For some time, BvL has offered a straw blower attachment for its diet feeders. We looked into the benefits of this two-in-one machine and why it requires a tractor with less than 100hp.

KEEPING IT BRIEF

- BvL diet mixers have the option of a straw blower for bedding barns.

- This combination can help save time.

- Spreading straw after feeding helps remove metal-eating acid from the tub walls, reducing corrosion.

So, which is the best way to spread straw when bedding up? In addition to mainstream mounted and trailed machines, new robotic bedders are starting to gain popularity with livestock farmers in some countries. But what if you have several cattle barns to bed down, if cleanliness on the farm is important or you want to minimise the number of tractors on the farm?

You could opt for a straw blower mounted on a diet feeder — not a particularly common sight, but, on closer inspection, it’s a good alternative to the previously mentioned systems. That’s our team’s conclusion after scrutinising BvL’s V-Comfort Turbo straw blower.

Powerful throw

The blower can achieve throughputs of around 300kg of straw per minute, throwing it distances of 12 to 18 metres in its main stream and up to 24 metres in the side-stream. This should be sufficient for most mixed/livestock farms.

Like most conventional straw blowers, a flap on the end of the spout is used for altering the spreading distance and direction. The standard tower measures 2.52m high for entering low building doorways, but BvL also offers options of a taller tower as well as a swivelling chute that can be hydraulically rotated through 190⁰.

Getting that material moving is a 1.46m diameter turbine. On its front are vanes that not only generate a large amount of airflow but also ensure a consistent flow of material regardless of how full the turbine is. The turbine also creates a suction effect to suck in straw from the feed channel to maximise performance.

On the back of the flywheel are the throwing vanes/paddles, similar to those on a forager flywheel. Any straw chopping has to be done in the tub with the auger and stationary knives before you start bedding down, as there are no means of fitting knives in the straw blower attachment.

Gentle start-up

The straw blower is driven mechanically by the tractor’s 540rpm pto, which through the right-angled gearbox ramps up the speed of the turbine to a maximum of 810rpm. BvL says the minimum tractor power is 70hp.

To help protect the tractor’s pto clutch when starting the turbine, there’s BvL’s soft-start option. This features a mechanically driven hydraulic motor that helps to overcome the high start-off torque required to get the turbine moving with relatively low-powered tractors. Once the turbine is up to speed, the hydraulic motor is duly disengaged, and it is driven directly by the pto.

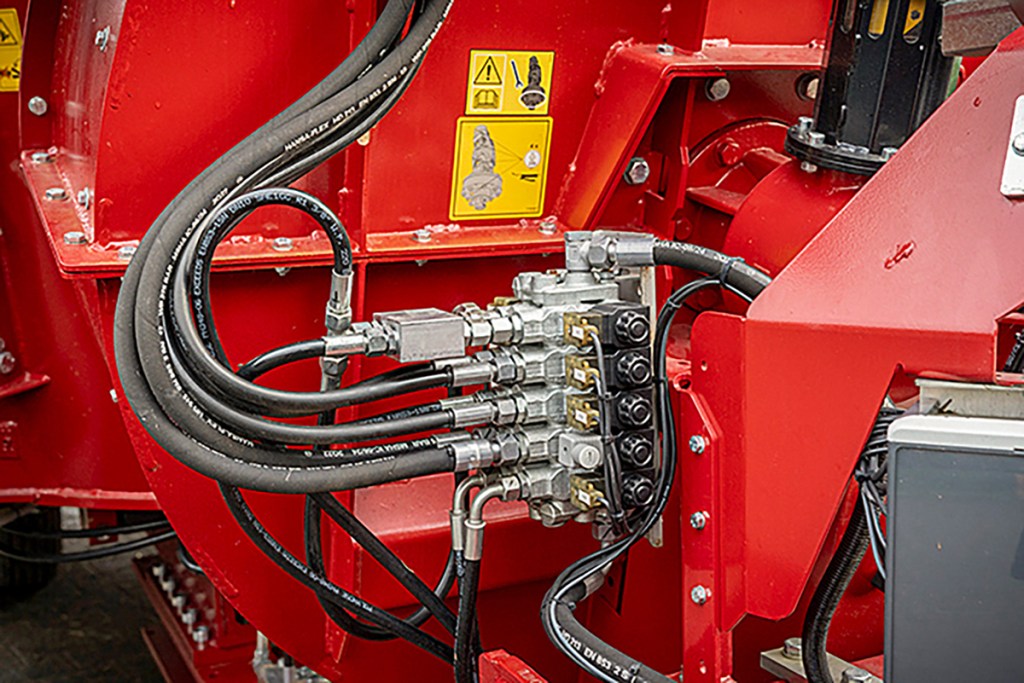

The spout flap, metering door and optional chute swivel are all controlled hydraulically. In theory, you can control these individual functions from the tractor spool valves, but the optional control box is a more practical set-up and only ties up one spool and free-flow return on the tractor — regardless of the number of functions.

