Arriving in 2017, the Axion 870 was a late addition to the Claas tractor range, but its 197kW/270hp of rated power means it still falls into the universal workhorse bracket — big enough to pull acre-eating kit but doesn’t look out of place when hauling trailers. We find out what it’s like to live with for 5,000 hours.

KEEPING IT BRIEF

- The Claas Axion 870 has undertaken a variety of tasks on an arable and contract farm … and clocked more than 4,900 hours in the process.

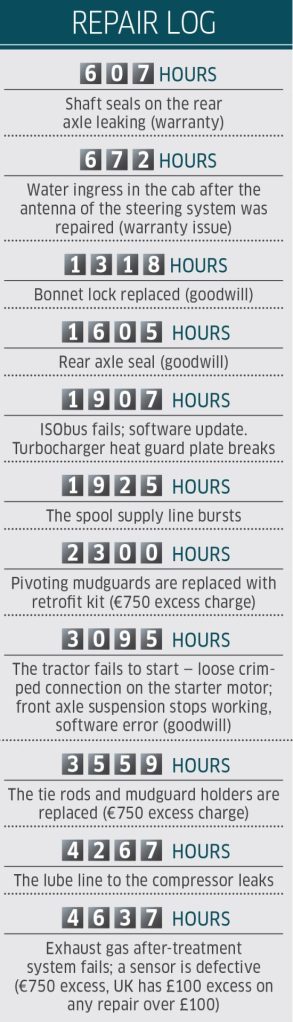

- The tractor’s repair log lists various small-ish items.

- Performance and aptitude for field work are convincing.

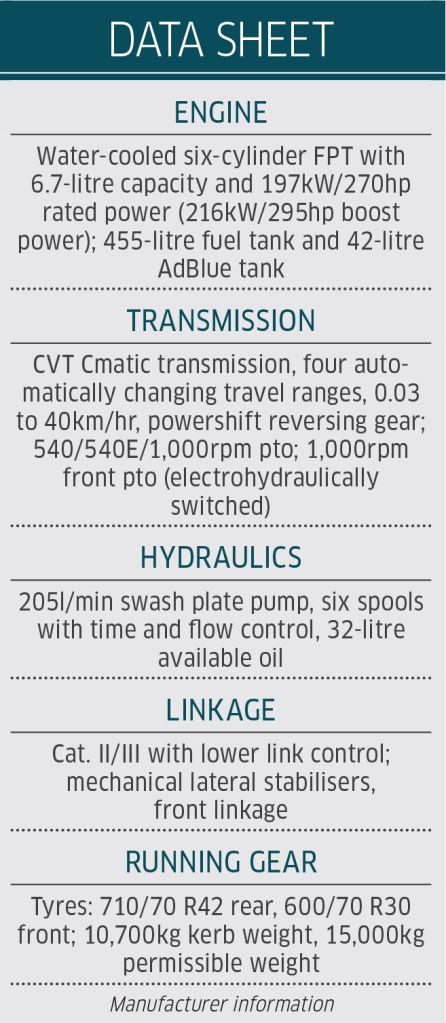

With a rated engine output of 197kW/270hp, the 870, is the biggest model in the 10,700kg, Claas Axion 800 range before crossing over to the heavier 900s. With its boosted output of 216kW/295hp, it falls into the same power and weight category as a Deere 6R250, Case IH Puma 260 CVX, Valtra Q, New Holland T7.300 and even Fendt’s new 800s. That’s some stiff competition in what is becoming a very hotly contested power bracket. Our farm/contractor owner gives us the low-down.

