As a fertiliser spreader empties, the weight distribution also changes. Which will make a difference to the angle of the discs and, in turn, the spreading pattern can suffer. Agco’s clever top link can self-adjust to keep the outfit on the level

KEEPING IT BRIEF

- Smart Toplink is compatible with Fendt, Massey Ferguson and Valtra tractors.

- It ensures that a mounted spreader remains at a level position as it empties.

- This is reckoned to prevent yield losses due to uneven application.

According to Valtra, up to £17.50/ha can be saved with the new Smart Toplink. While the exact amount is debatable, the logic is very simple to understand. The farmer attaches the fertiliser spreader, fills it up, sets it to the recommended height and lengthens the top link to the required angle.

As the amount of fertiliser in the hopper reduces, the weight applied to the rear of the tractor also reduces, resulting in the critical angle of the spreading discs tilting increasingly upwards. Various studies say this leads to a change in the distribution across working width, the application rate shifting from the centre to the outside.

If you use the DLG test procedure as a reference, it states that the coefficient of variation of lateral distribution should not exceed 15%. According to another study by fertiliser manufacturer Yara, an increase in the coefficient of variation by more than 10% to 34% translates into yield losses of 3% on average. This loss rate can be either lower or higher depending on how nitrogen-sensitive the soil and the crop are.

The Yara study also shows that optimum distribution is only one of many factors that influence yields, but, unlike the weather and type of soil, you can ensure that fertiliser is applied as accurately as possible.

Today, Smart Toplink will not change any of the spreader’s settings; you still need to ensure these are precisely set. Yet it does ensure that the spreader maintains the correct disc angle as it goes from full to empty, and the bigger the hopper, the more important this will be.

Simple hardware

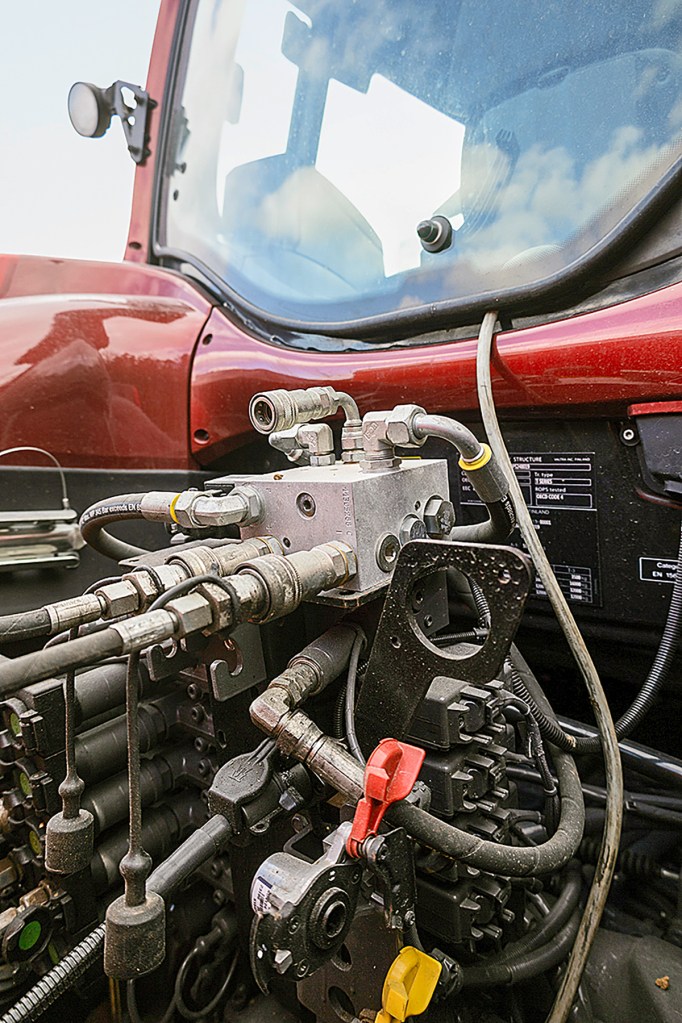

The actual hydraulic top link is no different to your standard off-the-shelf item. The brains are all contained within the small black box that houses the ECU.

This box takes information on the current ground clearance from two radar sensors, which are mounted in front of and behind the spreading disc. The information is then used to determine the current spreading angle and decide whether a correction is necessary. The ECU will then send across a command to an additional hydraulic valve, which is supplied with oil by the tractor’s load-sensing system. The top link is linked to this extra valve block, which, in turn, extends or shortens the piston.

Downside of the design is that the top link can only be manually extended or retracted using the two buttons on the Smart Toplink page on the tractor’s screen rather than directly off the spool valve.

This isn’t a big problem when tilting the fertiliser spreader backwards when loading the hopper; however, not being able to use the external buttons on the mudguards can be a pain in the neck.

Retrofit solutions preferred

Because Smart Toplink is a retrofit solution, the ECU and the hydraulic valve are not integrated into the tractor.

The new system can be fitted to all ISObus-compatible Agco tractors (namely Fendt, Massey Ferguson and Valtra), although it cannot be fitted in the factory as of yet; this is not something Agco has ruled out for the future. It could also prove to be useful for tillage equipment, but time will tell on that one.

Another advantage of the retrofit concept is that Smart Toplink is compatible with any mounted broadcaster. It is just a matter of attaching the radar sensors, which can be done to any age of machine.

Logical cab controls

Operation is via ISObus, although there is not actually much to operate.

Essentially you enable the system at the touch of a button and then the rest is done automatically. The only setting you need to enter — apart from calibrating — is the target angle, which can be up to 4°, for instance, for a late application.

Once activated, the system is not overly trigger happy, so to speak, when it comes to making all the necessary adjustments. Although the sensors measure the current ground clearance several times per second, the system doesn’t respond at the same rate. Valtra adds that an overly sensitive system is actually not helpful and brings very little benefit.

In the field

We used the new system when applying fertiliser to wheat and barley fields in the spring. The Rauch spreader was on a Valtra T Series. The system had already been installed by a local workshop. In the field, it worked reliably, true to the adage ‘Switch and forget’. The operator only needs the ISObus screen to activate the system and can then go back to the fertiliser spreader page while the system is working.

After a few metres, the sensors detect the position of the spreader, and the system begins to align the hopper horizontally — quickly but smoothly.

Important note: the system is designed for arable land and grassland. It cannot cope with gravel or tarmac, as these surfaces are level in the first place. For safety reasons, the system switches off automatically at 25km/hr.

Summary

Agco quotes a kit price of around £4,270. With a saving of £17.50/ha, the investment would pay for itself after 210ha. That’s the theory. In reality, you have to do your own individual calculation, and some will decide it is just not for them. In any case, it marks yet another step towards fully autonomous machines. After all, in unmanned cabs such systems are needed to maintain the quality of work.

Andreas Holzhammer

For more up-to-date farming news click here and subscribe now to profi and save.