Optimised crop flow

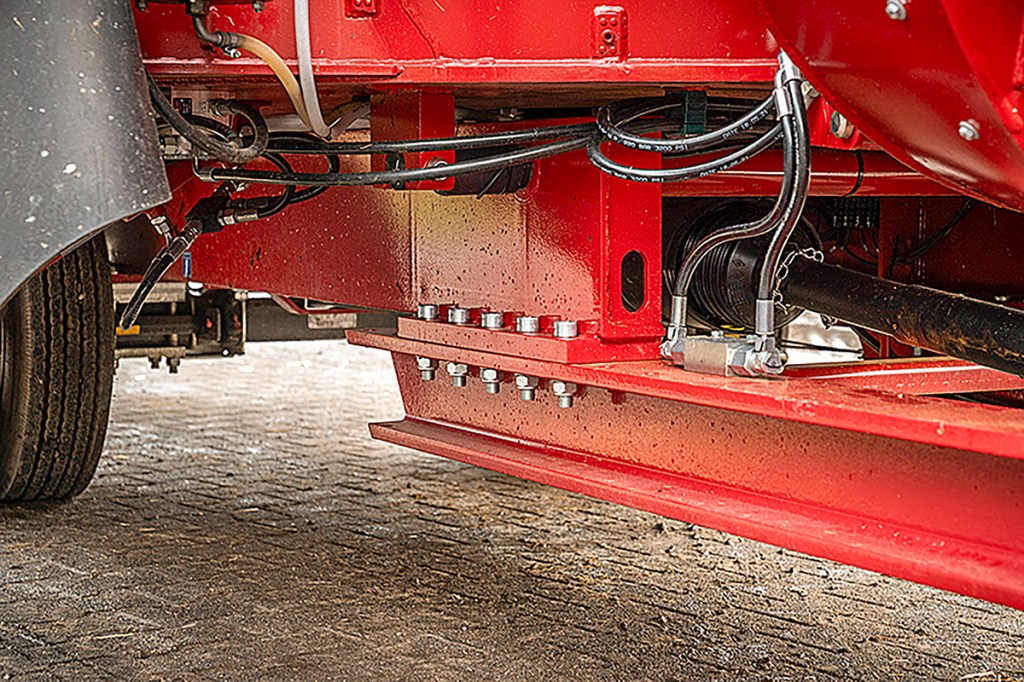

BvL mounts the straw blower at the front of the mixing tub. To accommodate it, the feeder chassis is extended by about 100cm, similar to machines with a cross conveyor. This extra metalwork and the blower add around 900kg to the weight of the feeder.

For optimum crop flow and a straight power flow, the turbine is positioned slightly off centre. The same applies to the sliding door on the tub’s wall, which shuts off the opening to the turbine when feeding.

Material flow is optimised to the blower by what BvL calls a straw bell, a flared piece of metal around the opening. This is also said to prevent stones from becoming dangerous projectiles or creating sparks that could cause a straw fire. The feed channel can also be equipped with a factory-fit stone trap.

One key thing to remember is to shut the door leading to the blower once you have done bedding. If you forget, and start adding your ration mix, the augers will force forage in, so much so, that the turbine will not be able to start up and you will then spend the next few hours digging out the TMR mix. There is currently no alarm system to warn the operator if the door has been left open, so you need to be aware.

There is a water spraying system to control dust. This option uses a nozzle installed on the upper edge of the tub, which is connected to a steel pipe that provides a connection for a water hose. According to BvL experience, 3 to 5 litres per 100kg of straw is generally sufficient to supress excessive amounts of dust in the cattle barn, especially with finely chopped or shredded straw.

The field test

We tried the BvL V-Comfort Turbo bedder on a 20m³ Plus 20 H2S twin auger mixer. It was hitched to a Fendt 312 Vario which the farmer said was a good fit for the machine. We filled the tub with four 2.20m diameter round bales and used the 400m long drive from the straw stack to the first barn for the augers to break up the bales. We didn’t run the water dust suppression system.

Once we arrived at the barn, switching on the straw blower didn’t put too much strain on the 312’s engine thanks to the soft start — very good. With the pto at 540rpm the turbine was spinning at full speed, emitting an imposing and quite loud noise, but it was hardly noticeable in the tractor cab with the windows shut.

The demo machine was equipped with the shorter chute and hydraulically actuated flap. This was perfectly capable of bedding the 20m deep pens from the feed passage. If you need to bed pens on both sides of a passage, then the swivelling chute would be worth considering.

With the door open, the mixing augers start to evenly feed straw to the blower. Going for a low forward speed, up to 300kg/min can be put through the spout without having to stop. Within five minutes, the 200-head in the barn had been bedded down.

Overall, the straw blower is easy to use. We also liked the fact that straw loss on the way to the barn is almost zero — as long as no material has lodged on the hay ring when loading. Another point worth mentioning is that, once the tractor has been warmed up doing the feeding, it can then do the bedding rather than starting another tractor from cold for just a few minutes work.

How much?

The V-Comfort Turbo bedder attachment is a handy option on BvL’s 8 to 40m3 diet feeders. It adds around £16k to the on-farm price with most of the options listed below.

The swivelling chute is just under £1,400 extra. For getting beneath low doorways, budget for £800 for the folding chute. The soft-start assist feature comes in at about £1,800, while the electro-hydraulic costs almost £1,500.

The dust suppression system is just £300, the stone trap less than £400.

Summary

Utilising a diet feeder for also doing bedding is an interesting alternative to a dedicated bedding machine, because you only need one tractor to do both jobs without spending valuable time swapping machines. The sixth generation of the V-Comfort Turbo straw blower proves that the system works well in everyday use.

Owners we spoke to were happy with the reliability and low power requirements of the machine.

One criticism goes to the straw door, which less familiar users may forget to close, while praise goes to minimal losses on the way from the straw stack to the barn, helping to keep the farm clean all year round.

Martin Zäh

For more up-to-date farming news click here and subscribe now to profi and save.