Caterpillar has freshened up its biggest agri-orientated loading shovel, the 938 Ag, which offers a high level of comfort and a number of nice details.

KEEPING IT BRIEF

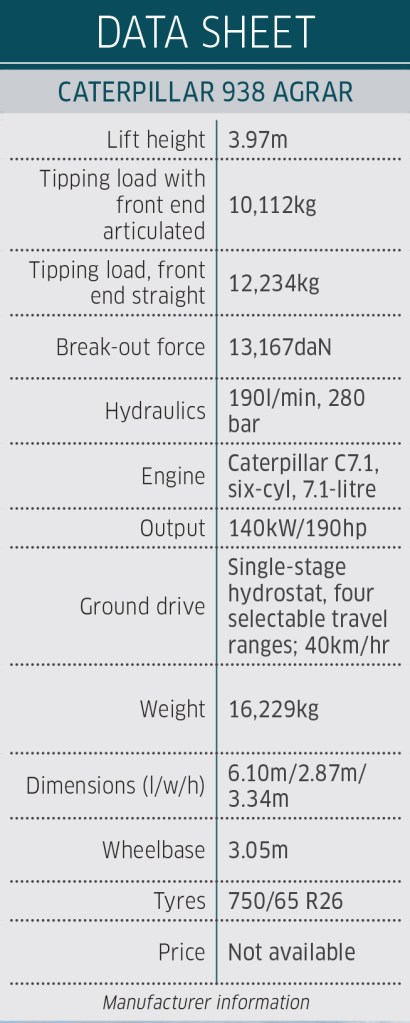

- With a tipping load of 10.1t, the 938 Agrar is the top model in Caterpillar’s agricultural range.

- The cab has seen the biggest change.

- Automatic traction control is reckoned to boost performance and reduce wear.

Last year Caterpillar updated its ‘small’ wheeled loaders, a trio of models, the 926, 930 and 938. We managed to catch up with the 16t, 190hp model, the 938, to take a closer look at the changes. Our featured machine also gets the extra Agrar tag in the name, as German Caterpillar distributor Zeppelin has created this ag spec machine so that it can standardise on certain options.

No steering wheel

First thing you notice in the updated cab is that the latest 938 is steered from a joystick on the left-hand armrest of the heated and ventilated premium driver’s seat. Once you have had a bit of mental readjustment to this way of steering, it’s great. Pluses are better forward visibility, more space in the cab and a more relaxed driving position.

What’s different to other manufacturers’ stick steering systems is the firm’s patented steering circuit, which means it doesn’t need a steering wheel even on public highways, provided it’s homologated for 40km/hr. As the travel speed increases, the sensitivity of the Cat’s steering joystick automatically decreases for more precise control and safe steering.

To improve visibility on the right-hand side there are two smaller screens on the A-post rather than one big display. The right-side window is also deeper, and the B-post has moved farther to the rear. Then there are the additional cameras on the rear-view mirrors and at the rear, plus the fold-down front camera on the roof provides a 360° bird’s eye view of the surroundings on the 8” screen.

The adjustable armrests are now mounted on the seat and have been redesigned for better comfort. The main joystick on the right even has assignable buttons for more control options.

Lifts and weighs — (almost) always

Leaving the cab and focusing on the loader hardware, the 938 Agrar is manufactured in Brazil and makes a well dimensioned, well-crafted impression. Cat’s own figures suggest the sizeable boom with Z-kinematics has a max load height of 3.96m at the pivot pin and also develops a break-out force of 13,167daN. An optional high-reach boom adds another 60cm to the lift height. Return to dig positioning at the touch of a button is a standard fit.

On the options list is a new weighing system that is integrated into the Cat Productivity telemetry package. This set-up weighs the load dynamically on the move. The non-calibrated weighing system is installed on all machines and can be used for the first 250 hours free of charge. If you take a liking to it, then there is a one-off payment of €3,700 for the activation. You can create various attachment profiles with regard to crowd/dump angles, parallel lift control and boom cushioning.

Smart solution cuts out wheel slip

Compared to the smaller loader models, the 938 Agrar benefits from a larger, intelligent drive motor and bigger axles. Caterpillar’s Rim Pull wheel slip control system is able to reduce the torque at the wheels.

The operator can either enter the maximum torque manually on the terminal to prevent spinning on slippery surfaces or use the automatic function. The 938 then detects current wheel slip with the help of pressure and speed sensors in the drivetrain and auto adjusts the power to the wheels and, if needed, engages the fully locking diff.

On a silage clamp with a 5.0m folding fork, the 938 Agrar worked without any fuss; the wheels barely spun when hitting the heap. The operator can keep the pedal pressed and utilise the boom’s full power.

Under the bonnet

Lastly, a look under the bonnet. Small LED lights illuminate the most important service points and come on the moment that the bonnet opens. The 938 Agrar is powered by a 7.1-litre Caterpillar six-cylinder lump with 140kW/190hp and a 1,000-hour service interval.

The automatic engine management system is new: the 938’s operator can adjust the aggressiveness in three stages and cut the idling speed to 800rpm. It also shuts off the engine automatically after 3 to 60 minutes of idling (programmable). The demand-controlled reversible fan is a standard feature as part of the agricultural package.

Caterpillar uses a single-stage hydrostat transmission. The user can adjust the maximum speed and therefore the pedal speed range in four stages. The operator can also choose between various driving modes from the 8-inch touch screen, such as torque converter or pedal mode.

Other details

- The loader’s headlights are switched on automatically by a brightness sensor.

- List price for the 938 kitted out for farm life has yet to be announced.

Lucas Colsman

For more up-to-date farming news click here and subscribe now to profi and save.