Cereals takes place in Lincolnshire this year, at Roy Ward Farms near Sleaford. There’s the usual mix of crop plots, seminars and arable machinery, with some working demonstrations thrown in for variety. Tickets and more details at cerealsevent.co.uk

TRACTORS

John Deere 9RX

The world’s largest production tractor will be a key draw to John Deere’s stand. Visitors will get chance to take a look at the 913hp 9RX 830, flagship of the company’s new articulated range.

The E21 powershift box features 21 gears that can be shifted manually or automatically, and the power is transferred to the tracks to drive the machine which can have a maximum ballasted weight of 38.1 tonnes. Deere says ground pressure is as low as 0.58kg per cm² – comparable to the three smaller models in the line-up.

The G5 Plus screen is standard, with the option of double the viewing area with an extended monitor. A new corner post display has also been fitted.

The isolated subframe suspension has been borrowed from the 8RX which significantly reduces the noise and high-frequency vibrations typically associated with road transport.

CULTIVATIONS

Kverneland hoes and ploughs

Kverneland is returning to Cereals after several years’ absence. The company will present a range of mechanical weeding solutions including the Helios – a star-wheel equipped rotary hoe suited to cereal crops, and the Onyx tined hoe, designed for inter-row applications such as maize, sugar beet and veg crops.

At 6.0m wide, the hydraulically folding Helios rotary hoe uses a series of cast iron star wheels, mounted in pairs on a tandem axle. Downward pressure for each pair is controlled by adjusting the amount of hydraulic pressure applied to the star wheels to carry out shallow weeding through the top 10mm of soil.

For inter-row applications, the Onyx can be combined with a Lynx guidance interface plus camera and control panel technology from by Tillett and Hague, for enhanced precision. The guidance interface sits between the weeder frame and tractor three-point linkage and can be equipped with up to two forward-facing colour scanning cameras to provide active side-shift of up to 25cm.

Kverneland’s Ecomat shallow plough range has been extended to include models for in-furrow use, in addition to on-land versions. In-furrow models are available in six-, seven- and eight-furrow builds, and join the existing eight- and 10-furrow on-land versions. Developed as an option for minimum disturbance seedbed preparation, the Ecomat shallow plough offers mechanical control of pests and weeds through soil inversion, reducing the reliance on chemical methods.

Maschio Jumbo power harrow

Maschio Gaspardo introduces the Jumbo X power harrow which offers an adjustable working width of 9-10m with three floating sections to adapt to ground contours. It is designed for tractors from 450hp and lateral transmission is by means of special triple-jointed shafts with cooling on the four gearboxes

The Jumbo X is equipped with ISObus control, allowing for easy adjustment of roller height, working depth, levelling bar position, and machine telescoping functions. The system also monitors temperature and rotation speed (rpm) across gearboxes, ensuring optimal performance.

The sliding side sections allow the unit to fold to 3.1m wide and 4.0m high for transport; a patented pair of twin wheels located under the central frame alleviate some of the load when being transported.

Grange GLL Lite

Grange Machinery will launch the 2.5m working width Grassland Loosener Lite (GLL Lite). It is based on Grange’s popular 3m Grassland Loosener but built on a more compact scale to accommodate tighter spaces and smaller tractors.

The GLL Lite is aimed at livestock farmers and those running mixed farms, but is also likely to prove popular with growers who direct drill wanting to lift and loosen the soil structure without creating another pass before drilling, suggests Grange.

The three or four front cutting discs enhance the loosening element of the leg and eliminate surface tension. This reduces the potential for soil boiling in front of the leg and eases the flow of trash through the machine. Options include either shear bolt or hydraulic reset protection, an LED road lighting kit and a 2.5m toothed packer roller.

Amazone knife roller cultivators

The 12.1m working width TopCut 12000-2T knife roller cultivator makes its debut, designed to mulch green cover. It consists of up to three consecutive tool segments, plus a rear segment that can be equipped with various tools. A combination of knife rollers and/or minimum till discs, with optional front leading knife roller, creates a machine that can be customised to a farm’s exact preference.

The TopCut is also suited to shallow cultivation of 0-2cm. The knife rollers produce enough fine soil to produce a seedbed, encouraging weed seeds and volunteer cereals to germinate. Working speeds are up to 20km/hr and reversible knives on the knife roller reduce wearing part costs.

