Realising it needed a 114-134hp powershift, the SDF engineers have pulled off a blinder – they used the tried and trusted inhouse CVT and added some steps thus creating the new 6C RV Shift. We find out what it is like to drive and who it is aimed at with our first look.

With the launch of its new 114ph – 136hp 6C tractor range Deutz Fahr has taken the unusual decision to add simulated steps to its home-

built CVT gearbox. Potential purchasers now have the option of choosing from the company’s confusingly titled ‘Powershift’ manual stick- shifter, its in-house built TTV stepless box or this latest variant – the RV Shift.

Using the same mechanical underpinnings as its CVT stablemates, the new option brings 20 computer-generated steps in the forward travel range and 16 in reverse all through a simple to operate interface that you can jump on and drive says the maker.

It’s a slightly baffling concept but Same Deutz Fahr isn’t the first manufacturer to do it. When Fendt was battling to break into the fiercely powershift-loyal North American market in the early 2000s, the Bavarian tractor maker put simulated powershift ‘gears’ in place in its trademark Vario stepless gearboxes. It’s unlikely that the strategy was wholly responsible for Fendt growing its market share in the US and Canada but its fair to say two decades on the brand now has a credible position in that region. JCB too had a powershift mode on the CVT equipped Fastrac 8000 when it hit the market 17 years ago.

Using similar logic SDF says that it can grab a much bigger share of the European market by offering a powershift. The company says that currently 13,000 out of 18,000 tractors in this power bracket are sold across Europe each year with ‘robotised’ semi- and full- powershift transmissions. By not having such an option in its midsize line-up it believes it is missing out on a huge chunk of the market – possibly up to 70%.

Now focused on grabbing a slice of that action SDF says it has come up with a solution.

Given their size, many 6Cs are likely to be put to work on materials handling duties. Stoll loaders are painted lime green and stickered with the Deutz flash for this purpose. Brackets and plumbing can all be factory-fitted to avoid unnecessary spanner rash.

Adding steps

Without an existing transmission in its portfolio the company says it would struggle to justify the expense of developing such a box and is reluctant to use a third party supplier. Instead it has decided to make use of its Treviglio-built TTV gearbox dividing up its two stepless travel ranges into 20 fixed ‘ratios’. Not only does this necessitate a totally different driving style but operators also get a completely different control layout too – something SDF says will help to provide greater differentiation between the three variants within the 6C series.

While it goes without saying that pricing varies between 6115, 6125 and 6135 models, buyers of RV Shift-equipped tractors can expect to pay around £6,000 less than those opting for the stepless TTV box. With its five mechanical gears and either two or three splits, the bog-basic ‘Powershift’ version comes in a further £6,000 cheaper.

So what do you get for your £6000?

Externally the tractor appears much like its siblings – just the ‘RV Shift’ flash on the bonnet giving away its identity. Climb up into the cab and things start to change.

