Over the past eight years, Agriweld has grown its cultivator range with a number of compaction-busting soil looseners in various configurations. The Min-Dis is one of those machines that utilises the minimal disturbance legs. Read on to find out more.

KEEPING IT BRIEF

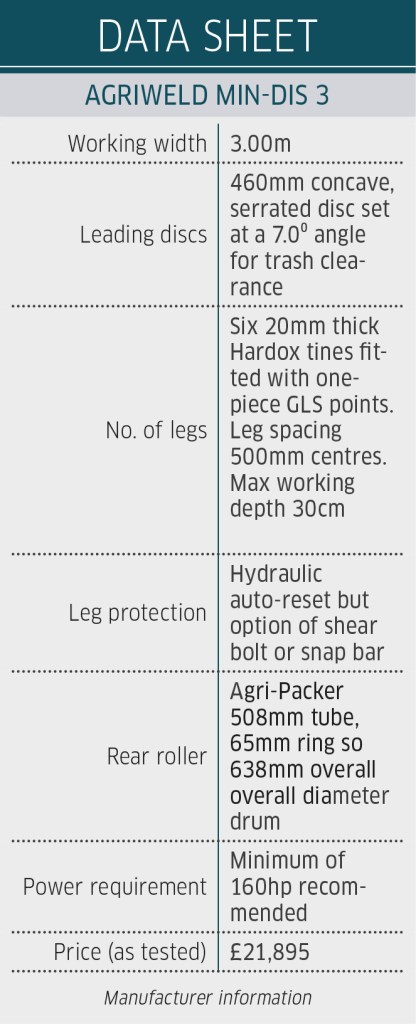

- Leading disc runs at an angle to help clear more trash away from leg.

- Arable model range from 3.0m to 6.0m wide while grassland models are from 2.5m.

- Price for the auto-reset six Min-Dis featured here is £21,895.

Sometimes our driving impression articles are rigorously planned; other times we just happen to stumble upon a machine in a dealer’s yard that we think looks an interesting tool. This is one of those occasions, having seen the Agriweld Min-Dis outside the door of Irish distributor, Cooney Furlong Machinery.

Over the past eight or so years, Agriweld has been honing its compaction alleviating minimum disturbance leg design, so it now has a broad variety of pan-busting tools to suit different scenarios. These include the following:

- Mantis: front-mounted soil loosener.

- Assist: rear-mounted, positioned between the tractor and cultivator. Also available as the ASL, which previously lacked the Assist’s leading discs, making it closer coupled. This is now available with row cleaners.

- Prevent: Another variation on the Assist, but aimed at removing wheelings while also towing a trailed cultivator.

- Min-Dis: A standalone low disturbance subsoiler complete with leading discs and rear packer.

- Min-Disc: Adds two rows of cultivating discs after the tines.

- Multi-Till: a low disturbance all-in-one cultivator.

So, you now get the picture. The Yorkshire engineering business has worked hard on getting its leg assembly in order and has been able to create machines that its farming customers have asked for.

Although it has mechanical shear bolt and snap-bar leg protection options, around 85 per cent of its subsoiling machines are now going out with hydraulic auto-reset. Indeed, the ideas man behind the drawing board, Dean Foster, adds that the extra cost is no longer seen as the sticking point it once was, and that’s true even in areas where metal snapping aggregate is not in abundance. The reason is twofold: the additional cost is not as eye watering as it once was as overall machine prices have increased; and the gains in output by not having to stop and replace a shear-bolt.

What are we looking at?

As mentioned, our focus is on the minimum disturbance Min-Dis subsoiler. Like the other Agriweld machines that employ the same leg, the objective is not to bring large clods to the surface. The maximum working depth is around 30cm, but, if you want more earth shattering to a greater depth, then flick forward a few more pages in the Agriweld price list and look at the full-fat subsoiler.

Alternatively, if you’re happy with the Min-Dis depth, the company has developed an adapter that allows the usual low disturbance GLS point to be swapped for a Trio point that will give more soil mixing. If you are thinking for a moment, ‘hang on aren’t those Sumo points’, then you are correct. Rather than trying to reinvent the wheel, Dean says that these wearing items are widely available from several sources that will make them out of conventional metal or material with longer life attributes. This means Agriweld customers benefit from greater choice than if the bits were made in-house.