Amazone also promises small and large plough introductions.

DRILLING

More Horsch Partners

Available as small pre-series in 2024, the Horsch Partner front tank range will now include a number of new models.

The Partner FT hoppers can be combined with a range of mounted drills and implements to create flexible and versatile seeding systems, says Horsch. A double-tank 1,600-litre option now joins the existing single tank of that size and there are new double-tank models with 1,700- and 2,100-litre capacities plus a 2,500-litre triple-tank model with 2,500-litres.

The Partner FT is now equipped with the new I-Manager operating system, proven on the Pronto, Versa and Avatar drill lines.

New packer options distribute the weight on the front of the tractor to reduce tracks and minimise soil compaction.

The Horsch Partner support kit for pneumatic piping, available for the existing front hoppers and is compatible with the new models consists of an adjustable attachment arm that can be positioned for height and attachment angle depending on the tractor.

Pöttinger presents MaterMacc

One of the highlights on Pöttinger stand will be the first showing of the MS9100 precision planter in the UK. MaterMacc is an Italian company that specialises in the design and production of precision pneumatic seeders. Since November 2022, MaterMacc has been part of the Pöttinger Landtechnik group.

The MS9100 precision planter has a front folding frame with sequentially operated wheel supports and telescopic drawbar. All the movements are hydraulic and managed by electro valves with sensors for an easy folding-unfolding sequence. The 180mm square section foldable frame) is suitable for 70 and 75cm row spacing with a working width of 6.0m and transport width of 3.0m.

The planting unit can be used conventional, conservation or direct drilling systems, with up to 250kg in down force available when needed.

The Magicsem Plus metering unit is made of a special blend of polymers and fibreglass for strength. Agitation inside the loading chamber improves seed drawdown even at high speeds while protecting seed integrity, says Pöttinger

Switching from one crop to another is achieved by changing the seeding disc and varying the height of the selector.

Alpego DTEK combi drill from Opico

OPICO is to relaunch Alpego’s 6.0m DTEK power harrow combination drill paired with an ASPro front hopper, having taken the brand on at the end of 2024.

The Dtek Rapido folding power harrow features Alpego’s Twin Force Tek – matched pairs of rotors fitted with calibrated Timken taper roller bearings. Rapido quick-fit drop forged tines are fitted as standard with two tungsten carbide options available and there’s a choice of three rollers

The seeding bar is mounted on the rear of the power harrow via a parallelogram linkage, with 12.5cm spacing standard with 15cm rows an option. Staggered at 43cm, each opener can generate up to 60kg of downforce.

Positioned above the seeding bar, the distribution head incorporates a patented Turbo Rotal impeller system for uniform distribution to each outlet even at very low application rates.

With a 1900-litre capacity, the ASPro front hopper features a stainless steel Dosal electronic metering unit capable of dealing with application rates as low as 2kg/ha and as high as 450kg/ha. The ASPro front hopper press wheel option can aid in pre-drilling soil consolidation

Rate changes are via the RDS Super control box; Pre-start function and electronic half-width shut off is standard with ISObus an optional upgrade.

Claydon NutriSeeder

Claydon introduces the NutriSeeder, designed for cover crop establishment. Two versions are available for the Claydon straw harrow, a single 200-litre hopper with a single metering mechanism, or a twin-hopper design with dual metering systems. The latter allows two types of seed to be applied at the same time and mixed in the distribution head, providing higher capacity and more accurate metering whilst avoiding seed separation in the hopper.

Both NutriSeeder models incorporate a hydraulic fan and electronic control with forward speed rate mechanism. On headlands, the NutriSeeder is started and stopped by the operator, as best practice is to leave the straw harrow down so as not to release weed seeds or drop clumps of straw.

Fitting different metering wheels/sections enables seed rates to be adjusted up to 30kg/ha for wheat, 15kg/ha for grass seed and 25kg/ha for cover crop mixes, at a forward speed of 15km/hr. Eight spreader plates at the front of the straw harrow distribute seed evenly in front of the implement’s standard 14mm or optional 16mm-diameter tines which create a shallow tilth up to 30mm deep, ensuring good seed to soil contact.

