For many years, Thomas Cappellaro played a key role in transmission development at ZF. Now retired, he still helps out as and when required.

KEEPING IT BRIEF

- Thomas Cappellaro co-developed the first electronic transmission control system.

- He tested every vehicle himself that carried components he developed.

- His first boss and mentor was Friedrich Scheiber.

- Today, Thomas helps out on refurbishing his initial designs.

“Back then, mechanical engineers were afraid of electricity,” says the former ZF design engineer, as he describes the atmosphere in the 1980s. Born in 1959, he studied precision engineering in Munich, a blend of mechanical and electrical engineering now known as mechatronics. After starting out on his career at Webasto, he moved to ZF in Passau in 1985.

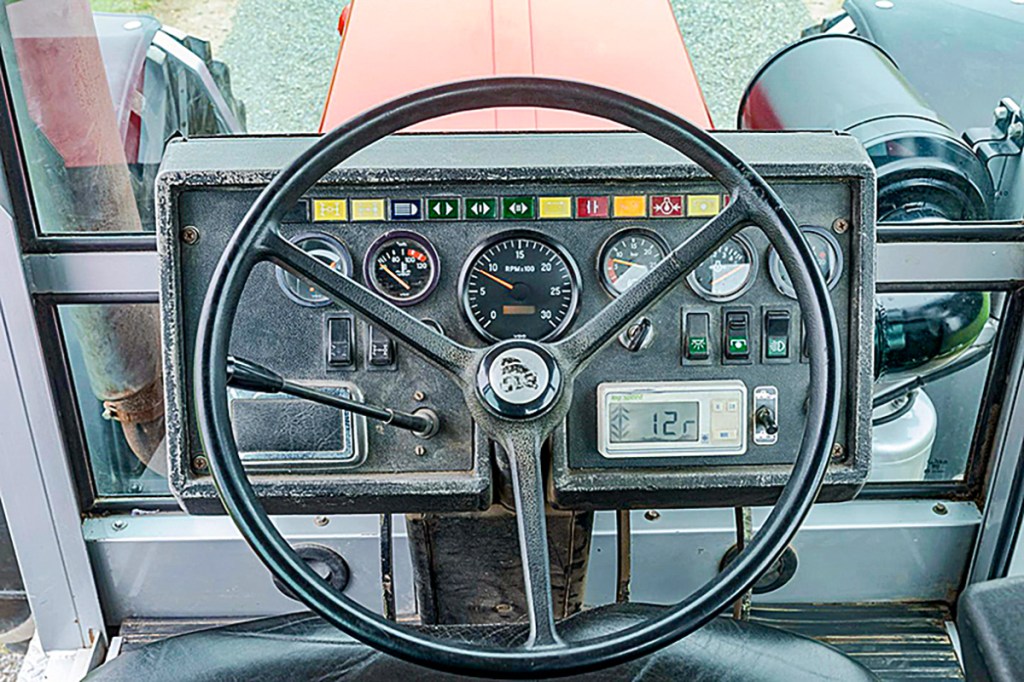

A Passau native, he found his career calling in ZF’s experimental department — electro-hydraulic control systems for powershift and continuously variable transmissions in construction and agricultural machinery. He oversaw these projects from conception to functioning prototypes, one of which was the full powershift Schlüter Super Tronic 2200 TVL or the stepless Super 1900 TVL. However, Schlüter was far from Thomas’s only client, as he worked on other tractor and self-propelled machinery projects with other manufacturers.

Into the nitty gritty of a gearbox

He was one of the first developers to log into a tractor transmission with a laptop. After playing a pioneering role in introducing electronics to the world of transmissions, he became head of ZF’s axle testing department in 1989. This position involved developing four- wheel-drive axles with suspension for tractors and also road vehicles.

After seven years in axle development, he returned in 1996 as a group leader to his favourite field of work: transmissions. Under his leadership, the ZF T7000 gearbox with its six ranges and four and six powershift steps was created. This was used by Deutz-Fahr, Fendt and Steyr.

Thomas Cappellaro and his team placed a particular emphasis on powershuttle boxes. In 2001, he became head of R&D and testing of mechanical gearboxes and rear axles.

From 2018 until his well earned retirement in 2022, he was Senior R&D Manager for drive systems on mobile working equipment and electrical, hydraulic and mechanical components for mobile working equipment systems.

Worldwide traveller

During his time at ZF, Thomas collaborated with almost every tractor manufacturer in the world and drove every machine that used one of his developments. An important aspect was working alongside engine makers to integrate the transmission into the overall powertrain.

A particular achievement for Thomas was his early understanding of the mechanical limitations of a gearbox which can only be overcome with electronics. It was he and his colleagues that not only ensured ZF was competitive in a challenging market, but also helped transform it into becoming a major player in the industry.

Thomas Cappellaro is still grateful today for the trust placed in him by his first boss, test manager Friedrich Scheiber, and the support of his colleagues at the ZF sites in Passau and Friedrichshafen on Lake Konstanz. He says these are the people who provided him with the necessary tools and taught him the skills he needed to develop transmissions, to the point that he was widely referred to as Mr Powershift.

Helper for special projects

The transmission expert doesn’t know how many tractor and other machines have been built with his inventions and developments that are still running today. Over the years, however, he has built up a private archive and has already helped out many owners of vintage vehicles or workshops by providing drawings, part numbers and settings. Even in his retirement, he still enjoys doing this, although the feedback rate could be higher. Still, he wouldn’t have become Mr Powershift, if he’d been reliant on receiving external thanks and recognition.

Wilfried Holtmann, Maria Henkemeier

For more up-to-date farming news click here and subscribe now to profi and save.