The ASG contracting business specialises in potato establishment. The Nortrup-based company also focuses on services for dairy farmers in this part of Germany.

KEEPING IT BRIEF

- ASG plants over 2,300ha of potatoes every year with its 10 planters.

- It also runs six Grimme harvesters, two of which have driven axles.

- Other mainstays of the business are machinery hire and dairy farm related services.

Potatoes are a major crop in Lower Saxony — last year 6.1 million tonnes were harvested from its 139,800ha, meaning this northern state is the highest yielding region in Germany. Many farmers within the Osnabrück area grow potatoes for processing into products such as French fries and crisps, with producer groups coordinating sales and agronomy advice for their members.

Agrar Service Nortrup is a major agricultural contracting business that specialises in the potato crop. With 10 spud planters and six harvesters, the team mainly works within a radius of about 50km of its base near the small town of Nortrup, travelling farther for larger jobs. For example, one ASG planter is currently working 85km away, as there is a sizeable area to plant. Most of the growers ASG works for are longstanding customers who have developed their potato businesses alongside the specialist contractor, and the way they work together is shaped by that shared experience.

That said, new customers are added every season. Scheduling and dispatching the big potato fleet is the job of the firm’s boss, Karl Pieper. The ASG managing director has been involved in growing potatoes for over 20 years, and he is always on hand to answer customer questions. He places particular importance on communication, especially during the planting season.

Planting

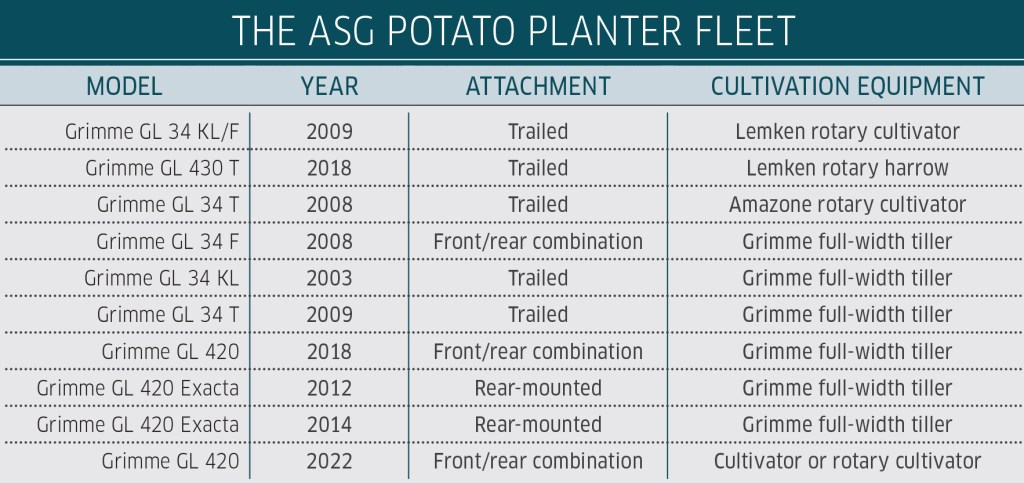

By early May, the potato planting campaign is drawing to a close. The team has planted around 2,200ha of the targeted 2,300ha. Ten Grimme planters stand ready on their marks, each with slightly different kit to master varying conditions.

Almost all machines are fitted with an APV spreader for microgranular fertiliser as well as being equipped for tuber and in-furrow treatment, with the contractor supplying the granules and dressing products together with the machines, if the customer wants. Large-scale growers can collect the products by the pallet or have them delivered. As Karl is purchasing in larger amounts he is able to negotiate better prices.

The soils in this region range from light sand with an index score of less than 20 up to medium-heavy land with a score higher than 60. For the light land, there are five power harrow/planter combinations. The fleet also included seven bed tillers for tougher soil conditions such as last season when they were used to break up the hard clods from the baked ground.

Ridgers

When it comes to ridging, every customer has their own preference. The contractor runs four standard ridgers, five machines with speed ridging plates and one with cage wheels.

The speed ridging plates produce smooth, firm and very large ridges. Yet on heavy land, this system can lead to the soil capping on the ridge, which the emerging plants will then have to break through. This capping can happen when the tubers are planted into wet soil followed by a dry spell. On light ground, by comparison, the plate system effectively protects against erosion and produces very stable ridges.

