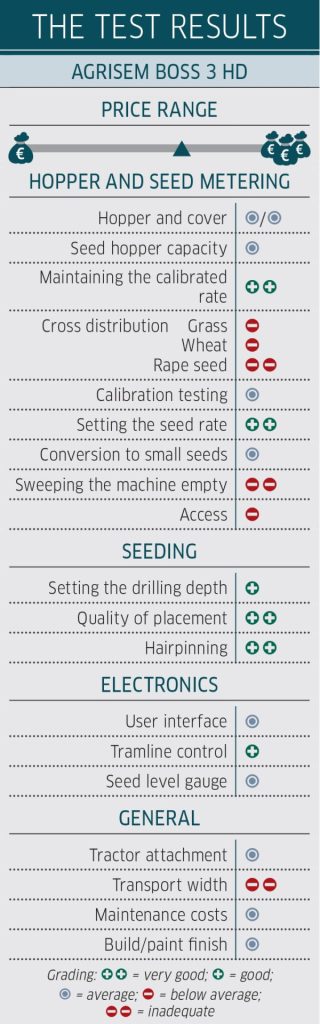

A boss is expected to have leadership qualities. Our test candidate showed it excelled in some areas, yet there was still work to do in others.

KEEPING IT BRIEF

- Although primarily designed for no-till drilling, the Boss can, to a limited extent, sow into min-till prepped land.

- For the most part, it worked well.

- There is still room for improvement to the metering unit, calibration, distribution across the rows and the seed hoses.

Agrisem’s Boss 3 HD 18.75 model is a classic direct seed drill with individual depth-controlled and angled single-disc coulters. Our test subject is the smallest of the trailed models that utilises the same Boss coulter system for machines up to 12m wide. The French firm also has a fully-mounted toolbar (3.0m to 9.0m) which can be used with a front hopper.

Back to our test and getting hitched up. It uses a Cat III lower link crossbar, but, when it didn’t marry up with our lift arm settings, we got the measuring tape out and found it was slightly wider than it should be. This minor design issue has now been fixed, and the headstock does still let you make tight, 90⁰ turns.

Three double-acting spools are needed for the drill’s running gear, raising/lowering the coulters and transport wheels, and a single-acting spool with a return line is used for the fan. All four services can be accessed and shut-off on the drawbar — the durability of the identifying decals needs improving, though. That just leaves the ISObus and road lights to be plugged in. The folddown parking stand under the drawbar scores for its large ground plate.

