When it comes to cultivators and drills, it seems there is lots of potential for on-farm tweaks and mods. Sönke Schulz has been through the profi back catalogue to pick out some of the more interesting highlights from our ‘Tuning’ series.

A LIGHT FOR NIGHT SHIFT

The seed hopper tends to block the illuminating power of the tractor’s work lights on the coulters. To keep an eye on their progress, Martin Pilwarsch installed two lights on the rear platform. He didn’t even have to drill any extra holes.

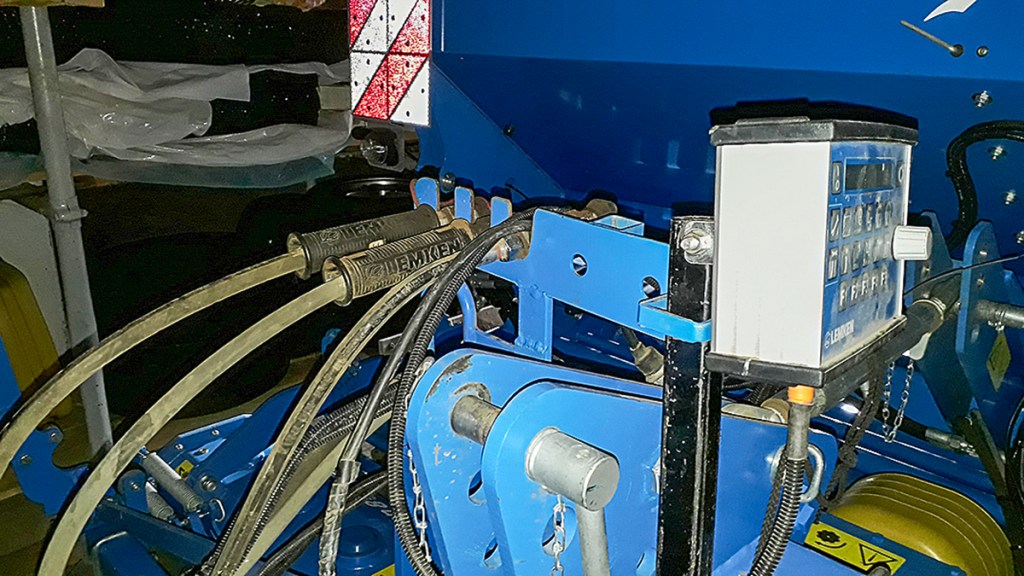

HOSE HOLDERS

Martin Pilwarsch’s Saphir 7 didn’t have a hose holder, so he made his own. He cut out some simple drop-in slots for the hydraulics and electrics as well as adding a holder for the control box.

STORAGE BOX AND HOLDER

To make sure they always have spare points, Markus and Ulrich Müller added a bracket to store some extras on. The silver toolbox is home to spare nuts and bolts.

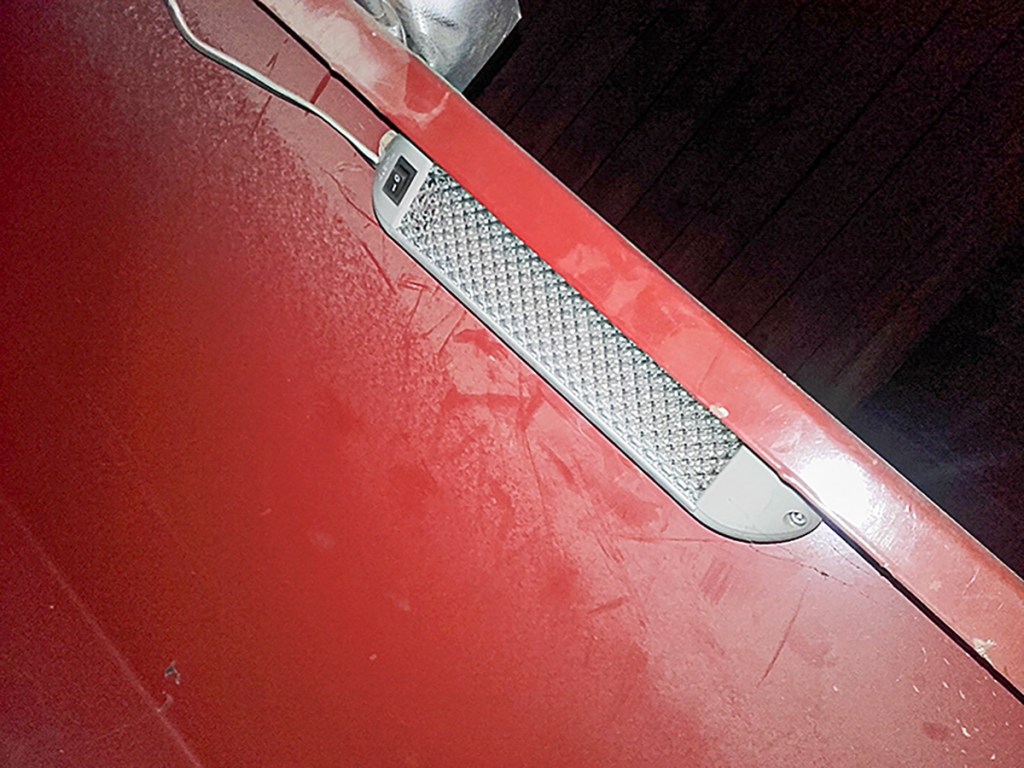

LIGHT ON THE PLOUGH

Harm Noltemeier spent a long time looking for a practical solution to fit some road lights to his Lemken Variopal 8. This was the solution he came up with: LED lights housed inside a short length of channel fastened to the plough. He then routed the wiring along the beam.