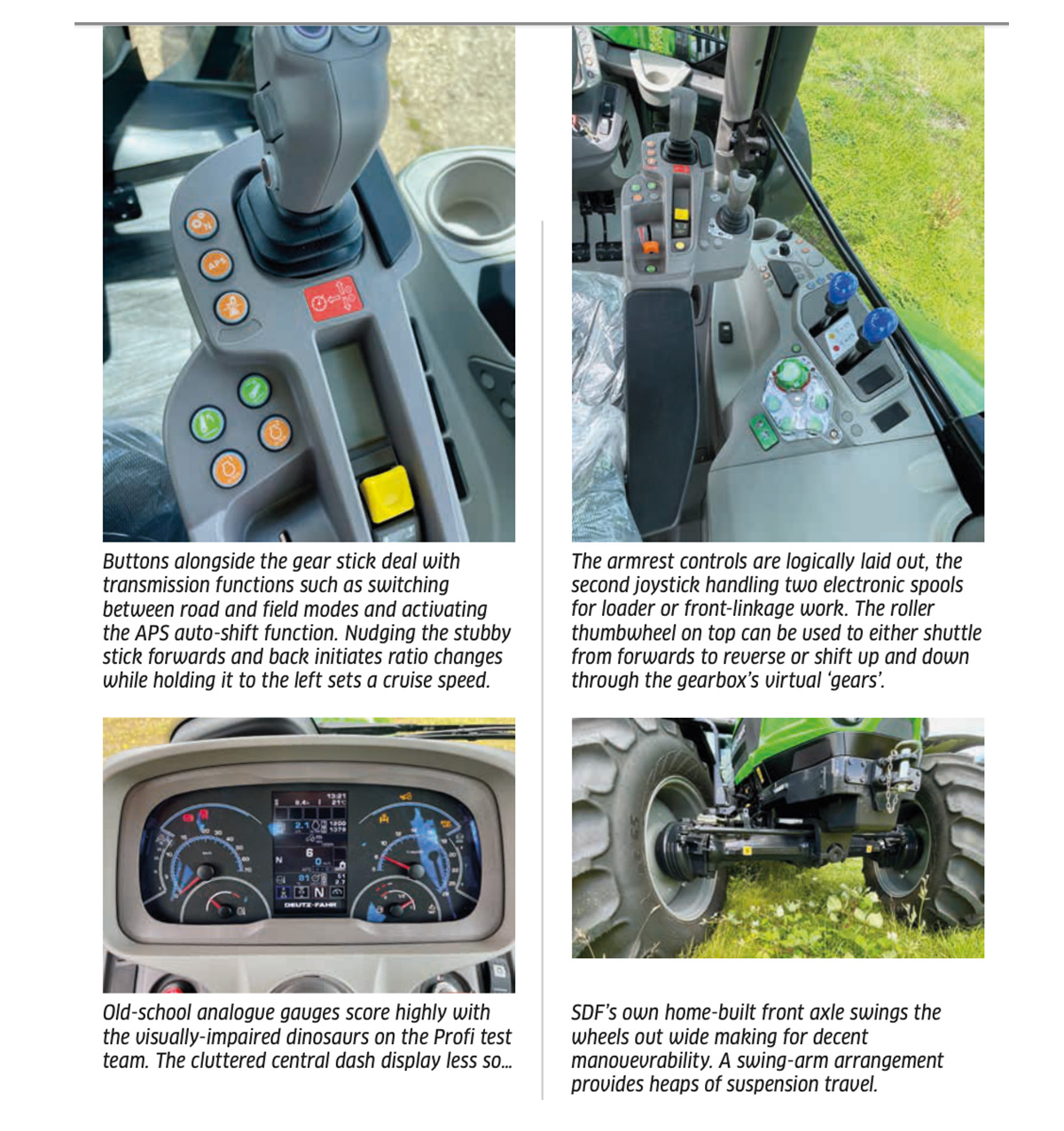

Deutz Fahr has stuck with its trademark kindergarten colour-scheme – blue for hydraulics, green for linkage, yellow for pto, orange for engine and transmission – but the control layout is something completely new. Unlike stick-shift 6Cs which have everything grouped on the right-hand console, RV Shift tractors gain an armrest mounted pod which hosts a stubby gearstick, throttle slider, a sprinkling of buttons for various automated functions and a second cross-lever should a loader or front linkage be fitted. They do, however, lack the sculpted multifunction handgrip and Topcon-sourced IMonitor touchscreen that typically come as part of the TTV spec package.

Same Deutz Fahr management hopes that alongside its edgy angular styling, the RV Shift gearbox will help 6C tractors to grab a bigger share of the all-important middleweight powershift market.

In the seat

To operate RV Shift tractors are pretty straightforward. With the long, wand-like shuttle lever shoved forward the machine takes up drive (so long as the hydraulic hand- brake is released). Forward and aft nudges of the stubby gearstick take it up and down through the virtual powershift steps. Although not jolty, these up- and down-shifts are remarkably realistic and it’s impossible to tell that underneath your backside there’s actually a seamless stepless CVT working away. It all feels much like a Massey Dyna-6, New Holland RangeCommand or Deere DirectDrive box to operate.

