The AF10 is the largest single-rotor combine currently on the market and propels Case IH into the premier league. We caught up with one of the big reds during harvest.

KEEPING IT BRIEF

- According to Case IH, the AF10 has the longest single rotor on the market.

- Performance during our time behind the wheel was impressive.

- The header (£220,000) is not included in the over £900,000 list price.

Having already looked at the twin- rotor New Holland CR, we now had the chance to check out its single-rotor stablemate, the Case IH AF10, which shares several key components.

Drive system changed

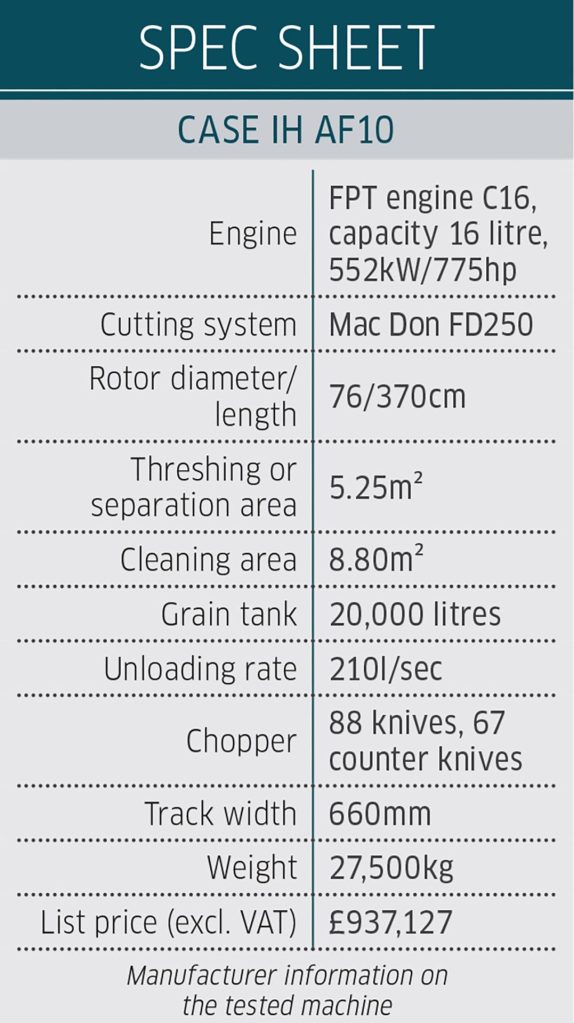

With 775hp, the FPT C16 engine delivers 24% more power than the previous Case IH models. To utilise this power efficiently, the drivetrain has been redesigned. The 16-litre engine is mounted longitudinally; in the direction of travel it’s tilted slightly forward. Directly behind this motor sits a CVT gearbox distributing the engine power to the rotor and the hydraulic pumps.

The rotor can be operated in three different ranges and also drives the feed system. This eliminates the need for a separate drive, the rotor and feed system remaining synched with one another. This layout frees up 10% more space for the threshing and cleaning systems.

Largest single rotor

The centrepiece and typical of Axial-Flow is the single rotor, which has been extended by 103cm (40%) and is 76cm in diameter. It is equipped with 60 threshing blocks; this is the first time Case IH has used the new HX friction blocks, and the rotor cage in the threshing and separation area is also bigger. This loosens up the crop mat and improves grain separation.

Like on the 260 series, the AF10 allows operators to actively control the time the material spends in the concave area by using the electrically adjustable rotor guide rails. Press a button in the cab and the unit reverses automatically, while the sieves, the cleaning system and the augers continue running.

Following the crop flow, there’s a discharge/ejector drum complete with a separation concave arranged behind the rotor that feeds the material to the all-new straw management system. The returns don’t flow back to the threshing unit but are processed by a re-thresher unit from where they are directed to the grain pan. Re-threshing intensity can be adjusted by fitting different covers.

Cleaning performance

The new cleaning system covers an area of 8.8m². Not only is the cleaning area longer but is also more than 10% wider. Stand-out features are the two separate cleaning shoes/screens with their own cross augers. About 60% of the grains are separated in the first-stage of the two-part system. The new fan delivers twice the air output, and the higher cascade steps provide a better separation.

The Side-Shake system automatically levels material on up to 28% slopes. The load on the sieves is monitored by pressure sensors. When the load is uneven, the grain pan and first top sieve jiggle sideways independently of each other, to help distribute the material more uniformly.

Spreading the straw across 15 metres

UK spec AF10s all come with the mounted chopper with 88 knives and 67 counter knives; it’s located at the rear and has two hydraulic independently driven 970mm diameter spreading discs, each with five spreading vanes.

Straw distribution can be monitored by an optional radar sensor, which will then automatically optimise the distribution by altering the disc rpm. This way, Case IH aims to guarantee perfect straw distribution, even at working widths of up to 18 metres. There is a bypass flap for maize that directs the material past the chopper and directly onto the chaff spreader.

