For its new generation of Matrix precision planters, Grimme has listened to customer feedback. We noticed lots of significant improvements over the Gen I version in our exclusive practical test.

KEEPING IT BRIEF

- The new Matrix has a number of really nice details.

- It is particularly good when it comes to maintenance and handling.

- Seed detection and signalling proved excellent in the lab. In-field measurements were slightly better than on the Gen I machine.

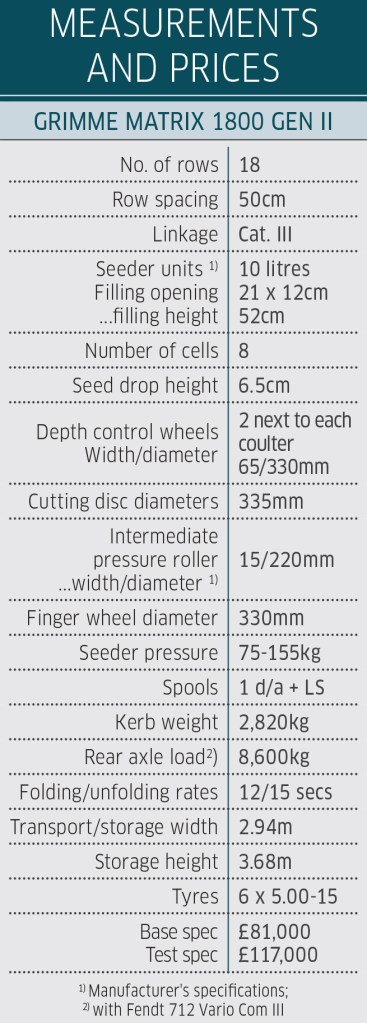

The order book is now open for the second generation of the Grimme Matrix precision seeder in both Classic and Pro variants. The two versions of the 12- or 18-row machines (45cm or 50cm spacings) differ mainly in how the coulter unit is pressurised down.

Back in profi 11/2024, we looked at the simple Classic version with spring tensioners for a quick driving impression. For this practical test, Grimme sent us a an 18-row Pro with the hydraulic downforce system.

Coupling up is quick and easy: three pipes for the load-sensing hydraulics, a double-acting spool for the bout markers; then just plug in the lights and ISObus. Final part of the coupling puzzle is the rope that opens the emptying flaps, along with a control box with emergency stop and field/road mode selector that also goes into the cab.

Easy parking

The integrated parking stands and gauge wheels with a storage position are a real plus point as they make it easy to park up the machine. All six gauge wheels usefully swing up out of the way for servicing and working around the seeder units. It is these details that make life with the Matrix II that bit nicer.

For levelling out tractor wheel tracks, there are spring tines or alternatively eight lighter tine harrows that have height and angle adjustment (£1,015). If there is a lot of organic material, the tine bar can be quickly removed, which is great. However, it remains to be seen how durable the eradicator tine frame is in the long run.

Maintenance-friendly

Grimme has come up with very practical solutions for swapping the cell wheels and coulters. For example, there are no longer outer cover rings on the cell wheels, which makes emptying easier. How this lack of protection affects performance in difficult soil conditions remains to be seen — we were blessed with predominantly good conditions for the test — however, this was the same set-up as the first generation.

Regarding emptying, the spring-loaded flap on the right side closes securely, and edges are no longer as sharp as on the Matrix 1. However, after emptying, there was still a shotglass of seed left in each hopper, which is not ideal. We would have preferred a suction solution with a suitable attachment to ensure that the hoppers are completely emptied.

The 50mm high mulch seed coulters are available in different lengths and are easy to change. Rather than using roll pins, this is done with two screws per coulter. The cutting edges of the coulters are made with Widea steel, while the flanks are made of Hardox. The discs and gauge wheels can also be easily removed using an impact wrench. Thanks to removable shims between the discs, wear is quickly compensated for.

Setting made easy

The machine also scores points for its ease of adjustment: sowing depth adjustment, cover discs, and intermediate press wheels are all easily accessible. A useful addition would be a limiter for the forward movement of the cover disc handle. The seed hoppers hold 1.5 units or 10 litres of seed — just right. The hopper opening is sufficiently large, and the internal scale is a neat detail.

The Matrix’s hydraulic rams inside the sturdy parallelogram linkage for each row are now better sealed. We measured the coulter pressures, which ranged from 75 to 155kg on our Matrix Pro. Downforce pressure can be increased in 5% increments on the cab terminal or Aux-N buttons — all excellent stuff.