Aerworx Viper drill

The Aerworx Viper Series direct double disc drill is designed to be simple, efficient and cost effective. For both grassland and arable use, the Viper can accommodate a variety of seed sizes: wheat, barley, grass, clover, peas, sunflowers etc. It features 19/21/23 rows of 10mm spring coulters with tine spacing of 125mm with working widths up to 3.0m. Standard hopper capacity is 1,000-litres (other sizes available) and can be specified for seed and fertiliser or seed only. It is said to offer easy and accurate seed calibration and manual or hydraulic depth control up to 100m.

The Viper is designed to work alongside the company’s Aerworx drum aerator which can alleviate compaction before drilling.

SPRAYERS

John Deere tech on R962i sprayer

John Deere will showcase its See & Spray spot spraying technology as well as the new Individual Nozzle Control (INC) Pro upgrade on the flagship R962i trailed sprayer.

INC Pro technology improves application accuracy and reduces chemical usage, saving the operator money. It is designed to take the stress out of maintaining a constant speed during conventional applications by using pulse width modulation technology to deliver a consistent application rate at constant pressure, producing the same size droplets, whatever the speed of the sprayer.

BFS ABTJ

BFS Farm Services introduces the BFS ABTJ – Air Bubble Twin Jet Nozzle, designed to deliver superior pesticide coverage through a twin-angled spray pattern (30deg forward and 30deg backward).

The ABTJ enables precise application of spray volumes on dense canopies using a smaller twin fan orifice, creating finer droplets without increasing drift risk. The opposing spray angles ensure uniform crop coverage, including stems, leaves, and hard-to-reach areas.

Designed to be ideal for pre-emergence applications at 200l/ha, it offers clod coverage and is equally effective for fungicide and herbicide use at 100l/ha. The nozzle is available in 025, 03, 04, and 05 ISO sizes, making it a versatile solution for various crop protection needs.

GRAIN

Alvan Blanch dryer and cleaner updates

Alvan Blanch will show the latest adaptations to its proven grain drying and handling systems, designed to help farmers navigate current farming conditions.

The Alvan Blanch continuous double flow grain dryer is now available with a mobility package to suit the farm’s needs and to avoid the need for planning and infrastructure at the farmyard. It is designed to be future-proof to be relocated to suit changing farming operations. Features included a fold down roof and detachable hopper for easy set up; it is available in a basic ‘on farm’ specification for moving around the farm or with a full road kit for towing at up to 30kph. Crops can be dried without pre-cleaning, and inbuilt air recirculation allows heat from the dryer to be re-used, saving on fuel. Models are from 6.0 to 28t/hr input capacity.

The Rotary Cleaner/Grader has been adapted for intercrops, using an aspirator and four screens to allow cleaning and grading of one crop, for example oats, with the other two screens used afterwards to process beans. The system can be mounted on a trailer or stand. The system suitable for 20-100t/hr throughputs.

The company has also been capacity testing for cleaning of novel crops such as buckwheat and borage seed.

Load cells and weigh systems from Griffith Elder

Griffith Elder will exhibit its Mass-Tel Range of ISObus load cells and weighing systems, which feature plug-and-weigh technology for a seamless, high-performance user experience.

Entirely designed in-house, the Mass-Tel range offers reliable solutions for agricultural, automotive, and off-road machinery applications. At the system’s core are load cells with embedded CANbus ECUs, which connect directly to ISObus or J1939 protocols, eliminating the need for junction boxes or interface electronics. Operation, setup, and diagnostics are handled via a standard ISObus Universal Terminal, with the load cells providing the user interface directly to the screen. Third-party integration is efficient and straightforward using ISObus or Griffith Elder’s proprietary protocol. The system also supports Mass-Tel Utilities (MTU), which offer expanded connectivity such as Bluetooth and remote displays.

The Mass-Tel App connects via bluetooth, mirroring the Universal Terminal interface while adding enhanced functionality. Its modular connection system lets users link multiple hardware options simultaneously, creating a flexible and future-ready weighing solution.

DEMONSTRATIONS

Demonstration areas are a popular feature of the event, with live action in the Sprays and Sprayers arena and a drill demonstration allowing visitors to compare machines from Taege, Dale Drills and Novag. A number of exhibitors will have demonstration plots adjacent to their stands, so look out for action from Agriweld, AgXeed, Vredo and TWB. There’s also change to get behind the wheel at the Isuzu Offroad Driving Experience.