With undercut

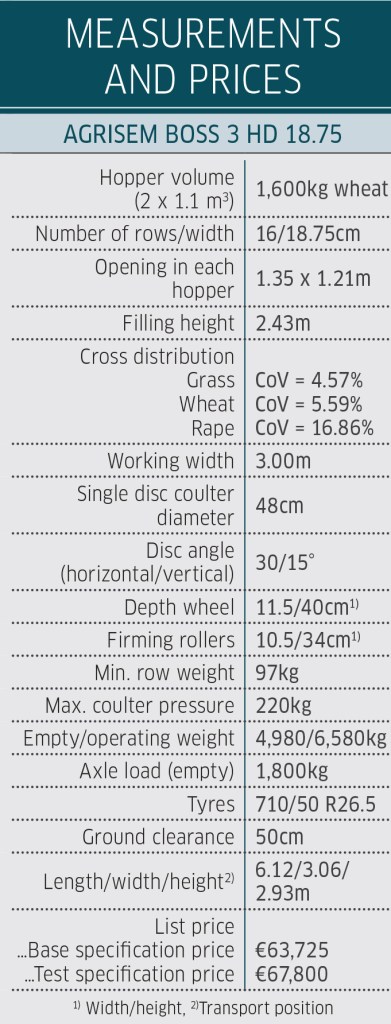

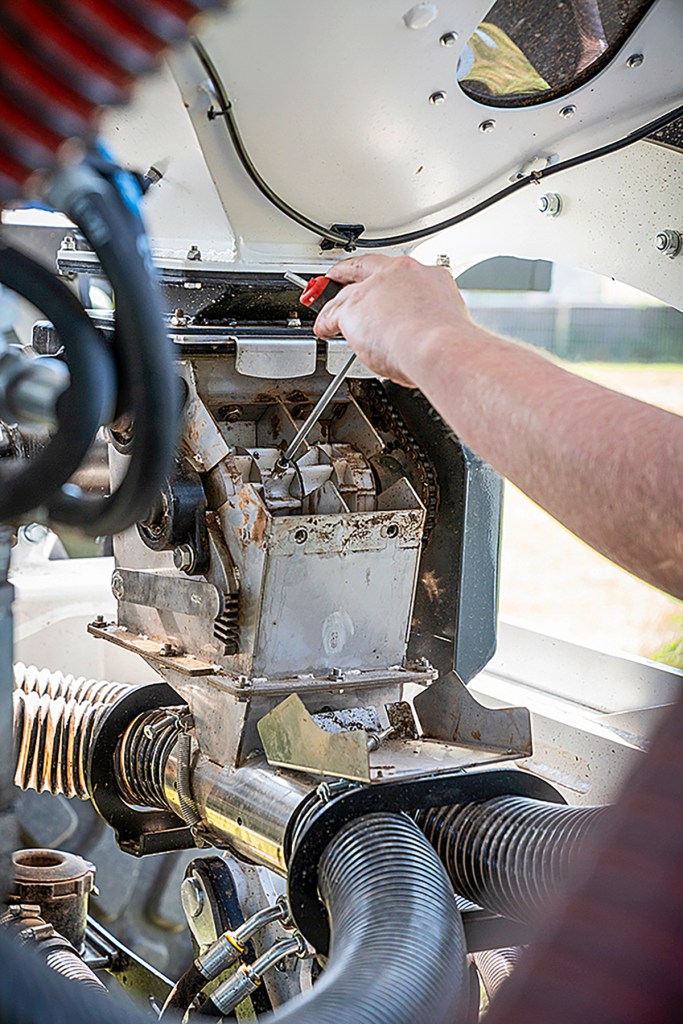

The drill’s 460mm diameter disc coulters are angled in two planes — 30° in the direction of travel, 15° laterally — helping to ensure reliable penetration without relying on high coulter pressures for a constant working depth. Both of these features help reduce the power requirement and soil compaction. Speaking of fuel, we were able to effortlessly pull the 3.0m wide, 16-row Boss drill with a 160hp tractor, which sipped its way through two to three litres of diesel per hectare — proving one of the advantages of a direct drill system.

In the shadow of the disc is a tight-fitting seed boot, which places the seed in the soil. A press wheel then closes the furrow and precisely governs the depth of the seed boot. There are three types of press/closing wheel available; we had good results with the standard wheel on our medium to heavy soils.

The press wheel can be adjusted without tools to one of five angles and 19 sowing depths. Access to each coulter unit is pretty good, with even those units in the middle of the machine making these key adjustments relatively easy. We were able to achieve all the desired sowing depths for a range of crops from oilseed rape to beans. However, by the end of the season, the bearings in six of the press wheels were failing. Agrisem says this was a supplier issue that has since been resolved.

Running alongside each disc coulter is a gauge wheel which, as well as acting as a scraper to keep the disc running clean, also prevents it from sinking too deep in light soils.

Each coulter has its own sturdy parallelogram linkage with 15cm of vertical movement for contour following and weighs 97kg before being pressurised. They are hydraulically raised/lowered and also apply the downforce — Agrisem refers to this as holding pressure — from a shared circuit. The pressure is adjusted from a manually operated throttle and gauge on the drawbar. We measured a maximum of 220kg at 40 bar, although we never actually needed this much downforce in the field during the test. Even at lower pressures, penetration was never an issue.

