More automated steering solutions are in development, but Claas is not ‘practically’ working on an autonomous tractor. Neither does it plan to make engines, but could it be working on an in-house designed CVT for larger tractors?

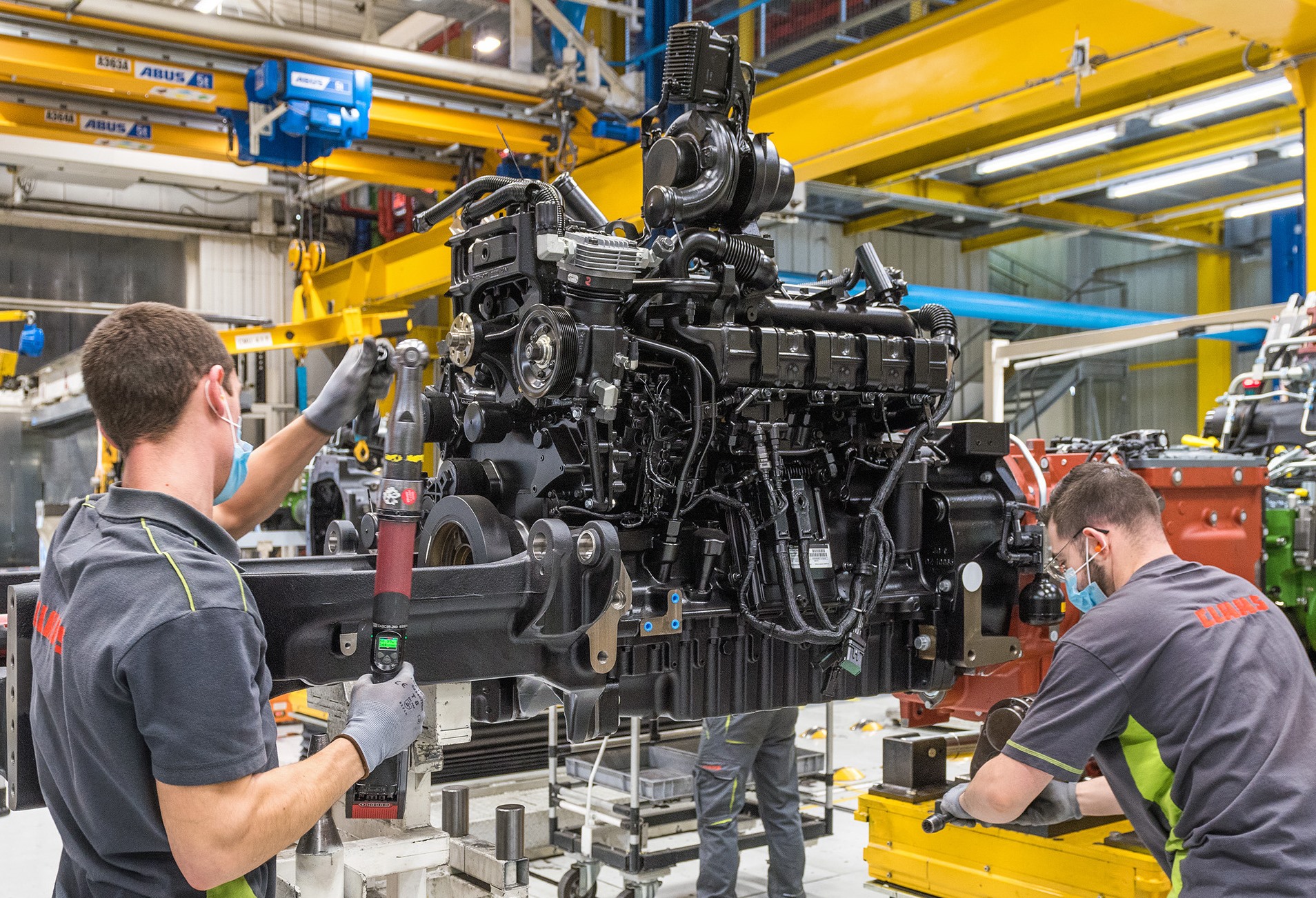

These were just some of the remarks from the Q+A session at the end of the recent online press event marking the opening of the company’s modernised tractor plant at Le Mans, France.

Some of the questions asked by journalists were about the new facility, such as the average time it takes to build a tractor (15 hours). Another was on the importance of the tractor business for the Claas Group (roughly a quarter of turnover i.e. approx. €1b).

The market share of Claas tractors in Europe was also discussed (goal is 10%), as was the most popular range made at Le Mans (Arion 400), and Germany is most important export market for the French-made tractors.

More challenging questions included one as to the effect of the current shortage of parts faced by manufacturers. Thomas Böck CEO of Claas Group confirmed the supply market is quite difficult. “Every day it affects different products, different lines and different factories,” he commented.

Fortunately, they have not had line stoppages of longer than one day, and all production time lost by supply chain problems has so far been resolved by additional working shifts. “Parts supply is affecting us but is not stopping us and we continue to deliver products on time.”

There was a question about the significant rise of raw material costs and whether this will lead to a rise in machinery prices?

Claas Group CEO Thomas Böck

“Material costs have gone through the roof, up 20% in some cases,” commented Mr Böck, who added they have no option but to raise prices to customers.

“However, we will do this moderately, and by modernising our factories we are continually improving efficiencies of production, which helps to keep the prices at a level that customers can afford.”

Alternative engines, fuels and robotics, are always popular questions at press conferences and there was one about whether Claas is involved in the development of electric engines or electrically-driven tractors?

The company has been doing this for a long time and started a pre-development programme almost 10 years ago, confirmed Mr Böck. “We are looking into different technologies, not just electric only or battery-electric. There could be some form of hybrid system available soon.”

He confirmed that Claas is also investigating gas and hydrogen powered engines, but does not envisage using some form of hydrogen combustion for at least the next 5-7 years.

“The technology is not mature and the price is too expensive for customers. What we are doing is testing the technology and looking at the benefits.”

It would seem unlikely that Claas will produce its own engines in the future? “Not making an engine allows us to go out onto the market and pick the best available solution for a tractor range,” commented Martin von Hoyningen-Huene, head of the Claas tractor unit and Group executive board member.

“If you have your own engine factory then you have to use what you have. We can provide our customers with our transmission and match it to the best available engine.”

“Lots of other combustion systems or electrical drives are coming,” added Mr Böck. “We are very flexible to change whereas if we would have had an engine factory then we would not be able to change so quickly.”

Claas was in the news recently following the acquisition of a minority investment in AgXeed, the Dutch developer of the autonomous platform.

Will AgXeed autonomous tractors be built in Le Mans? “No”, said Mr Böck, “but we are interested in collaborating with the technology. There could be synergies between our electronics and their control systems, but it is an independent company and we only have a minority share. What we are doing is developing technology together and we can use our distribution channel later on when the product is ready for a bigger market.”

The Claas Group CEO also took the question about more autonomy in the future and confirmed the company is developing the next generation of autonomous steering system.

“Autonomous in that we have the tracks and we can follow them,” he commented. However, he stressed that it is not a full autonomous tractor that is like a robot.

“We will come with a lot of new driver assistance features integrated into CEMOS. This is how we see tractor progress for the next few years and we have no plan to have a robot anytime soon.”

The final question was about CVTs. The Cmatic transmission in the Arion 500 and 600 models was developed and built in-house. The question was does Claas have any plans to develop an in-house CVT for other tractor ranges?

“We are very proud of this transmission and you can imagine this is something we are thinking about,” commented Mr von Hoyningen-Huene.