New grain tank size

The grain elevator feeds up to 255t/hour and the grain tank holds 20m³. Five sensors, along with the yield monitoring system, provide a continuous 0 to 100% level to the driver. The unloading system delivers up to 210 litres per second — it takes just a minute and a half to empty the tank.

The cross augers in the grain tank can be operated individually so the unloading rate can be halved for topping off trailers and fully emptying the 11m auger. As on the smaller models, the end spout is controllable.

Up front

Big combines need bigger headers, and to solve this part of the jigsaw, Case IH is working with Mac Don to stretch out to 18 metres. To be able to handle these bigger tables, the AF10 has been fitted with a new feeder house. With an optional lift force of up to 6,800kg (110mm lifting cylinder), the combine is able to manhandle these wider and heavier cereal and grain maize headers. According to Case IH, the larger lift rams also provide smoother height control.

The feeder house plate can be controlled hydraulically to tilt/crowd the header by 16° and to either side by 10°. Furthermore, the driver can program in two different cutting heights and then retrieve them with a flick on the joystick.

An optional drive unit can transmit up to 204kW/280hp to the header. Yet another option is a hydraulically controlled flap for the stone trap, allowing it to be emptied by just tapping on the screen. There is even a shake function to ensure it gets rid of all the stones.

Comfortable working place

The view down to the headers and unloading auger is excellent, and, thanks to the large window, you have clear sight into the grain tank. The new leather seat has a massage function, ventilation and heating.

The cab is pleasantly quiet, too. The controls are logically arranged. All functions are operated by switches in the armrest or from either of the two 12-inch screens. Menu pages can be customised and show the images from up to four cameras

Auto-steer is well integrated, and the Vector Pro receiver is attached to the grain tank, protecting it from theft when the tank is folded down — smart thinking. The AccuTurn function allows fully automatic headland turns. Although not applicable to many in the UK, when harvesting maize, the receiver works with sensors on the corn header.

Intelligent threshing

In addition to the hardware, the software has, of course, also been redesigned. The combine provides information on yield and moisture and converts this into yield maps which are provided to customers free of charge. Case IH uses CNH’s patented grain camera to check up on grain quality. This recognises damaged grains and chaff/straw automatically, and the image can be shown on the display. More importantly, however, this info is available to the HarvestCommand automation system.

After the AF10 is pre-configured, the firm’s HarvestCommand will then continuously look to optimise the settings. Using sensor and operator info, the system continuously adjusts all threshing and cleaning settings as well as forward speed. We tried this out in the field, and it noticeably reduced the demands on the operator.

Respectable performance

We tucked the first AF10 into a standing wheat crop in good conditions — it was dry with brittle straw, and the moisture content was around 11%.

Yielding around 6.0t/ha, we were not going to set any records, but the Case IH flagship still showed what it was capable of. Forward speeds of 7.5km/hr with an impressive 15m header enabled work rates of over 11ha/hr and throughputs of around 70t/hr — enough to get the carting crew sweating. In better yielding crops/conditions, it would definitely be capable of more output. Losses were always under 0.5% — we did several tray tests to make sure we were not being duped by the information on the screen.

With 15 metres of straw needing spreading at the rear, Case IH’s new radar-supported MagnaChop straw management system with its automatic control impressed us even with light crosswinds. We also checked the distribution by raking up the residue to see if it was evenly spread, rather than just looking at the stubble.

Gentle on the ground

In our part of the world, the AF10 is only sold on tracks. These are 8% wider, or 66cm, helping to spread the weight but still keeping the overall width pegged to 3.50 metres.

Their hydraulic suspension hasn’t been changed. Four-wheel drive and a semi-auto diff lock will help in a sticky harvest. Thanks to the high pivot point of the rear axle, manoeuvrability is good. A 40km/hr ‘box is an option for the AF10.

Service and maintenance

The radiator pack is mounted between the engine and the grain tank, as this is where the cleanest air can be drawn in. Thanks to the longitudinally mounted engine, the air flows nicely around the block helping keep it free of debris, says the company. The air filter is easily accessible from ground level.

There are no daily grease points that need attention; belts are quickly checked for the correct tension with gauges. Indeed, many of the components are maintenance-free, except for the chopper which needs a shot of grease every 50 hours. All of the other service points are on 100 hours +.

Summary

Case IH hasn’t just added more power to what it already had; this is a new machine that supersizes the single rotor that it is known for. And that also means the rest of the combine has had to be redesigned to match the harvesting ability of the AF10, which moves Case IH up the combine league. The list price of £937,127 (plus £220,000 for a 15m header) is also new territory for the big red, but our brief experience shows that it can cover some serious ground with minimal losses, while, at the rear, trash is evenly spread.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.