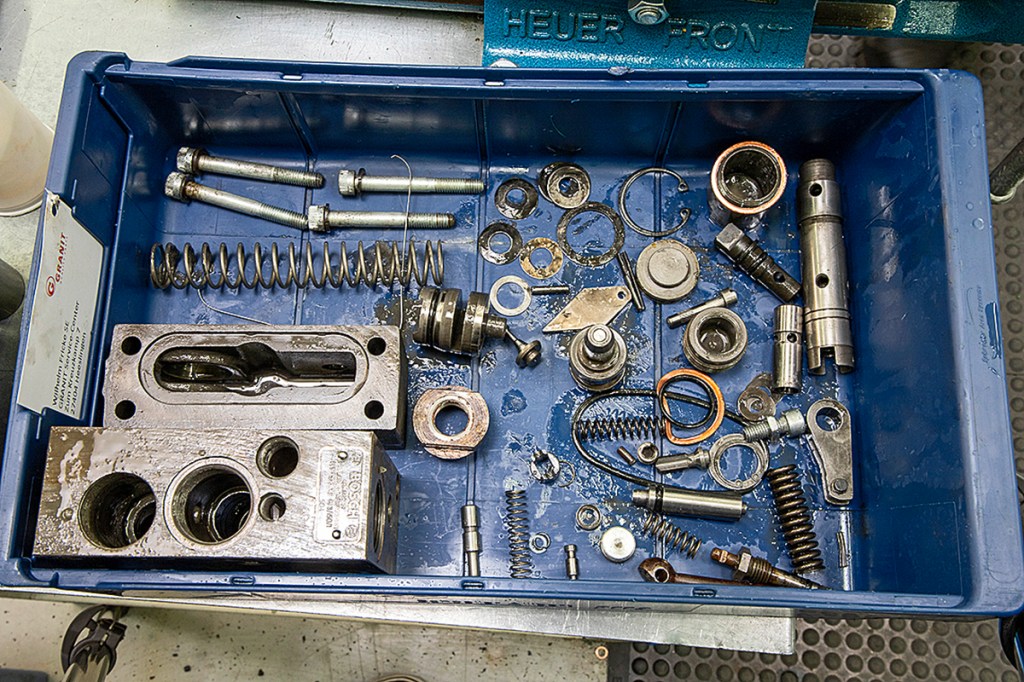

Hydraulic control units have undergone a great deal of development over the years, but the basic mechanical elements still work to the same principles. Here we describe a repair carried out by Bosch specialist Granit Service Centre.

KEEPING IT BRIEF

- Hydraulic systems became universally adopted on tractors from the 1950s.

- Granit Service Centre tests, repairs and calibrates Bosch hydraulic control units for industrial and agricultural applications.

- Contaminated hydraulic oil is a key cause of problems.

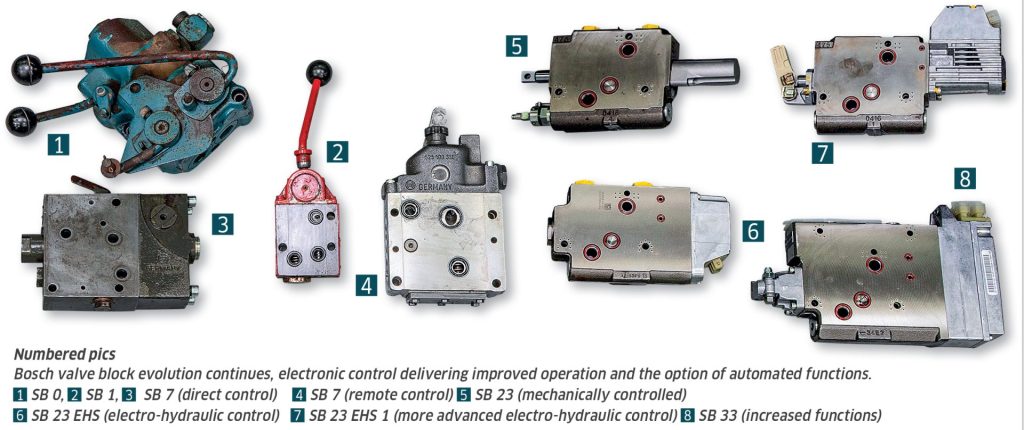

Bosch SB series ‘Steuerblock’ hydraulic block control units have been around in one format or another for years, with variants evolving from basic single/double-acting valves through to the considerably more advanced multi-function blocks with features to include float and load sensing through to options for electro-hydraulic integration for much more precise implement control.

