packages. Both setups are good, so personal preference will be the deciding factor here.

The cab received a major revamp in mid-2021. Although the new unit, christened Horizon Ultra on the NH, didn’t look much different from the outside, its size was increased by 7.5%. This was achieved by shifting the rear posts and fenders back slightly and widening and lowering the wheel arches which made room for a wider door and greater glass area, as well as, perhaps most importantly, more room behind the seat. It’s also quieter with more storage areas.

There were also changes to the tech and controls. On the NH the new Sidewinder armrest and IntelliView 12 display were inherited from the T8 Genesis. The conventional dash screen could also be replaced by an optional CentreView screen mounted on the front of the steering wheel – something of a marmite choice. The Optum gained the new Multicontroller armrest and AFS Pro 1200 monitor from the Magnum, and it retained an A-pillar display which was enlarged. Improvements were also made to the cab suspension, seats, climate control and electronic architecture, and more precision farming features were offered.

With the advent of the 340hp models in 2023 a semi-active hydraulic cab suspension option was added to complement the standard spring and damper system. Speaking of suspension, a broken tie rod bushing block can cause the cab to move excessively but can be replaced with an upgraded part.

Given the scale of these improvements, it’s obvious that a post 2021 cab update tractor is desirable and this should be an important consideration when comparing what’s available. Although of course it’s all relative – the original unit was a good cab too.

