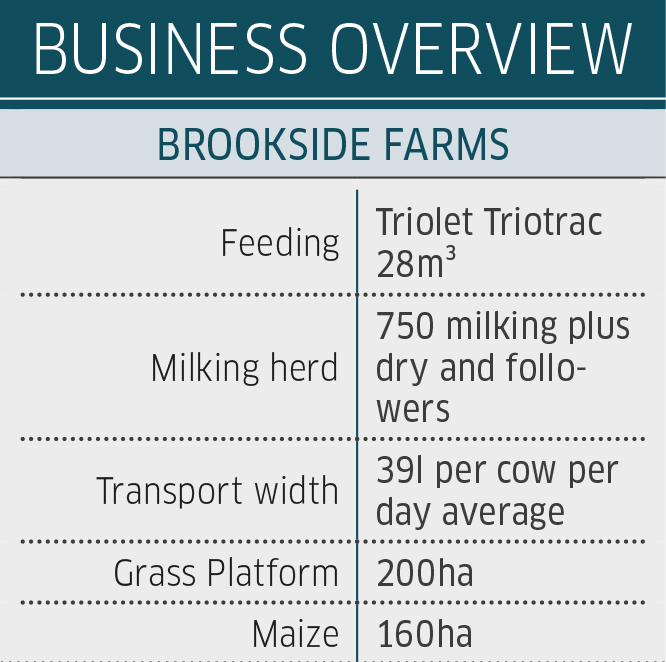

Brookside Farming took delivery of their self-propelled feeder in April 2025. It has been delivering daily rations for 750 cows since, bringing increased efficiency and consistency with the aid of AI driven ration prescription.

KEEPING IT BRIEF

- Farm turns to Trioliet for a self-propelled feeder, adding precision to the ration

- The farm has adopted an Ai driven system to gain efficiencies in feed prep

- Animal health and silage clamp presentation see an upward trend

Over nearly fifteen years, Brookside Farming has transitioned from a low-input New Zealand style setup to a high-input, high-output herd. Located outside Chester, on the edge of the Cheshire and North Wales border, the herd varies from 850 to 900 cows, with between 740 and 750 milking at any one time.

“The investment we’ve put into the farm drove the change, it’s a productive space, and needed the approach to match,” points out owner, Peter Cope.

As part of its move to higher yielding cows, the farm has been using World Wide Sires throughout to shape the Holstein Friesian base herd to an efficient genetic line that has resilient health, good breeding and high milk yield,” that Peter is happy with.

Heifer replacements are contract reared off-site due to space limitations on the home farm. This off-farm rearing strategy frees up critical infrastructure and manpower for the milking herd while still maintaining good genetic development and herd continuity. The herd is on a 25-30% replacement cycle, this equates to about 240 fresh heifers entering production each year, replacing older animals, as well as cows that have a low yield record.

The milking herd is permanently housed in a barn designed around a flood wash system, which keeps passageways clean without any scraping system. Cows are bedded on sand that settles-out of the washings enroute to a separator system, sand is mixed with manure and deployed to the land.

Once per day

Feeding takes place once a day, beginning at around 5:00am and thanks to the yard layout, operators can access passages without having to move cows. One compromise of the power flush system is the trough at each end of the shed, which prevents the use of automated silage pushing robots. There would need to be four or five pushing robots, which would be prohibitively expensive compared to the Ford 333 tractor that normally pushes up the feed four times per day.

Silage is harvested on a four-week cycle on a 200 hectare grass platform, with two cuts already completed by the start of June and a third scheduled for later in the month. The local soil is quite heavy and retains moisture well. Grass lays are reseeded every three years, but there are a number of meadows that are often one year leys due to flooding, while they grow grass; even in dry times when they do flood, the subsequent weed burden is intolerable in a multicut system.

The farm also grows 160 hectares of maize for its ration, which is grown close to the farm, on land away from the flood plain. Brookside buys in straw along with the other elements of the TMR. To maintain quality and nutritional consistency.

Silage harvest is split between farm equipment and a local contractor who comes in with a self-propelled forager. The farm tends to take care of mowing and buckraking. Clamping is done with a tractor and front mounted buckrake, Peter also hauls a compactor behind, which although needs more ponies to push the grass, it does save time rolling, with a notable decrease in waste making it very much worthwhile.