In broad outline, key Bosch designs include:

SB1: Early, simple control unit for single/double-acting hydraulic cylinders with the basic lift/lower operating functions with manual lever control.

SB7: Next step up in hydraulic control evolution, with Lift, Neutral, Lower and Float positions, with the option of detents and limit switches for automatic functions. Switchable between single- and double-acting.

SB23: Introduced a more sophisticated control, including load-sensing SB23 LS variant with hydraulic motor control and SB23 EHS electro-hydraulic system. Popular block series used on tractors for 35 years.

SB33: Developed to provide increased functionality around 15 years ago.

Aside from offering increased functions, valve block control improvements have also focused upon reducing oil leaks, to allow higher flow rates. Modern systems span compatibility with different control systems from levers and cables through to full electronic systems. What hasn’t changed is that dirt and debris plus simple wear can eventually lead to problems.

Hydraulics experts

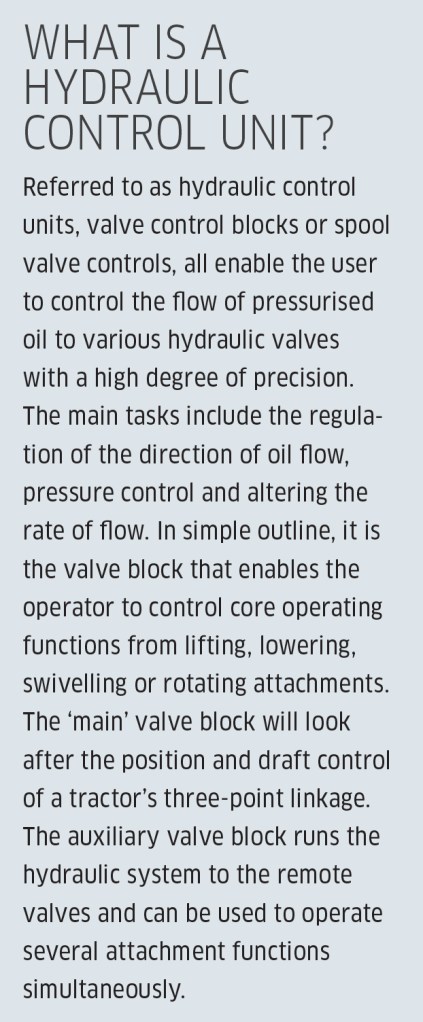

To get an insight into how hydraulic control unit valve blocks are checked and repaired, we visited licensed Bosch service agents, Granit Parts, in Heeslingen, Lower Saxony. Here hydraulic specialist Phil Betz outlined what it takes to repair a broad range of valve blocks, his knowledge extending to older systems going back to designs first used over 60 years ago. Among the variety of test benches used is an IH tractor block adapted to test Sens-o-draulic units first seen on these tractors in the early 1980s.