Cage wheels are mainly used on lighter land where they produce a porous ridge. This type of ridge is popular within areas that will be irrigated later in the season. Growers reckon the porous ridges soak up the water more effectively, and they have also found that they hamper weed growth compared to smooth ridges.

Many customers prefer the standard ridging bodies. Forming slightly smaller and more porous ridges that absorb water effectively, they don’t cap, even on heavy soils.

For the upcoming season, Grimme’s new Prios planter with a hybrid ridging system is expected to increase the fleet’s flexibility, because the ridge-forming system can be quickly adjusted to current soil and weather conditions, for which you simply refit the individual components.

Logistics

The logistical challenges of contract potato planting are considerable. Not surprisingly, communication and planning are essential to ensure the right machines arrive at the right field. ASG uses a monitoring system to keep on top of this. Drivers can find all of the necessary information regarding the fertiliser, seed dressing and the type of potatoes as well as the field and customer details. Customers look after the logistics of handling the seed potatoes. They also have to supply a loader in the field for filling the hopper. Customers are also responsible for checking planting depth and spacing.

“As a contractor, we are responsible for the quality of our work,” explains Karl. “But it is important that the customer shares some of the responsibility and continuously checks all parameters. Ultimately, this cooperation also benefits the customer. Our prices are a combination of per ha and hourly rates.”

Previously, the required planting depth and spacing for up to 22 different varieties were noted on information sheets for the planter operators. The customers grade the potatoes into suitable sizes and and remove oversize seed.

ASG only uses cup planters. The exception happened in 2024, when a shortage of seed potatoes meant they briefly needed a belt planter. Customers clearly prefer the cup planters, not least because of their more accurate seed placement.

ASG’s customers are also responsible for supplying water for the seed treatment unit. Fertiliser is applied as microgranules; starter fertiliser is not used.

Around 70% of growers apply phosphorus fertiliser, typically Power Start micro K from Agron. As well as 12% nitrogen and 40% phosphorus, the fertiliser product contains magnesium, sulphur, boron, manganese and zinc. There is also an increasing demand for GPS-based section control for shutting off individual rows. Customers are stepping back from planting using application maps, even though some of the machines have this capability.

To keep the planter fleet up to date, regular investment is essential. For the 2026 season, the business has ordered a GL420, an Exacta 420 and a Prios 440.

“We want our machines to be state-of-the-art, although the new Prios will still have to prove itself on our farm,” says Karl, who prefers a mixture of modern kit and proven machines, as this allows him to meet very different customer requirements. Versatility is important to him: “With the Prios we are much more flexible in terms of cultivation and ridge formation — and that is crucial for us as contractors.”

Row crop work

The business has relatively little to do with in-crop work. Most customers look after crop protection, fertiliser application and irrigation themselves. Before lifting, some growers will ask the contractor to either flail the potato top or hire a topper from ASG and do the job themselves.

The main work for the Nortrup contracting team is preparing fields. Regular jobs include mulching cover crops, spreading lime and cultivations. Another important pillar for the business is spreading slurry, and it has recently invested in a tridem, a tandem axle and a ferry tanker all from Wienhoff. It now has a total of five tankers that are available for hire.

The company also handles brokering slurry for its customers so that the manure can be supplied to potato growers in the area and not hauled long distances.

Harvesting

For harvesting, four Grimme Evo 280s plus a pair of SE1560-60 harvesters along with several tractors and trailers are available to lift around 1,100ha of potatoes. Two of the harvesters have driven axles to deal with difficult conditions.

This means Karl Pieper always stays on top of things. There is always increased demand in wet years from new customers. “However, our long-standing customers take priority — especially in such exceptional situations,” stresses the MD.

Further specialisation

Apart from potatoes, the business offers a wide range of services for dairy farms. Four forage harvesting gangs, three big mower combinations and a trio of four-rotor rakes deliver efficiency in the grass harvest. In summer, seven combines, five big square balers and two round balers are normally kept busy.

To ensure all customers receive enough straw, the firm also runs a straw trading operation, which also takes care of logistics. During maize harvest, the business operates five foragers, with one kept in reserve for late grass throughout the autumn. Last but not least, two mechanics from the workshop handle repairs.

Summary

Agrar Service Nortrup (ASG) is a German contracting firm that specialises in potato planting and harvesting. But that’s not all; it also offers a wide range of other services. Dispatching potato kit in an ag contracting business is a demanding job that requires good communication as well as a flexible fleet that is able to meet customer demands and conditions that vary year by year. Life is never dull, that’s for sure.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.