From the front

Starting at the headstock, this is a Cat III set-up leading to a chunky frame predominantly fabricated from 150×150 box, which is either 8mm or 10mm depending on its function.

There’s a cut plate for the removed hydraulic pipes and seven-pin plug to slot into when the machine is parked up. Likewise, there are parking stands at the rear for supporting the unhitched machine.

The leading discs have what Agriweld calls its ODS (Oblique Disc System) as a means of clearing trash away from the path of the following leg so it doesn’t snag and create lumps.

The disc itself is a 460mm serrated concave disc running on maintenance-free bearings. Critical to this is the 7.0 degree angle of the disc arm for that path clearing task. Each arm is clamped to the frame, with rubber cord sausages allowing some stone hopping protective give.

For arable work, having the disc perfectly aligned with the tine is less of an issue than it is in grassland. However, for our pasture job, a little bit of fine tuning, and we had everything running inline and the disc was doing a good job of chopping through the sod, preventing it from being lifted and pushed to the side by the tine. However, if all your work is in grassland, then Agriweld does offer a straight, vertical disc. In an arable setting this can hairpin straw, and, once it has lost its sharp cutting edge, it’s less effective than the ODS arrangement.

An equal amount of thought has gone into setting the depth of the disc. Turnbuckles, on either side, pivot the disc carrying beam in and out to get the ideal setting.

Leg chat

As mentioned, the legs on the Min-Dis are a minimum disturbance design made from 20mm thick Hardox steel. These have the quick and easy to fit Sumo GLS point. Or with Agriweld’s pointer adapter, they can also be used with a wider, more aggressive Trio one- piece foot for bringing a bit more soil to the surface if that’s what you’re seeking.

Our 3.0m wide machine was equipped with six tines on 500mm centres. The legs are offset 350mm from their neighbour. These were protected by the hydraulic auto-reset system that adds around £3,900 over the price of a shear bolt model.

There are three accumulators that allow the legs to trip, with the operating pressure shown on a gauge on the right. You can tailor the pressure to your ground by opening and closing a valve. This allows you to pressurise the system when you get to the field from the spool valve; the only problem is that the pressure gauge was hidden by the mudguard of the Puma. We would prefer to see it in a more central location just so you can check that a leaky spool has not let the pressure drop.

Stone protection is not the only benefit of the auto-reset system. You can also use it to retract the legs when in transport and also when the machine is removed when it then rests on the roller and discs; if you leave the legs lowered, then the parking stands also need to be down so it remains balanced. The retract function is also advantageous in reducing the transport width of the larger semi-mounted models.

Rolling this way

Our machine had Agriweld’s Agri Packer, a shouldered ring arrangement that’s a hefty weight. How this is fabricated has recently been changed. The shouldered rings have more of a profile that makes them sit 15mm farther away from the drum than on the previous version. Dean says that this helps the rings press against the soil rather than relying on the drum to do the majority of the consolidation. In our grassland scenario this was not something we could test.

Speaking of grassland, there is the option of having a plain roller, with drive teeth as a cheaper alternative.

Back to the Agri Packer, and here again there is another neat feature, this time with the scraper bar. By pulling a pin on either side and using the supplied tool you can swing the scrapers away from the roller, allowing any stubble, soil and more crucially seeds to fall away when cleaning — excellent from a field hygiene perspective. In the very dry conditions we were using the Min-Dis it also had the benefit of being able to take the scrapers out of work and thus prevent any unnecessary wear, a second hole for the pins keeping the bar in its secondary position.

One last point, the roller uses bolt-in stub axles, so, if it does happen to get damaged after a failed bearing, it is a much quicker and easier task to replace than having to cut out and weld.

Summary

Min-Dis may not be designed as a grassland subsoiler, but, as we found out, it is certainly capable of running through a sward without damaging it. You can see how the leading discs do their job of not just cutting through trash but also clearing a path for the tine to do its job in stubble and cover crops. The leg auto-reset was working its magic, allowing us to keep moving in stony conditons.

Looking around the machine, you notice great attention to detail, such as the laser- cut frame where the wiring for the lights can be secured and how the scraper bar can be quickly flipped to enable easier cleaning.

Mervyn Bailey

For more up-to-date farming news click here and subscribe now to profi and save.