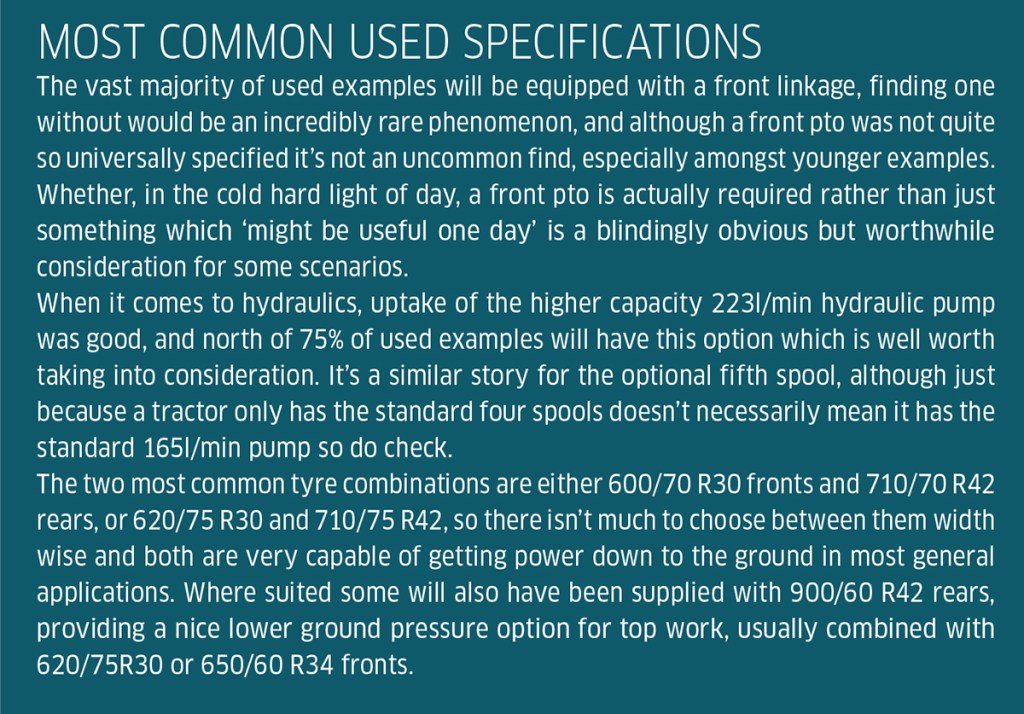

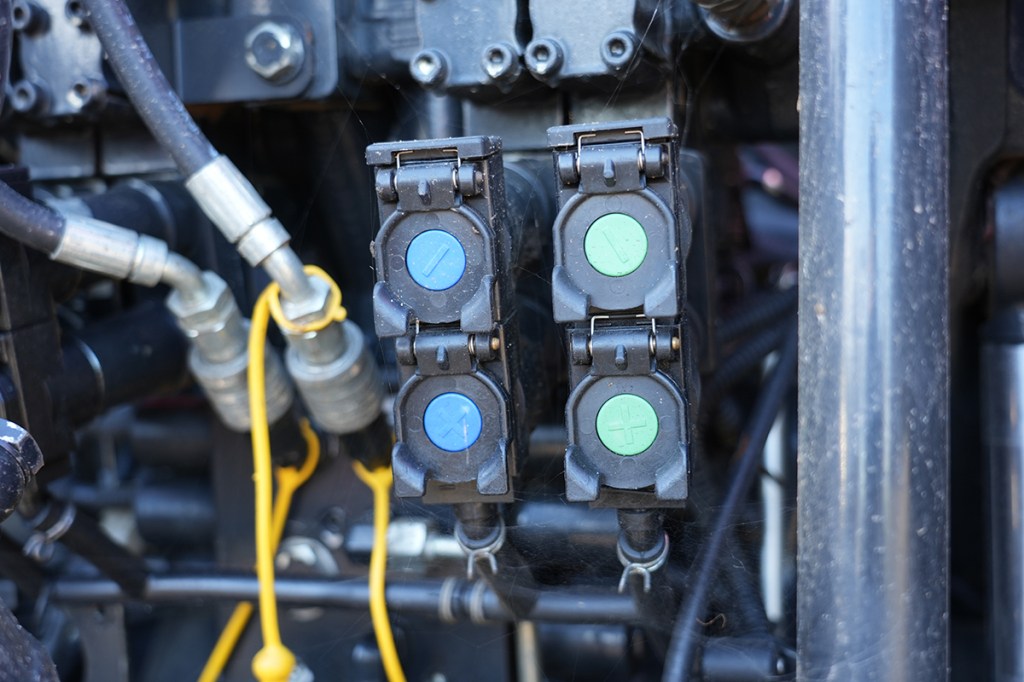

Hydraulics, linkages and pto

Right from day one the hydraulic system of the T7HD/Optum was very capable, with a 165l/min swash plate pump provided as standard with a 223l/min option which was not available for the 250hp models. Most units were ordered with the higher capacity pump. Up to five double acting spools (four were standard) plus a power beyond coupling could be specified at the rear and three spools at the front. The 2021 updates included new rear spool valves, with pressure relief levers, which can be configured to a chosen armrest switch.

Rear linkage lift capacity is also good, rated at 11t, so there’s nothing to worry about in this area when looking at an early example. The front linkage, where fitted, is an integrated unit with a decent capacity of nearly 6.0t.

The pto spec was also well up there, with a four speed (540/540E/1000/1000E) at the rear selected by a switch being particularly respectable in this class when the tractors were launched. The front pto, where fitted, is a two-speed 1000/1000E unit.

Other than the obvious things, useful options to look out for include a hydraulic top link, which wasn’t standard, and the optional factory-fitted hydraulic stabilisers.

Running gear

Brakes are not a known weak area, performing their task as required.

When it comes to rubber, the T7HD/Optum could accommodate taller tyres than its siblings – the new platform was designed to take a 2.15m tall tyre which translates into a 710/75 R42. The optional tyre pressure monitoring system displays pressures in the cab using TireMoni valves. A bar axle could be specified, and most buyers did tick this box so used tractors are most likely to have one.

General points and summary

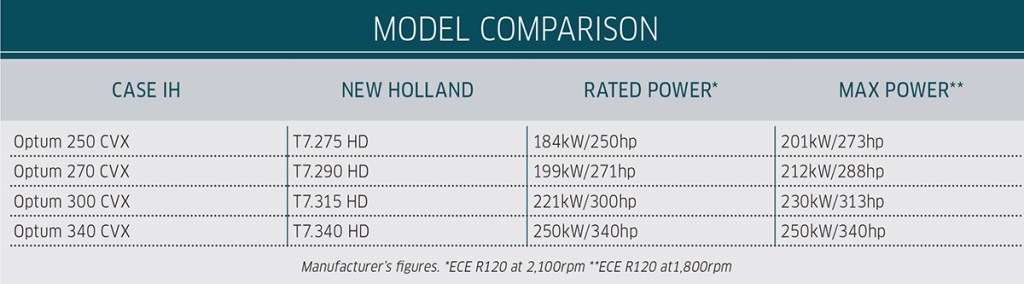

There is no denying that a used T7 HD or Optum can represent a good package and a sensible purchase. Performance is good, with low fuel consumption, good hydraulic output and lift capacity, and they are generally well-liked by operators. Reliability and running costs are in-lieu with the competition. In these respects, the design has withstood the test of time, especially with the timely updates factored in.

The choice between blue or red isn’t an argument for this feature, they’re both good tractors and the local dealer, brand loyalty and a preference for one control setup or the other will ultimately be the deciding factors.

The Blue Power pack for New Holland models, consisting of a deep metallic blue (‘Maserati blue’) paint with silver wheels, a leather clad steering wheel and Blue Power embroidered seats, special floor mat and additional lights, cost an extra £5,000 when the tractors were launched. Uptake was strong, and still is, so much so that seeing a standard tractor is slightly unusual. This preference also carries through to the used market, with Blue Power tractors more desirable and selling faster.

Basic technical specification has always been good, and most tractors in this power class will have been frontline machines with options like front linkages the norm rather than exception. Of course, there are far too many options to cover in detail here, and fully checking what a tractor does or doesn’t have is made easier when purchasing from a main dealer.

Other routine considerations include tech, as most will have been used with some sort of guidance system. Again, this decision may also be influenced by what is already being used on-farm, as it might be easier to make the new addition conform rather than introduce an unfamiliar setup into the mix.

At the younger end of the scale, popularity in the arable districts of the UK means that ex-demo and ex-hire examples can become available from dealers in these areas, such as Ernest Doe & Sons and Russells, offering a sensible saving on new price with relatively modest hours. These will usually have some of the three year or 3,000-hour warranty remaining which is also well worth having.

Earlier examples with north of 5,000 hours tend to make from £60,000 to £80,000 depending on spec. Younger tractors with less work under their belts tend to hover each side of the £150,000 mark, whilst nearly-new ex-hire and ex-demo tractors are usually priced closer to £190,000. Used examples don’t tend to hang about for too long, and auctions don’t necessarily mean a cheap buy either, as healthy demand keeps prices up.

With grateful thanks to Matt Hart, Ernest Doe & Sons, Ulting, Essex, Jack Arnold, Ernest Doe Power, Fakenham, Norfolk, Andrew Collier, T H White, Marlborough, Wilts, Cormac Duggan, Cooney Furlong, Co Wexford, Philip Maw, Russells, Old Malton, North Yorkshire, Farmstar, Marr, South Yorkshire and Darragh Mullin, CNH.

Chris Lockwood

For more up-to-date farming news click here and subscribe now to profi and save.