Long term, the Fortis LT is set to supersede the four-row Terrano GX.

Horsch has added extra metal while making the machine shorter, yet it’s still able to manage trash flow as a shallow or deeper working tool.

KEEPING IT BRIEF

- With the Fortis LT, Horsch is responding to the increase in horsepower on farms.

- Marries up a large frame with familiar soil-engaging components.

- New chassis makes it relatively compact.

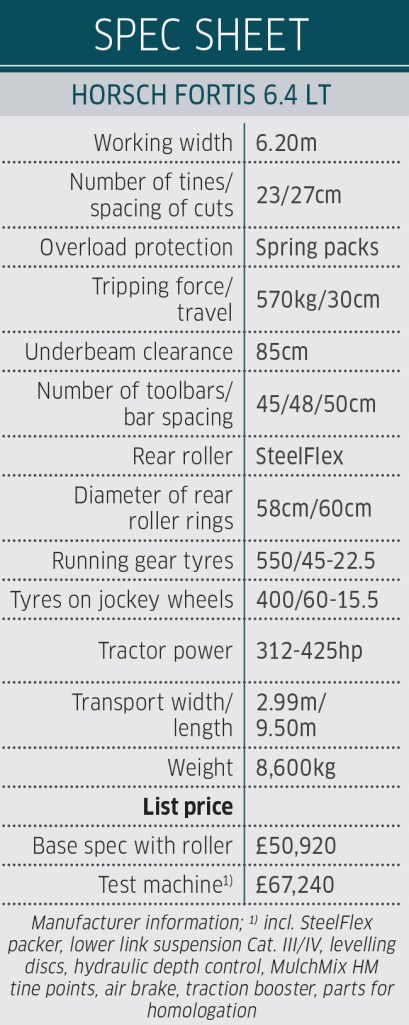

As tractor horsepower increases, implements clearly need to keep pace. A new universal cultivator from the Horsch stable is the Fortis LT, a machine that’s able to tickle the top or delve deeper after a change of points. It has a beefed-up frame compared to the Terrano GX that it will replace, but it’s more compact and lighter than the Fortis AS.

We used a New Holland T8.435 to pull the 6.20m wide cultivator across some stubble, the 435hp on tap also being the maker’s recommended maximum power for this working width. Yet, with the tines sunk to 20cm, the tractor had no power to spare — we certainly wouldn’t have wanted anything less up front.

This also immediately reveals how it differs from the Terrano GX and heavier spring, deeper working Fortis AS: the 5.90m Terrano GX is rated for a 350hp; the Fortis AS is a 550hp machine.

Back to the Fortis LT, and Horsch is currently offering this four-row tine cultivator in working widths of 4.60m, 5.60m 6.20m and 6.70m, the numbering in the model name 4.4, 5.4, 6.4 and 7.4 not exactly marrying up with the amount of ground covered in each pass. Incidentally, the widest Terrano GX is 5.90m.

Familiar components

Starting at the front, the Fortis LT is coupled with either a lower link crossbar (Cat. III or IV), K80 ball or the floating drawbar (Cat. IV or Cat. V). Because most of these cultivators are ordered with a weight transfer, traction booster, it comes as standard on the Horsch.

Integrated into the drawbar, it can transfer up to 1.20t on to the tractor’s rear axle. To prevent this from lifting the front of the cultivator out of the ground during shallow work, it can also be deactivated.

Up front, our machine was equipped with twin gauge wheels (standard on the Fortis LT 6.4 and 7.4). Horsch recommends these for light soils and/or shallow tillage work due to their much larger footprint, which also makes them less sensitive to uneven ground and wheel ruts.

At the same time, the wheels form part of the depth control system together with the rear roller. The cultivator we used was also equipped with hydraulic depth control, where all the cylinders are interlinked in a master-slave system. Alternatively, there is a hydraulic version with shim clips for each ram as depth limiters, or an all-mechanical limiter that also uses clips. The version we had is definitely the most convenient to operate, but, due to the additional plumbing complexity, it is also the most expensive option — so, it’s a question of comfort versus budget.

Levelling tools move closer to cultivating tines

The tine section itself is split into two parts and offers a decisive advantage over the Terrano GX: the axle for the running gear is no longer positioned between the last row of tines and the levelling tools, but sits in the last tine row. This may not sound like too much of a difference, but it significantly reduces the space the transport wheels need for swinging up and down. As a result, the levelling tools are positioned closer to the rear row of tines, making the whole machine that bit shorter than a GX.

Another upside is that, the cultivator should better handle hills/dips. When the wheels are raised in work, they lift high enough that the neighbouring tines can still fully trip without snagging the tyres — very good.

For the tines, Horsch uses its well-known TerraGrip tine; on the LT these have a trip force of 570kg. The frame height is 85cm, which, together with tine spacing of 27cm, provides sufficient room for trash to pass through.

The full arsenal of Horsch points is on offer, from the 25mm narrow points to 40cm wide shares. Working depths of up to 30cm are possible, depending on the type of point fitted. Our machine had the MulchMix HM, a wedge-shaped point that was capable of good penetration.

Adjustable double rolls

At the rear we had the SteelFlex roller — an interlocking press with a 58cm diameter DD- style ring running ahead of a 60cm diameter leaf spring ring. This combination is reckoned to combine deep reconsolidation with a good tilling action — which is what we found in our test field. You can also opt for the double RollPack packer, a tandem U-profile ring press, or there is also the wedge ring style OptiRoll packer.

We did like that you could alter the distance between the two rolls on the double press, which could be beneficial where stones can get trapped when on a closer spacing. An angle adjustment is also available as an option; this can then be used to raise the front roller slightly, for example, to prevent soil and residues from being pushed up.

Summary

The Fortis 6.4 LT did good work in the field, mixing in chopped straw to a depth of 20cm. We couldn’t work any deeper in the wet loamy field with the available horsepower, but likewise the farmer was happy with the job being done. Levelling and reconsolidation were also spot on.

Our initial impression is that the Fortis LT is a better machine than the Terrano GX. Of course, this does come at a price, with our fully specced 6.20m unit listing at £67,240.

Andreas Holzhammer

For more up-to-date farming news click here and subscribe now to profi and save.