ROLL WITH IT

The lights and holders were not the only workshop mod Martin Pilwarsch did to his Lemken Saphir 7 drill. He also built this cultivator for when he didn’t need to use the tilling ability of a power harrow. He picked out an old packer roller and made the headstock and frame along with mounting points for the drill. Spring tines are fitted as track eradicators. This allows the drill to be operated with a smaller tractor when sowing cover crops.

HYDRAULIC MARKER CONTROL

Johannes Elseberg solved a problem he had with his Amazone D7: when the drill was mounted on a power harrow, he couldn’t reach the manual lever for the bout markers, so he converted it to hydraulic operation. The ram is equipped with a flow limiter so that the lifting speed can be adjusted. The ram was in the scrap yard and didn’t cost much. Chains allow him to alter the lift height — both markers are raised about 20-30cm when the ram is halfway out.

PIPEWORK FRAME

This delivery pipe is fitted to a Fendt 828 Vario. The pipe rests on two separte holders. One is bolted to the step, next to the cab. The other holder is inserted into a mounting bracket and bolted in place over the mudguard.

BARBECUE DRILL

Just because its seed sowing days have finished doesn’t mean a drill has to be parked in the hedge. This novel BBQ was spotted in Luxembourg. The seed outlets provide air flow, and the lid can be closed to hold in heat for indirect cooking. Yum, yum.

DRAINAGE PLOUGH

A reel was installed on this single-leg subsoiler so it could be used for laying drainage pipe, cables and water hose. There is an 80mm diameter pipe welded to the back of the leg with a 90° bend at the end. Up top, several cuts were made so the opening could flare out to ensure 65mm drainage pipe could easily pass through without snagging. To ensure the pipe doesn’t wear, old plough landslides were welded to the leg. The reel is a wheel rim running on a modified bearing.

LET THERE BE LIGHT

This Accord drill was treated to a lighting package. This includes a retrofitted work light that sits above the power harrow to illuminate the area to the sides. A waterproof LED camping light was also fitted in the seed hopper, making it easier to check the level and to refill.

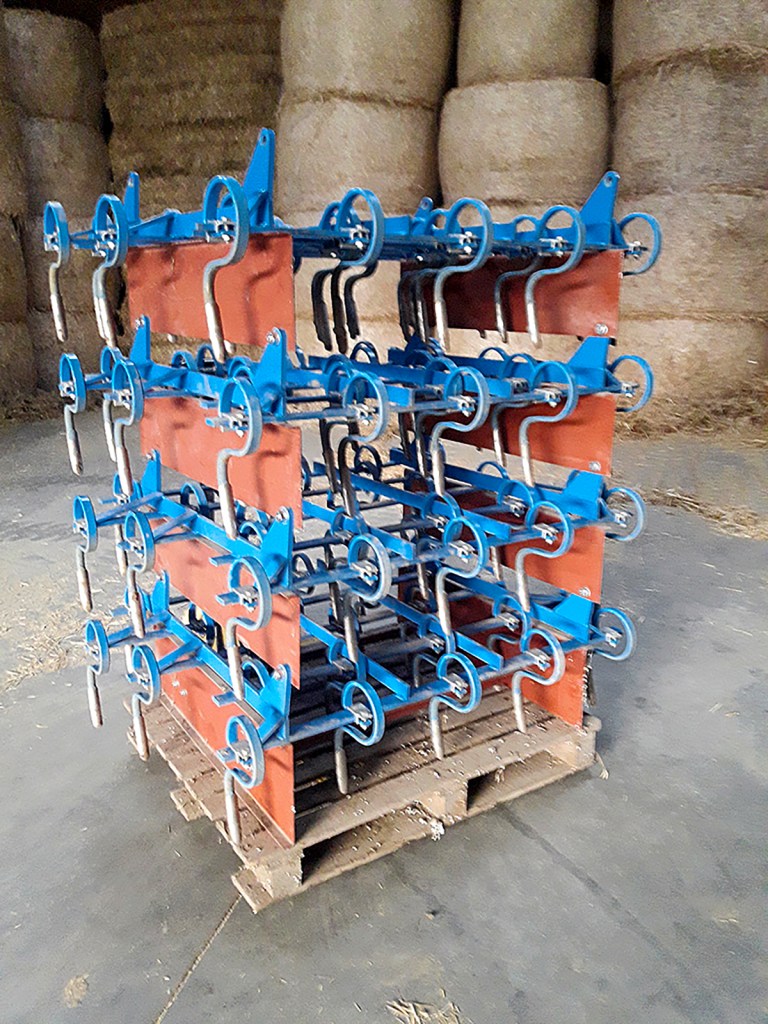

SECOND FRAME SWAP

Rather than replace each tine on his Lemken Korund for different jobs, Kilian Wolf fabricated a second set of tine frames, making it much quicker to swap. And to ensure the spare tine frames don’t take up much storage space, he also came up with this racking system. They are strapped in place when the stack is being moved to the corner of the machinery shed.

ELEGANT ROUTING

DIY solutions for installing seed/fertiliser pipes along the tractor remain a popular topic (profi 8/2025). These Väderstad pipes ae mounted on two attachment points. The first consists of a bracket on the handrail and attached with pipe clamps. At the rear, the maker board arm was used to mount the half shells supplied with the hopper.

For more up-to-date farming news click here and subscribe now to profi and save.