Is 180hp from four cylinders as good as 180hp from six pots? To find out, we’ve been crunching the numbers and come to the conclusion — it all depends on …

If you’re in the market for a 120-180hp tractor there is a huge amount of choice — stepless or powershift transmission, manual or electric spools, four- or six cylinder. That’s right, most manufacturers now offer a tractor, even at the top end of this bracket, that’s the same horsepower but with two cylinders lopped off the front.

Same chassis, different engine

This naturally raises the question: ‘is it worth investing in the more expensive six-cylinder block, or will the smaller motor be the better choice for your workload?’ To address this dilemma we decided to compare two New Holland T6s that are pretty much identical in every way bar the engine, comparing them both on the test bench and in the field.

The T6.175 (four-cylinder block) and T6.180 (six-cylinder engine) both develop a maximum output of 129kW/175hp when the boost has fully kicked in. Comparing capacity stats, the T6.175 makes do with 4.5 litres, whereas the T6.180 boasts 6.7 litres — a clearly significant difference of 2.3 litres.

Our test candidates not only shared the same chassis but also the same transmission, and they were booted on identical tyres. A 2.64m wheelbase is the same for both tractors, so the argument that one is more compact than the other is out the window. However, when it came to measuring the turning circle, the T6.175 achieved 10.20m, making it slightly more manoeuvrable than the 10.50m/11.00m result of the T6.180. This was due to the slightly different front axles (Cat 3 vs Cat 4). With the two extra cylinders, the 7,070kg T6.180 scaled 320kg more than the 6,750kg T6.175. Since the gross weight for both NH models is 10,500kg, the four-cylinder tractor benefits from a larger 3,750kg payload.