Like the competition Deutz offers an auto shift function. Tagged APS, the up and down- shift points can be selected in a menu page on the colour dash screen. A BMW-style click- clack encoder dial is used to scroll through the various pages which, thanks to easy to fathom icons, are clear and easy to work with. In addition to this ‘Road’ and ‘Field’ modes provide upper and lower virtual gear limits – from the factory the former is set so that the start off gear is nine and the box will run all the way up to step 20. In Field mode a working range of, say, ratios five to eight can be set, again all done in a relatively straightforward manner via the dash display and rotary encoder dial.

While having these automated functions is great, it’s hardly a gargantuan effort to flick the gear lever forward and back to initiate a change in pace. To add to that the set-up also incorporates a sequential shift function – hold the stick forward and it’ll notch up through the ‘gears’ one-by-one. Doing that with the joystick’s consent button pressed will prompt the gearbox to skip shift, jumping two to five steps at a time – good for getting away from the lights when you’ve got Max Verstappen on your tail.

Once up to speed, nudging the gearstick to the left activates a simple cruise function, maintaining the chosen pace. This can then be fettled and tweaked with a thumbwheel on the multifunction lever.

Also clustered around the handgrip are a quartet of amusing-titled ‘Jolly’ buttons – apparently assignable via the dash to various functions including the shuttle. Rapid direction changes can then be initiated when your left hand is otherwise engaged with a squeeze of the appropriate button at the same time as the consent key on the front of the joystick.

One of the few optional extras on RV Shift tractors is a creeper function. Of course, having a hybrid hydrostatic/mechanical CVT ‘box between the engine and backend means it’s possible to generate super-low ratios without the need for an additional dedicated creeper box. For £1,518 RV Shift tractors get snail’s pace speeds as low as 20m/hr – a simple piece of software sees it activated and with it comes a mollusc icon on the armrest. Pressing and holding the Field/Road mode button initiates creep speeds.

The transmission also includes a decent brake-to-neutral function, disengaging drive when the anchors are activated and re- engaging travel when they’re released. And because of the hydro-mechanical chemistry there’s also a hill-hold function ensuring there’s no roll-back on slopes – once the tractor has come to a standstill it won’t go anywhere without a dose of foot throttle.

Stopping power

On the braking front, 50km/hr 6Cs get a pretty comprehensive package including a hydraulic hand-brake, in-board front axle discs, brake boosters and the option of a clever engine-braking feature that uses a combination of the hydraulics and electronically-controlled visco fan. Activated via a foot button much like an exhaust brake, the system ups the CVT’s gear ratio, sets the fan to maximum draw and pressurises the spool-valves to dead-end the hydraulics. The principle is that it all works to load-up and retard the engine and slow the tractor up. Sadly, our test tractor didn’t have the right options box ticked when it went down the line so we didn’t get to try the feature out.

On the hydraulics front there are basically two options – a 90-litre/min open-centre gear-pump set-up or a 120l/min closed-centre load-sensing variable displacement arrangement. While both can have up to five rear spool-valves, the top-spec version has the option of two of those being electronically controlled. While that enables timings and flow-rates to be set, the real bonus is that they are operated via the armrest-mounted cross-lever. Set just off to one side of the gearstick, it is responsive enough to allow delicate feathering and cunningly incorporates a flick switch which can be used to shuttle between forwards and reverse or alter gear ratios – particularly handy for loader work.

Straight out of the Same shed, the cab shape will be familiar to many with experience of the roaring Treviglio tiger. It’s all put together at SDF’s Italian factory including the hybrid mechanical/ hydrostatic transmission.

Summary

We have to admit we’re a bit confused by SDF’s decision to downgrade its home-built CVT to powershift functionality but have to accept the marketing men in Treviglio Towers have a cunning plan they need a tractor to mix it up with the mainstream competition. Their engineering department have done a decent job in producing a synthesised powershift. To drive, it’s impossible to tell you’re actually sitting astride a stepless CVT. It’s a pleasant machine to operate with some canny features thrown in to boot but we would still question its existence when the TTV variant offers endless adaptability and poverty-spec, stick-shift 6Cs is still there to keep those daunted of owning a CVT.