Merlo on show

Merlo UK is one of the returners to the event and also offers live action on its adjacent demo plot. Alongside the TurboFarmer TF42.7CS, with 4.2-tonne lift capacity and 7-metre reach and the 5 tonne capacity, 7.8m lift height TF50.8T HF which features boom suspension on static display, the TF38.10 TT will be in action at the demonstration plot. With a 9.7-metre lift height and 3.8-tonne capacity, this machine is said to be ideal for stacking bales or fertiliser bags at height. Its three-stage boom, and TT system (hydraulic frame levelling and boom side-shift), allows for precise load placement. Adaptive Stability Control System (ASCS) is also standard on this machine, which includes a live digital load chart, automatic attachment recognition, and a large in-cab 10.1in colour display, integrated weighing system and operator profile settings.

APPLICATORS

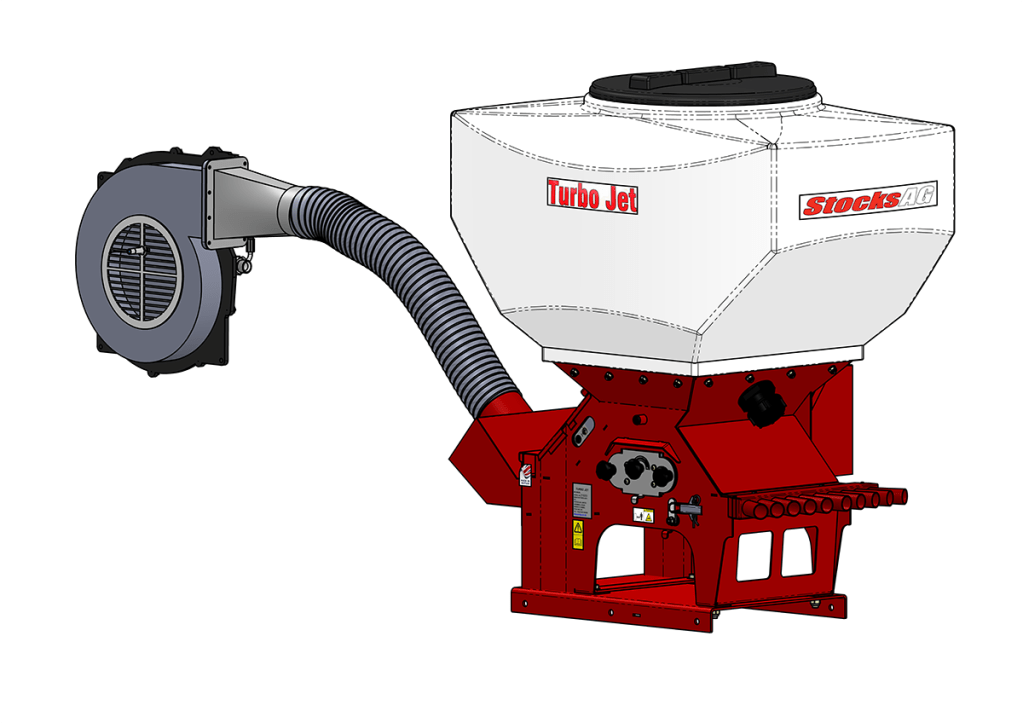

Stocks Turbo Jet 10 HD

Making its debut, the Stocks Turbo Jet 10 Hydraulic (HD) provides users with maximum airflow for higher application rates at working widths from 10m up to 15m. It can also be run at faster forward speeds and be set up to apply full-width, in bands or in rows as required.

Demand for wide working widths has led Stocks to develop an applicator with more air flow to apply small to medium sized seeds such as oilseed rape, clover, grass, mustard, etc. at high rates from 10m as well as micro and granular products at low to medium rates, all at up to 15m. Product is metered by a rotary feed and delivered pneumatically, using a multi-blade, 1400cfm, 4in hydraulic Crary fan.

Testing has been carried out on a range of products including slug pellets, wheat, barley, OSR and Avadex. Working at 15m and applying a precise, low-rate of Avadex granules, it produced a Coefficient of Variation of +/- 5%.

The applicator is supplied with either 10 or 20 outlets and with either a 240 or 400 litre hopper. Jackal or the I-CON control units can be specified, both offering fan speed and function monitoring. ISObus-ready machines are also available.

For more up-to-date farming news click here and subscribe now to profi and save.