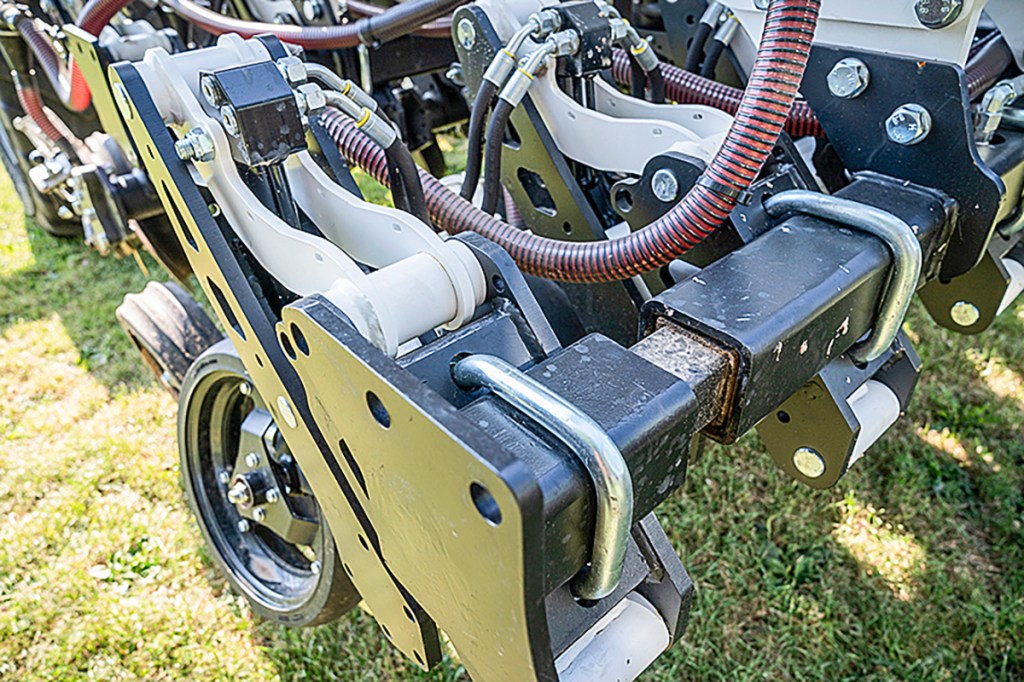

Pitfalls in calibration testing

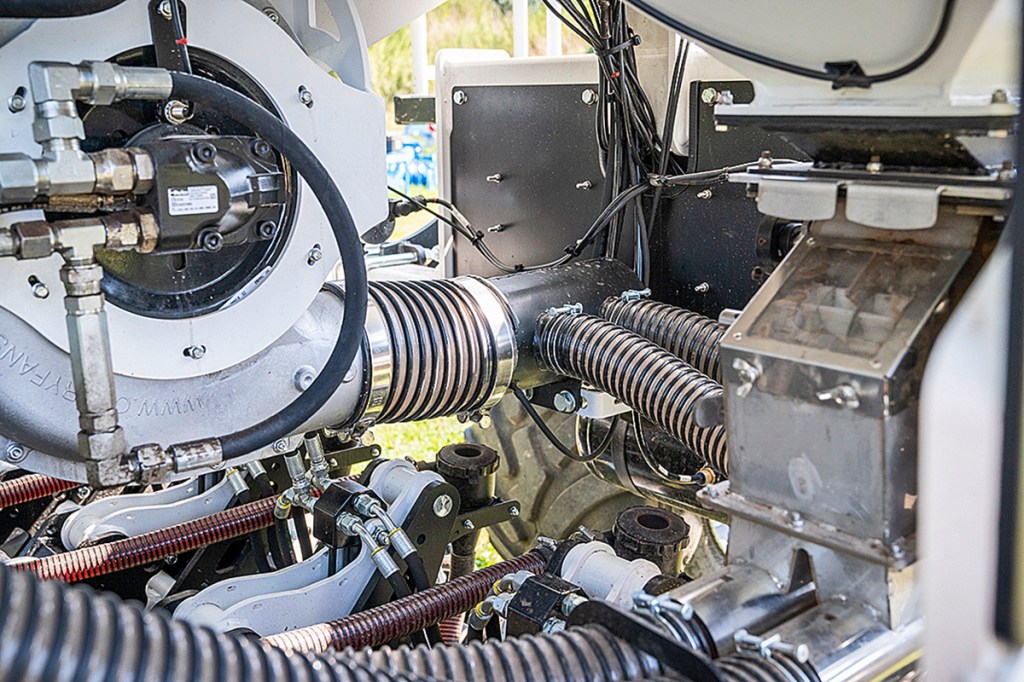

Both metering units are equipped with eight cell wheels, four for each distribution pipe. Depending on the seed quantity and size, you will have to fit or remove individual wheels, which are held in place with various Allen screws (tools are not supplied with the machine). It is not the easiest operation, particularly with the smaller wheels. There is definitely room for improvement here.

The cell wheels are driven electrically via a chain; we can’t understand why they don’t just power it directly without the chain. It would be nice if the agitator shafts on both sides could also be switched off.

Nevertheless, the seed flow to each half of a metering wheel can be shut off with a slide. We would have preferred a more convenient way of adjusting the bottom flaps. Unfortunately, there is no mechanical means of emptying tank leftovers.