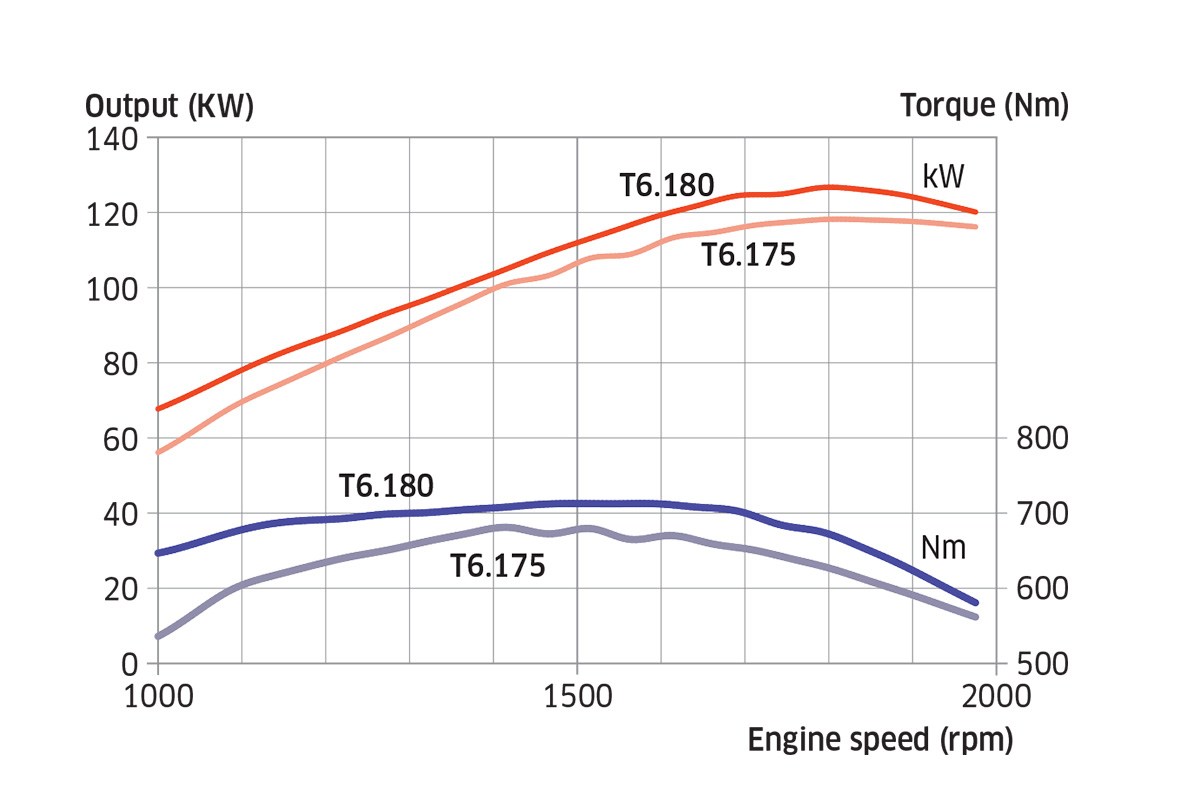

COMPARISON OF ENGINE OUTPUT AND TORQUE

Although outputs at the pto are almost exactly the same at rated speed, the different shapes to the curves clearly illustrate why the six-cylinder model appears to have more staying power at the bottom end. This is particularly the case down at 1,000 to 1,200 engine rpm.

Graph: Stefan Tovornik.

Six cylinders: More torque…

Comparing the DLG measurements from the profi tests for the T6.175 (5/2018) and the Case IH Maxxum 150 (3/2020 (which is the equivalent to the T6.180 tractor)) reveals more interesting details. On the DLG dyno, the tested tractors delivered a maximum pto output of 120.7kW/161.8hp (T6.175) and 120.2kW/161.2hp (Maxxum 150/T6.180) — very good and very similar results.

You will find more noticeable differences in the performance characteristics department. Here the six-cylinder gave an increase in torque of more than 50% as speed drops 32% and a 139% start-off torque. With the 4.5-litre, we got a torque increase of just 40% with a 27% drop in speed and a start-off torque of 110%, so it’s at a disadvantage when it comes to low-down grunt.

