Depending on the amount of slurry and soil moisture, a rear roller on a disc harrow is a potential sticking point. Amazone can now fit a following harrow on its Catros+ disc cultivator when working with slurry and digestate.

KEEPING IT BRIEF

- The Pro version of the Catros+ disc harrow comes slurry-ready from the Amazone factory.

- Slurry is applied behind the first row of discs.

- Double tines are an alternative to the rear roller.

- The tines shift the centre of gravity closer to the tanker and reduce the weight by 260kg.

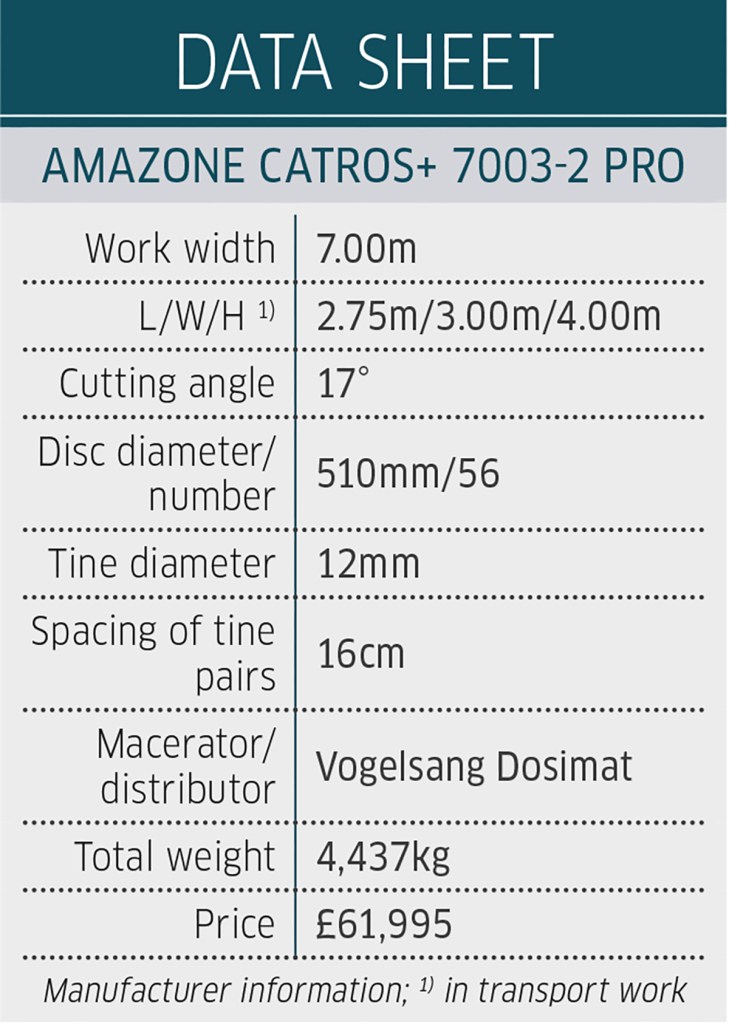

There are several variations of Catros in the Amazone disc harrow range. Newest addition off the rank is the Pro, which is pitched at farmers and contractors wanting an off-the-peg slurry- incorporating cultivator from the factory. It comes in working widths of 5.0m, 6.0m and 7.0m. Vogelsang supplies the macerator/distributor for these mounted units, which also benefit from special disc bearings to better match the corrosive nature of slurry.

Less weight

Last year, we went to see a Catros+ 7003-2 Pro in action with German farming business Althausen Agrarservice, in the Rhineland region, working down cereal stubble ahead of oilseed rape. The 7.0m wide disc harrow was mounted on a Kumm 16m³ tanker. The farm opted for the double following harrow, which allows it to evenly distribute chopped straw and still do a clean job even in wet conditions.

Is the disc harrow without a roller lighter? Yes, but not by that much. A clean Catros+ weighs in at 4,437kg with the double row following harrow, compared to 4,700kg with the 60cm cage roller. A difference of just 260kg, according to the Amazone brochure stats.

The weight advantage is more noticeable when working in the field: although the lighter harrow needs some additional gauge wheels at the front, to control the depth, the centre of gravity is significantly closer to the tanker’s axle. Another advantage is that the soil and slurry don’t stick to the harrow like they do with a roller, which then needs extra lifting power.

In the front row

The slurry disc harrow will definitely get dirty. On the machine we visited, the slurry was still being applied in front of the first row of discs. However, not just in our own experience, but also that of users, placing the slurry in the shadow of the first row of discs is becoming more popular. Amazone has actually stopped selling the version where slurry is applied ahead of the first gang of Catros discs this year.

The 50mm diameter hoses are tidily routed and never kink — not even during folding. Spring-loaded chains on hose packs help with this task. Speaking of folding, when the 7.0m harrow is in its transport position, in order for it to sit below the 4.0m road going height in certain markets, ground clearance is not abundant. You do need to watch out that the inner tines do not catch the ground.

Twist the discs

As mentioned, the Catros+ Pro rests on two solid 31×15.5-15 wheels at the front end. The hydraulic cylinders on the gauge wheels are only needed for transport in the folded position (the wheels move outwards to avoid colliding with the tank). This is also the reason why the disc harrow with gauge wheels is only available on the 6.0m and 7.0 models.

Disc depth is controlled by Amazone’s Smart Frame — where the disc arm beam rotates to lower the discs. Once the machine is fully aligned, depth is precisely adjusted without causing any sideways pull — great!

The 510mm diameter scalloped discs on a 12.5cm spacing ensure an intensive mixing action. As usual, the individual discs are mounted on rubber sausages for overload protection. We were working at about 8cm to make sure that the slurry was thoroughly incorporated. Going shallower may improve volunteer establishment but can also leave the odd lump of straw on the surface.

The following two rows of tines levelled the soil nicely. Only long-ish straw stalks tend to get stuck in the 12mm thick, 42cm long tines — as happened on our test field headland. Tine pressure can be altered by adjusting the angle and contact pressure, which is done using a pin-and-hole arrangement.

Other details

- There is the extra-cost option of central greasing.

- Amazone has redesigned the oil-filled, maintenance-free bearings. The chrome content of the mechanical seals has been increased to prevent them from rusting.

- Larger working widths are available on the 8.0m+ models which come under the semi-mounted TX.

- A 200-litre Greendrill break crop seeder is also on the list of options.

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.