Higher coulter pressures are possible in the tractor wheelings thanks to stronger rams. You just need to be aware that, up at full pressure, the machine can start to lift out of work slightly.

The user cannot remove the pressure from individual rows, but they can be raised to indicate tramlines.

Visibility is good on reconsolidated soil, but not always on looser ground. For the UK market, hydraulic coulter pressure is a standard feature.

Good single metering

Although Grimme now uses eight instead of six cells per metering disc, the proven system continues to do its job precisely.

In our lab test measurements, we had hardly any duplicates or defects, and the standard deviation was also excellent. Out in the field, however, the actual standard deviation, with values between 21.35 and 25.55mm, was on a par with a previous test carried out in 2018 (albeit this never appeared in profi international).

This time, however, the proportion of plants within +/-25mm was better, achieving its best results at 7.5km/hr, but also performing pretty well at higher speeds.

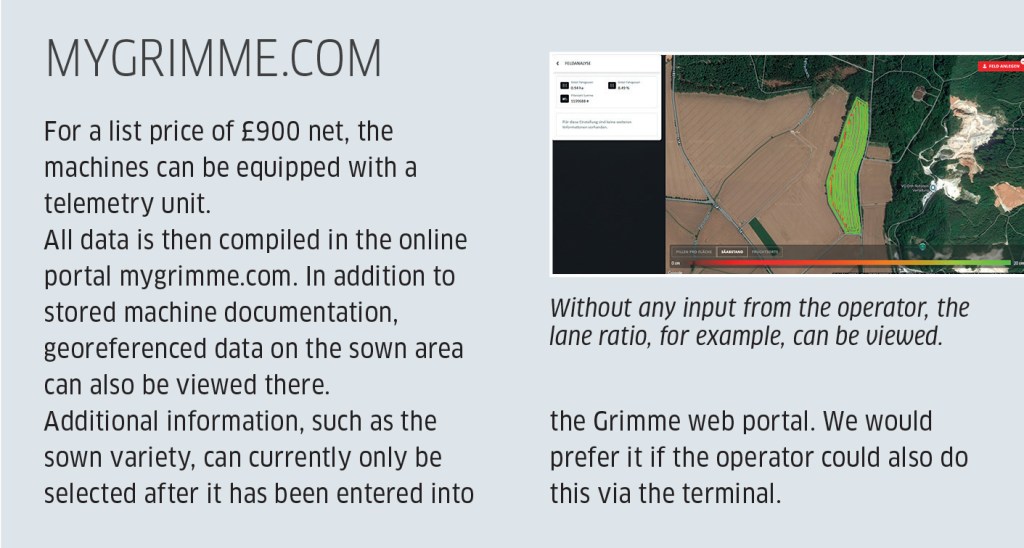

Operation is almost intuitive thanks to the clear ISObus interface and setting tabs. We always recommend functions like Clever Planting (closer planting next to the tramline) and Section Control (£1,430). Additional licences such as for variable seed rates (£1,170) or Tramline Control (€400) are also available as needed. However, our testers recommend this function immediately if you have a Tramline-compatible terminal.

Good news: Grimme plans to reactivate all automatic functions after transport by the 2026 season. They also plan to implement a second spacing option, even with Aux-N functionality.

The optical sensors work very reliably and, according to Grimme, even detect rapeseed. We made little use of the sacrificial row function with increased seeding rates at field boundaries — as well as the adjustable planting windows, which we only consider useful for 45cm rows.

Other details

- Compared to the earlier Matrix 1, our Gen II test model weighed about 140kg more at 2,820kg.

- Bout markers (£2,045) fold horizontally which is good for field boundaries.

- The parallelogram-guided and height-adjustable clod scrapers (around £4,000) are now much more practical, but probably only relevant for a few people.

- The machine folds just as fast as the first generation — great.

- The Pro version only offers space for two seed storage hoppers — not enough.

- High price: while the base machine starts at £81,000, the test machine climbs to £117,000. In 2017, the comparable 18-row Matrix without pre-em markers and clod remover, but with terminal, was in the region of £75k.

Summary

Grimme has made numerous improvements to user-friendliness with the new Matrix generation. The optical sensors, coulter pressure and folding kinematics are very impressive, and the practical details make everyday use of the machine very pleasant. Singulation and field emergence are also good to very good. The high overall price may well be a deterrent. Criticism is only reserved for minor details.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.

KEEPING IT BRIEFTThe new Matrix has a number of really nice

Seed detection and signalling proved excellent in the lab. In-field measurements were slightly better than on the Gen I machine.