… but also more fuel

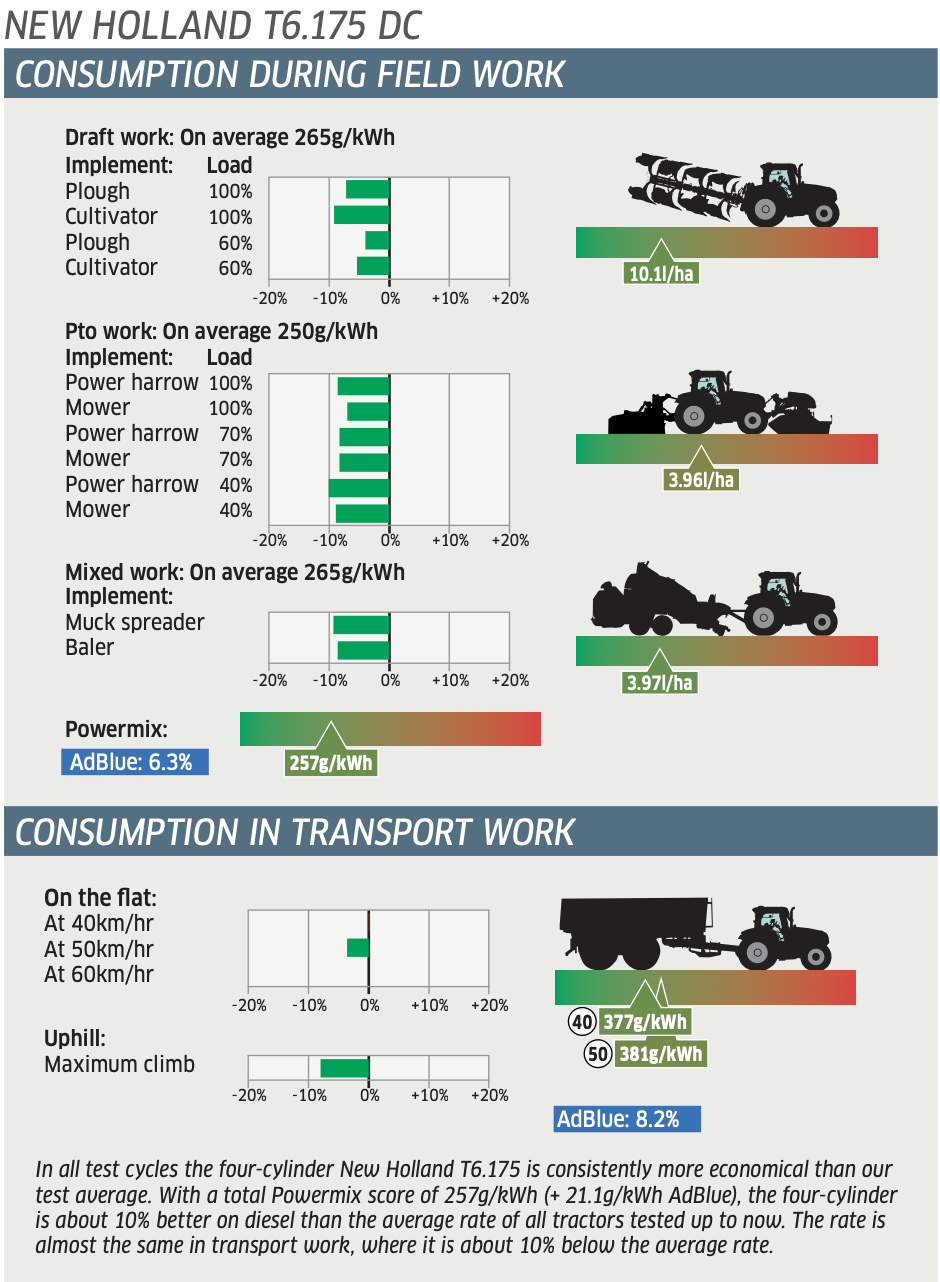

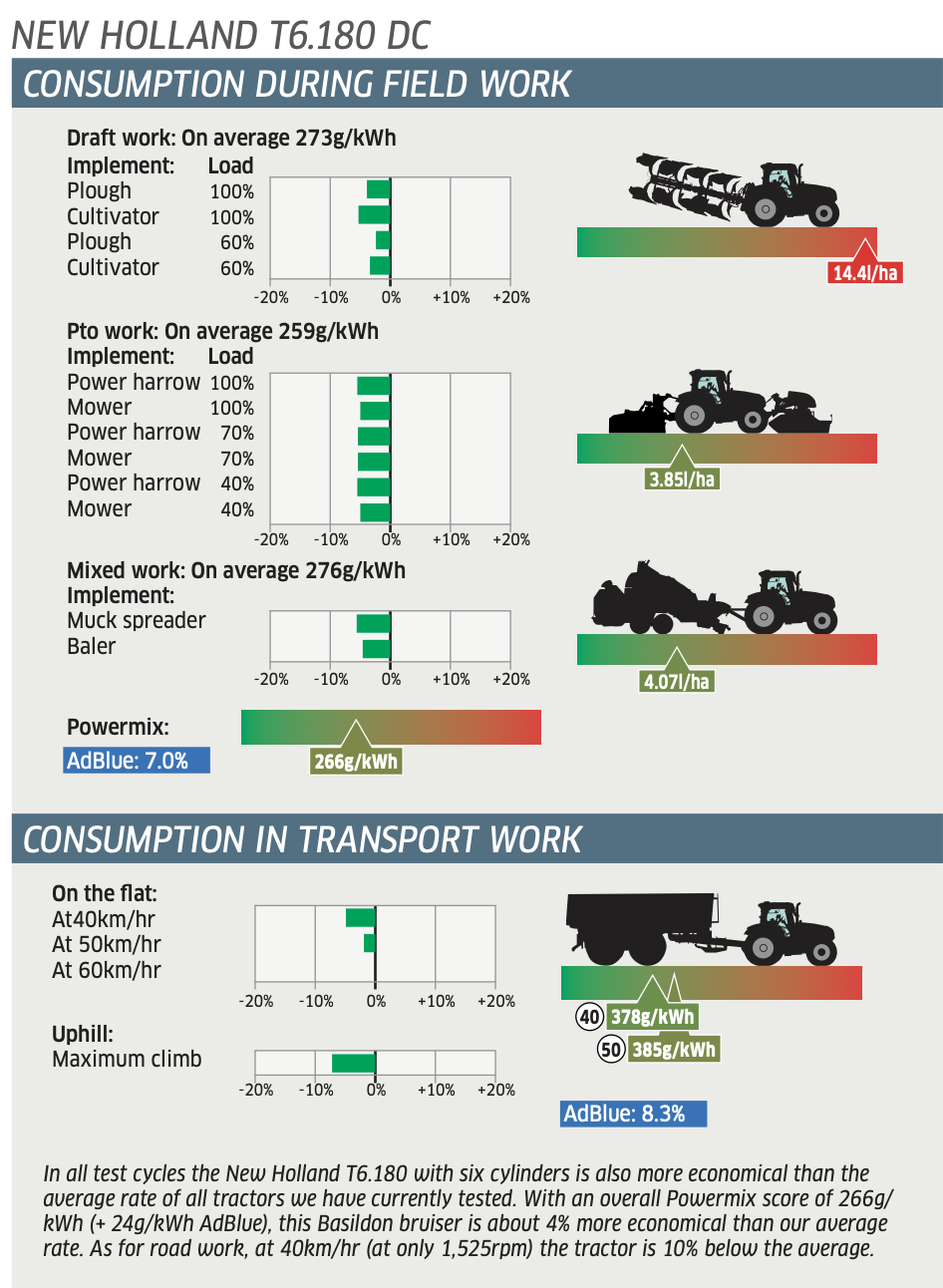

But how does the 50% larger combustion chamber count affect fuel economy. At 273g/kWh to 265g/kWh, the six-pot consumed around 3% more fuel than the four-cylinder in draft work. If these values are converted to a drawbar power of 100kW/134hp, for example, the 6.7-litre will use about 1l/hr more. Depending on the application, a four- cylinder engine can therefore save several thousand litres during its life compared to the larger motor.

Inside the cab there is no difference between the 4.5- and 6.7-litre tractors.

Consuming nearly 3% less fuel in medium to heavy pto work, the four-cylinder block demonstrated the same level of fuel economy as it did in draft work. The T6.175’s fuel economy superiority is more evident in light pto work and applications that combine draft, pto and hydraulic work. In these scenarios, the tested Maxxum 150/T6.180 would guzzle 4% more juice.

The difference is minimal for transport work. At 50km/hr, the T6.175 was exactly 1% more fuel-efficient, but at 40km/hr this stat slipped to just 0.3%.

Same gearbox

The now familiar NH Dynamic Command transmission has three ranges and eight powershift steps, features a double-clutch and has good auto functions.

It is available for both the T6.175 and T6.180 models. When combined with the different engines, the DC box provides differences in operator comfort.

It’s not just the chassis that’s the same: the rear linkage is identical on the T6.175 and T6.180. Both models are available with either a flanged or a bar axle.

For example, of the 24 forward, 24 reverse speeds, 11 are in the main field work band of 4 to 12km/hr and the large overlaps should ensure that it is possible to pull away in C1 with a trailer.