Feeding Evolution

Brookside’s journey with self-propelled feeders has had its challenges. Fifteen years ago, a used RMH self-propelled feeder was purchased at a farm dispersal. Unfortunately, it came with wear-related issues, leading to significant maintenance concerns. And a “I’ll never have a self-propelled machine again mentality.” from Peter.

Twelve years on, circumstances changed. When the farm’s trailed Trioliet feeder was due for replacement, allow hours used Keenan self-propelled tub mixer became available. It was a practical next step with immediate availability and a manageable price point. However, the Keenan’s 25m³ capacity and a 10-tonne weight limit meant it required more fills than anticipated. While a 25m³ tub typically suggests loads of 12-13 tonnes, this was not achievable within its limits. This meant extra time and fuel per day, not to mention extra wear from higher trip counts.

Other self-propelled machines were looked at, with Siloking a front runner, but most of the machines in the offing shared a similar concept for milling the fodder out of the clamp. Peter was convinced the cutting head of the Trioliet would deliver a marked improvement in clamp management.

Eventually, the farm revisited the Dutch built machine, having previously run trailed models and visited the factory, they felt confident that the brand could deliver a suitable self-propelled solution. The dealer relationship also contributed to the decision. Given the importance of backup and parts availability, a strong support network was a deciding factor.

Herd Management and Feeding

Brookside’s herd is divided into six groups: highs, mediums, lows, freshcalved,heifers and dry cows. Milking is performed three times daily, and the herd averages 39 litres per cow, per day. High-yield cows receive a 70.5kg as-fed ration with 30.1kg of dry matter.

This drops incrementally through the feed groups to 56.6kg as fed ration with 24.6 dry matter for the low yield group. The constituent parts of the ration also change fractionally, with different cuts of grass silage volumes used group depending.

The Triotrac X in Action

Brookside chose a 28m³ Triotrac X, although this model can go up to 32m³. The machine is substantial, with three axles, two of which are driven, and all are steerable. JCB components are used for the drive axles. Hydraulic suspension supports the chassis and lowers the front for loading.

A 6.7-litre FPT engine powers the machine. It is mounted on rails, allowing it to slide out to the side for servicing after removing a single exhaust clamp. The transmission is hydrostatic over powershift, which supports slow, precise operation during feeding and efficient transport up to 40km/hr.

Initial experience shows fuel consumption to be favourable. With just one machine running for feeding, the Triolet is using close to 70 litres of fuel per day. The other side effect is the longevity of the farm’s loaders – there are two JCB TM320S pivot-steer machines on the farm that are ousted every five years. With north of 500 hours a year saved, their running costs have been lowered, and the shear grab is only kept for emergencies, another piece of equipment saved.

Smarter Ration Control

Brookside adopted the Algo Milk system last year to enhance ration management. While a nutritionist remains involved, the system provides day-to-day decision guidance. Integrated with the Dairy Comp interface, Algo Milk uses milk yield data to inform cow grouping and ration volume.

As cows move through their lactation cycles, the system highlights changes in margin related to feed intake and suggests optimal group transitions for each animal. It also calculates ration costs, monitors forage quality changes, and can serve as a feed inventory if input data is accurate.

There are automated segregation gates that could allow the system to sort cows into groups, but decisions remain with the farm staff, who assess the full context behind changes in milk yield. Currently, the priority is using the data as a management prompt, not as a fully automated directive. Algo Milk’s real strength lies in marginal cost control. When feed prices spike, the system helps Brookside evaluate where feed efficiencies can be gained with minimal compromise to production.

The CowManager platform is also in use, operating independently from Algo Milk. It provides real-time cow status data—temperature, movement, and behaviour (eating or resting). However, integration between the systems is currently lacking, meaning health issues must be identified separately from yield-based metrics.

CowManager excels in identifying abrupt changes such as elevated temperature or inactivity, for events like early mastitis or silent heats, the system’s alerts are extremely useful. The team on the farm all have access to the system on mobile devices.