Choice of delivery lines

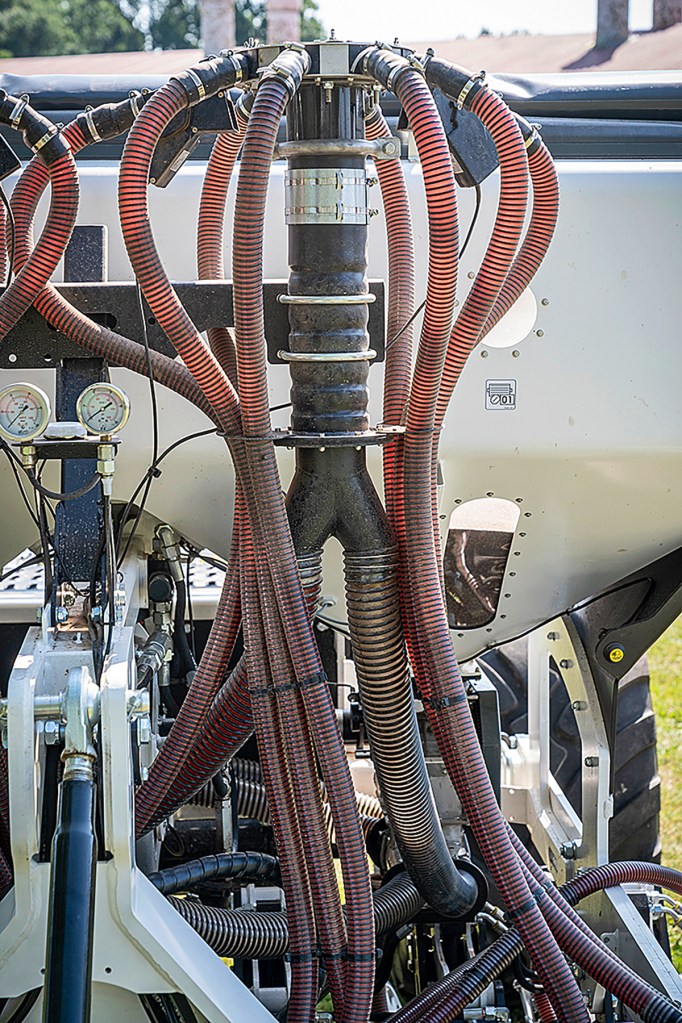

As mentioned, there are four delivery pipes in total. That’s two for each half of the split hopper, with one of these supplying the left distributor head, the other the right. Other configurations are possible for either single- or double-shot placement of different seed/material.

A relatively high fan speed of 4,500rpm is needed for the pneumatic system. A cyclone separator is positioned above each seed boot to vent overpressure. A minor downside to this arrangement is the relatively long time that it takes the seed to reach the soil — something to bear in mind on ins and outs or if you are using section control.

The seed boot has two inlets, one for small and one for large seed. Selecting the correct outlet is done by switching the seed tubes, which is a pretty cumbersome task, even on our 16-coulter drill.

High rates are an issue

When sowing rates exceed 250kg/ha, like with beans, the system is prone to blockages when using only one metering unit. In these scenarios, a perforated section in the riser pipe is supposed to be opened but, in our experience, seemed to make little difference. A new lid for the distributor head is reckoned to solve the issue, but we don’t know if this will benefit distribution across rows.

Seed rate tops, calibration flops

To calibrate, you first select the product and the seed rate on the ISObus terminal, prime the metering unit and then start calibration testing by pressing a little button under the hopper. So far, so good.

We were less impressed with the calibration trays that are stored on the walkway, and the holders under the metering units are also not practical. We found using 5-litre buckets for collecting the seeds worked much better.

With the calibration done, don’t forget to close the flaps, as there is no alarm to remind you. Speaking of forgetting, there is also no provision for hanging the calibration scales. On the plus side, the drill is accurate: the maximum deviation was 1.0%.