The T6.180 is able to do this even when pulling a fully loaded 26m3 slurry tanker. On the T6.175, the turbo lag of the four-pot is so noticeable that it’s necessary to drop back to the B range to get moving with the same tanker.

This results in prolonged cuts in the power flow, which significantly reduces acceleration.

On the other hand, there is hardly any difference between the two models for lighter transport work and cultivating with a higher engine speed. At 1,560rpm, the tractor hits 40km/hr, and it even reaches its maximum speed of 50km/hr, with the engine purring at just under 2,000rpm.

Nearly £2,500 extra

The basic version of the T6.175 with the 50km/hr Dynamic Command transmission is listed at £113,750 on 540, 650 tyres. For ‘just’ £2,448 more you get two more cylinders under the bonnet of the T6.180.

This is money well spent if transport and steep hills are going to account for a good chunk of your new steed’s workload — not just for the extra torque for pulling away but also the exhaust braking, which is a standard feature on the 50km/hr tractors.

But it’s not just about the extra cash you’re spending on day one, as the DLG tests show the six-pot will also be using 4% more diesel.

For lighter jobs such as raking grass, lugging a sprayer or hedge cutting, the four-cylinder is the better option as it’s less expensive and you will win on fuel consumption at tasks where the engine is only working at half load. And if you don’t have dramatic variations in soil type, the four-cylinder is still perfectly capable of performing most cultivation duties.

This article was taken from the 01/2021 issue of profi. For more up-to-date farming news and reviews click here and subscribe now to profi for just £3.99 an issue.