Feeding Routine

Brookside typically prepares seven loads per day: one each for high, medium, and low-yielding cows, one for dry cows, the fresh group and heifers; and a pre-mix for the following day. The full routine takes around three hours and is rotated among three operators: Josh Kerr (five-day shift), Maciej (seven-day shift), and Peter Cope (every other weekend). This schedule maintains consistency and operator familiarity.

Loading for the high-yield group takes about 20 minutes, often amounting to 14 tonnes. A portion of the previous day’s premix is left in the tub overnight to speed up the next morning’s start.

The Trioliet’s cutting system sets it apart. While most competitors use rotating milling heads with blades, Trioliet’s design features a reciprocating blade backed by a rotor that breaks up fodder. Peter notes that it has resulted in a cleaner silage face, reducing waste reducing water ingress and so aiding consistency.

The default cutting profile follows a 400mm deep j-curve, starting from the top of the clamp and sweeping downwards and out toward the machine. This leaves a near-vertical silage face and prevents overhang at the top, even on tall clamps up to 8.0m high. This was a feature that quickly became noticed as a clamp safety benefit.

“Some machines leave a curved face which, on high faces leaves a significant enough overhang to be of concern when people are up there pulling sheets back, the Trioliet doesn’t do that,” explains Peter.

Although not all fodder lands perfectly on the conveyor during cutting, over-spill is managed either immediately or during loading for later groups. Operators use the blade and conveyor together to gather and load excess material from the clamp floor. There are two schools of thought on the clean-up, Peter will do this as he loads each mix, whereas Josh leaves it to the end, and gives the sweepings to the low yield group, or dry cows.

Loading profiles can be set for different fodder types, adjusting depth and speed. While clamped feeds (maize or grass) use similar settings, straw—processed using a RotoGrind—benefits from a larger bite and extended cutter head reach.

Loading pre-mix involves lowering the fixed blade and pushing into the pile, finishing with a brushing motion to clean up. It’s not a perfect clean up but is comparable to other self-propelled machines.

For the premix there are a couple of hundred kilos of concentrates and minerals, which highlight the small side door on the tub somewhat useless, it’s above shoulder height for most humans, and is only about 150mm wide which would make adding the 20kg bags a slow laborious job, so a loader is needed, but only once per day.

The weighing system is independent of the chassis and loading element, but does have an operational quirk, in that the chassis needs to be level to get an accurate weight reading. this manifests as a 30 second wait when doing a large load as the already loaded ration needs to level out in the tub before a stable reading is seen.

Results can vary by 50-100kg depending on how large the load is, the trick is to switch off the loading conveyor as you reach target and then use what’s left on the blade and conveyor to top off the ration weight.

Getting around

Despite its size, the Trioliet is notably manoeuvrable. It operates primarily in all-wheel steer mode. The centre axle turns less sharply to minimise tyre wear, only scrubbing slightly at full lock when in crab steer mode. This crab steer function proves helpful in tight areas, such as when manoeuvring around the water and syrup towers, as well as moving away from clamp walls.

There is a joystick steering feature, which caught one of the operators out one day, gathering the first battle scar to the rear light strip/bumper. The joystick mode was accidentally engaged and as dispensing began the lever was knocked which swung the rear end into the feed barrier.

Summary

Brookside Farming’s decision to stick with a self-propelled feed and invest in the Triotrac X has paid off with notable gains in feeding precision, labour efficiency, and increased milk yield. The integration of advanced management systems like Algo Milk and CowManager supports the farm’s commitment to data-driven decision-making.

The real-world gains have been measurable, with a significant reduction in stomach twists through consistency and having the feed at the barrier when the cows exit the parlour, the farm is now at 0-1 instances per month, rather than 1-2.

Improved clamp management has also been a welcome side effect, cutting the fodder rather than tearing it leaves the face tidy and tight reducing climatic impact. Getting across the whole face of each clamp more frequently has also aided feed consistency.

In an industry increasingly focused on margin control, animal health monitoring, and labour optimisation, Brookside’s setup demonstrates how machine choice and digital integration can combine toward greater efficiency and increased animal health.

Ken Topham

For more up-to-date farming news click here and subscribe now to profi and save.