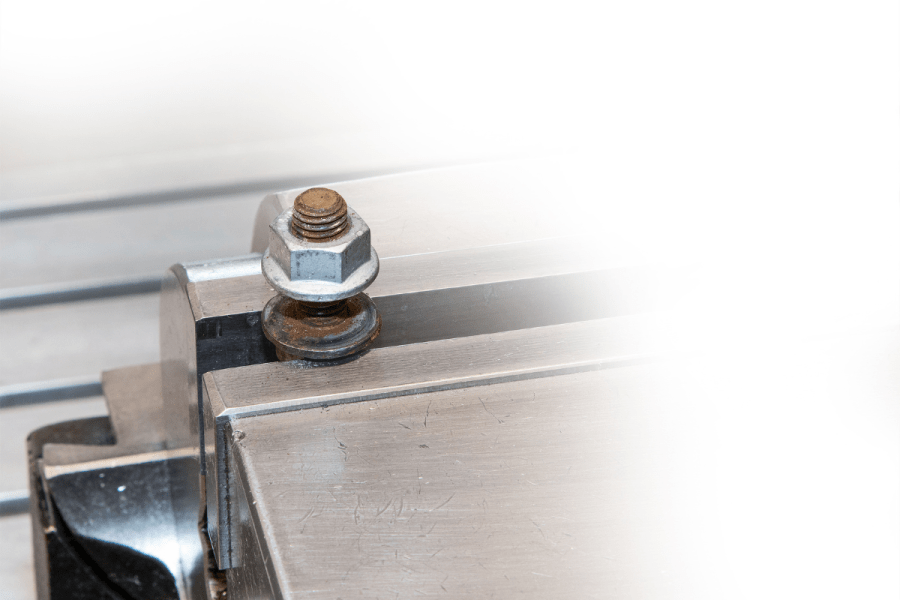

WORKSHOP: If the threads on bolts or studs are dirty, rusted, damaged or even painted over, repairs can be quite a challenge. The TrimNut repair nut aims to help.

Baier and Michels is part of the Würth Group and specialises in making bolts for the automotive industry (see “Bolt production at Baier and Michels” for more information). The manufacturer previously developed so-called thread-cutting bolts that can be used to cut threads into drilled holes or remove dirt and paint residues from internal threads, made possible by modifying the threading. The bolts have a slightly conical form where the cross section of the thread progressively increases. The closer you get to the head of the bolt, the higher the pitch of the threading. As such, the bolt gradually cuts the thread — similar to a tap. The TrimNut works the other way round: the nut is designed to recut damaged threads and remove dirt.

How it works

When threading out a traditional bolt from its hole, it often squares up with the threading in the hole. Also, metal shavings and dirt may clog the bolt, causing it to seize. In the worst case, the bolt will break off. To prevent this, the hole in TrimNut has a trilobular shape. This means that it is shaped liked a rounded triangle. As a result, the pitch is higher on the flanks than in the rounded tips.

For more up-to-date farming news click here and subscribe now to profi and save.