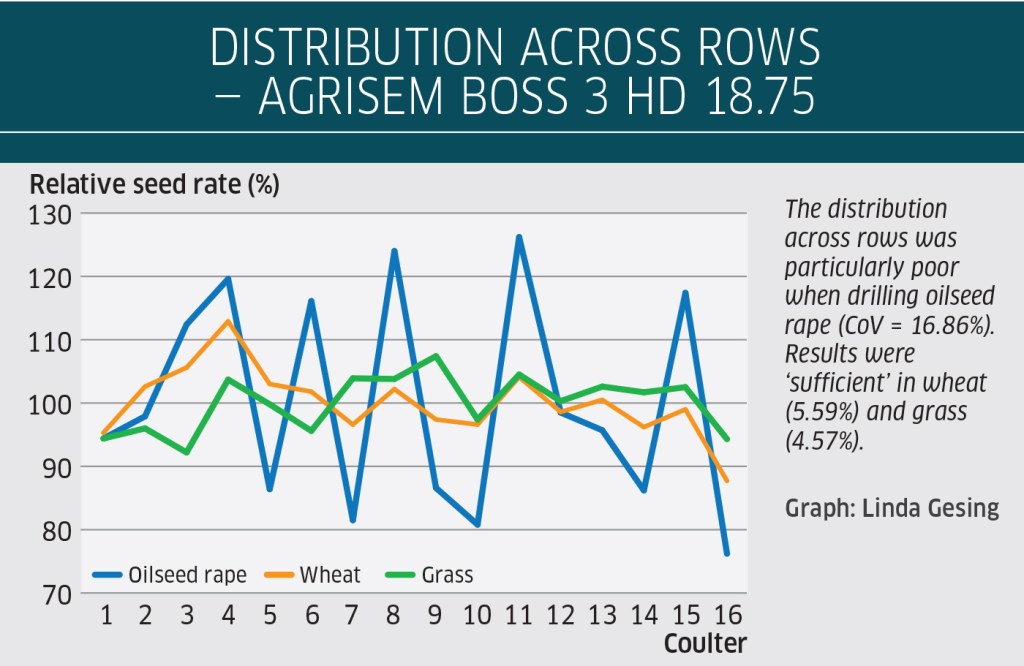

Cross-distribution — not good

The Boss drill should have performed much better in our distribution across rows test measurements. While the coefficients of variation for both wheat (5.59%) and grass (4.57%) are still considered adequate, the values for rapeseed (16.86%) were outside of the target. In fact, with some individual coulters, the rate was up to 40% off.

Two 1,100-litre hoppers

Our test machine had two hoppers, each rated at 1,100 litres capacity. We filled each with about 800kg of wheat, which is a bit tight. Agrisem also offers 1,600-litre double hoppers if you need more capacity. A sturdy tarp covers the opening, and the loading height of 2.43m is fine, too.

For those wanting to load directly with a loader bucket, the 1.35m wide, 1.21m deep hopper opening will pose a problem. If you want to fill up both hoppers with the same seed, some seed will inevitably spill outside as it bounces off the tarp cover’s support bars.

Another point of criticism is the fact that the screens are low down in the hoppers. Not only does this make them difficult to reach, but each one is secured by four screws, which you will have to remove if you want to adjust the height-adjustable seed level sensors — very inconvenient. The other level sensor is fixed and located higher up. On the practical side, there are windows in the lower third of the hopper so you can see the amount left from the tractor seat.

The walkway that runs across the back of the machine is reached by a three-step fold down ladder. The first step is 62cm off the ground so it’s a bit of a stretch, especially when the machine is raised for calibration testing, for example. And the ladder locking mechanism could be smoother, too.

Regardless, Agrisem needs to change the overall design, because even with the ladder stowed away, the Boss is 3.06m wide on the road. Yes, it may be only 60mm, but that’s still outside the allowable 3.00m limit.

Our machine was fitted with a pair of €2,155 optional Alliance 710/50 R26.5 tyres. Larger tyre sizes are not available for this working width. Standard wheel size is a rather mean 500/45 R22.5. The drill can be aligned at the rear using spacers on the chassis cylinders and at the front via a top link. It is a set-up that works well. At the headland only the lift arms and the coulters are raised.

Field experience

We typically worked between 7 and 9km/hr using the Boss to drill both direct and into min-tilled ground. The latter worked quite well on heavy soils, whereas on sandy soils there was often not enough resistance.

Direct drilling after cereals, rapeseed or beans is where the Agrisem really shines, where it’s in its element. Generally speaking, hair-pinning was virtually non-existent.

The Boss system works best when running at a slight angle to the previous direction of drilling.

Other details

- The empty Boss weighs 4,980kg, 3,180kg of which rest on the axle. It can be filled with 2,520kg of seed for road transport at up to 40km/hr.

- ISObus operation is fine.

- A storage compartment for accessories would be helpful.

- The basic version of the Boss 3 HD 18.75 costs €63,725, while the test version lists at €67,800.

Summary

The Agrisem Boss 3 HD 18.75 is a true direct drill. After sowing, you can hardly see where it has been, and, of course, there are the customary no-till arguments of dramatically reduced weed seed germination as well as moisture retention. We were impressed by the drill’s consistent seed rate, robust build and low draft requirement.

We do suggest Agrisem addresses various details: stickers falling off, poor calibration trays, the cumbersome process of changing the seed pipes, the chains on the metering units and the ladder. Distribution across the rows and the transport width also need some work. Overall, it is a solidly built and reasonably priced direct drill that can turn its hand to sowing into previously worked ground.

Lüder Görtmüller, Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.