Common problems

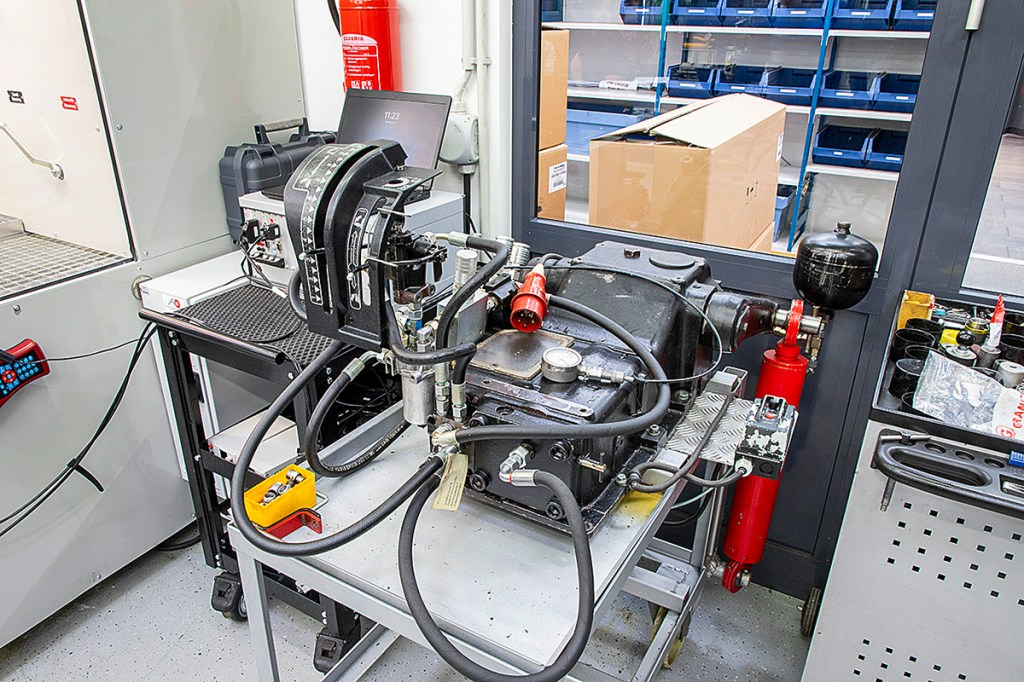

Typical problems include leaks, units no longer maintaining pressure or constantly readjusting without any operator input. These faults almost always indicate wear or defective parts inside the control unit with contamination, particularly in the spool that diverts oils to the remote valves plus brittle seals, worn gate valves and valve seats typical causes.

Repair process

Repairs start with the control unit being completely stripped, with each individual component inspected for any damage and wear.

Following initial analysis, the customer receives a repair cost estimate, work only proceeding if the estimate is approved. The components are then thoroughly cleaned, worn parts replaced or refurbished where possible and all seals and support rings replaced.

Once the necessary repairs have been carried out, the valve block is tested using a custom-made test bench. This simulates work cycles and enables the fine-tuning of the various valves and settings to be made. A standard load of around 800kg is applied, this being sufficient to identify any system leaks or problems.

Repair costs

Refurbishment costs will obviously depend on the model of valve block being repaired and the level of work required. Typical costs will range between €200 and €800. Granit do offer the option of a reduced cost fix where a full refurbishment may not be necessary, such as when repairing a unit from an old tractor that will not be called on for front line service. When seeking a repair for older ‘project’ units, it is best to seek advice.

Replacement as an alternative

The Granit Service Centre retains an extensive range of ‘new old stock’ parts to enable it to repair older and now obsolete valve blocks, though there will be a point where a repair is no longer feasible or cost effective. Granit can supply third party alternatives to Bosch items no longer in production.

Removing and refitting valve blocks

Job one is to clean around the valve block before removal. If possible, take a picture of all the connections before disconnecting them and label pipes to be sure you don’t mix them up when it comes to refitting the block. Take care, too, when removing the unit, as the shuttle valves in some designs can drop out. Cleanliness is particularly important during re-installation as no dirt must get into the hydraulic system. Even a small amount of dirt can clog small holes and components that have been cleaned and repaired, undoing all the good work you have paid to have carried out.

A point that may be overlooked is that the repaired block should not be ‘operated’ before it has been installed. Fiddling with the unit can lead to overloading and the blockage of various control elements.

On more modern and advanced items of equipment with electronic controls you need to be aware that various components must be compatible and replacements may need to be set up with the correct operating software. If in doubt, seek advice.

Maria Henkemeier

For more up-to-date farming news click here and subscribe now to profi and save.