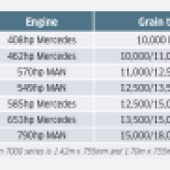

The new 8900 Lexion flagship packs 790hp, almost double the geegees of the first 480 launched 24 years ago. But it is not all about the muscle generated by the MAN engine. Like the rest of the Lexion family for the 2020 season there have been a vast number of hardware updates and at long last a logical numbering system has been introduced.

The new range consists of the 5000 (five-walker), 6000 (six-walker), 7000 (narrow body 1.42m hybrid) and 8000 (wide body1.70m hybrid). While the walker models will be available in other markets for next season, Claas UK and Ireland has decided to hold these models back until harvest 2021. Product specialist, Adam Hayward says that there is a lot of new technology in the new Lexion models, which means staff need training on service and parts to provide the level of support owners are accustomed to. Of the 18 pre-production machines being operated in the UK for this season two are walker models.

So sticking with the new hybrid models, what’s changed? The biggest difference is the APS system: the threshing drum diameter has been increased from 600mm to 755mm with 10 rasp bars instead of eight. The separation drum has grown to 600mm. Bigger drums also mean bigger concaves, with a more direct and faster crop flow reducing straw damage and smoother delivery to the two rotors. The 4D cleaning system can alter the left and right rotor flaps independently for a more even drop onto the sieves.

Grain tank capacities have been given a bump with the 8900 having the option of an 18,000 litre bin. There is also the option of a 180l/sec unloading auger which can be slowed to half rate for topping off trailers; 130l/sec is standard. Auger pivot angle has been increased from 101° to 105° to improve visibility.

A new belt drive system, similar to that used on the Jaguars has reduced the belt count by two over current models. The combines also gain the Dynamic Power system which adjusts the engine map to the current load and the ability to save fuel in doing so.

In the cab the main change has been the adoption of the Tucano’s armrest controls making it more intuitive to adjust settings. The Laser Pilot system has also shifted from the side of the header to above the cab. The newer system is said to be more precise and can even be used to follow tramlines.