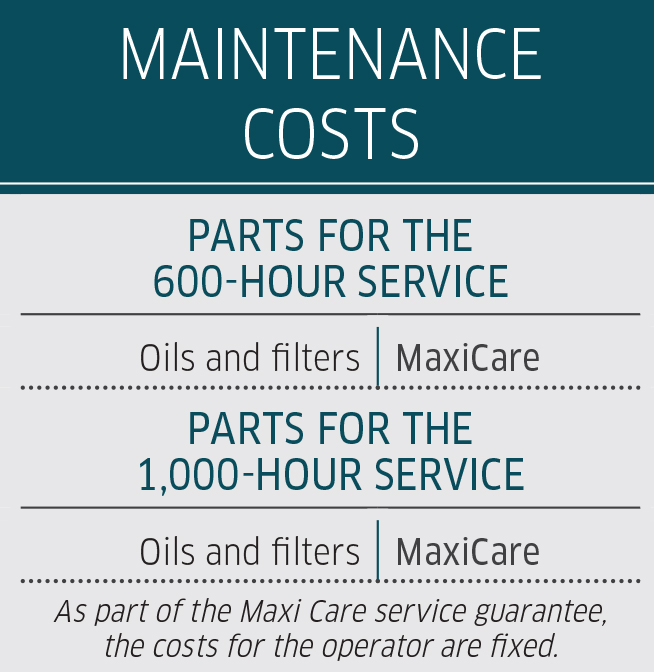

This is the prime mover in the fleet, running alongside another 870 and a smaller Axion 810 plus several Fendts in Wesermarsch, northern Germany. The 420-hectare farm also operates a biogas plant, so, due to the workload, the owner opted for the Maxi-Care maintenance and service plan, hiring the Axion from his local dealer for 7,500 hours at a fixed hourly rate. This will help to manage risk and fix costs over the 7,500 hours/five years the test tractor is expected to stay here.

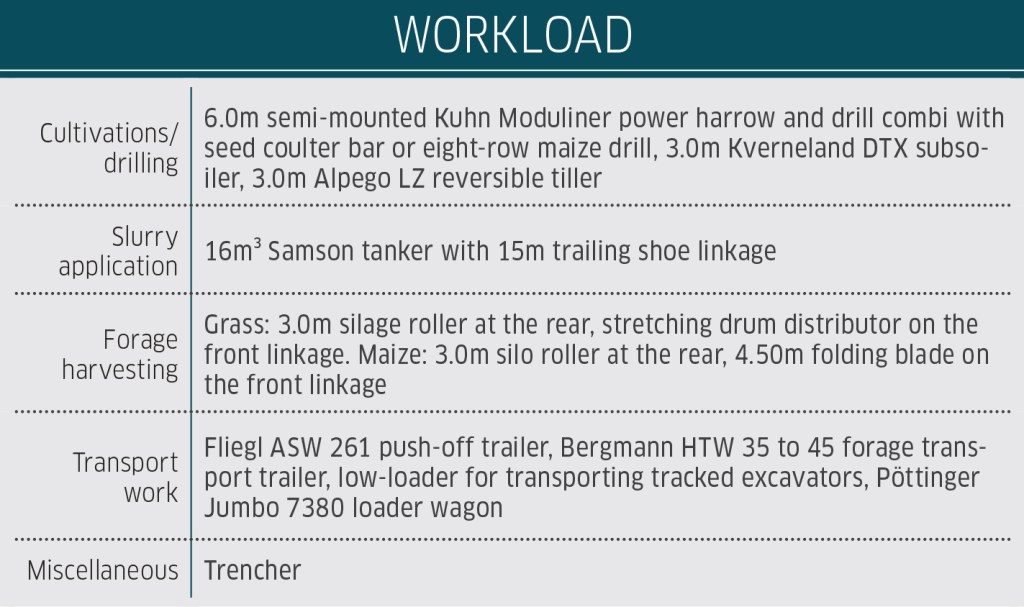

When they arrived back in 2022, the two Axion 870s had some big boots to fill as they replaced an Axion 930. They inherited 930-size implements, with their work sheet including using kit such as the Kuhn 6.0m power harrow drill combination and a 3.0m wide subsoiler that is set to loosen the marshy soil down to 40cm deep.

Economical, but small fuel tank

After clocking more than 4,900 hours, the owner’s first niggles relate to fuel: the 455- litre fuel tank is too small; and the driver shouldn’t rely on the fuel gauge as it doesn’t always truly reflect the actual diesel level in the two tanks — one left, one right. A much safer bet is to glance at the screen, which will tell you how much work you can still do before you’re in trouble.

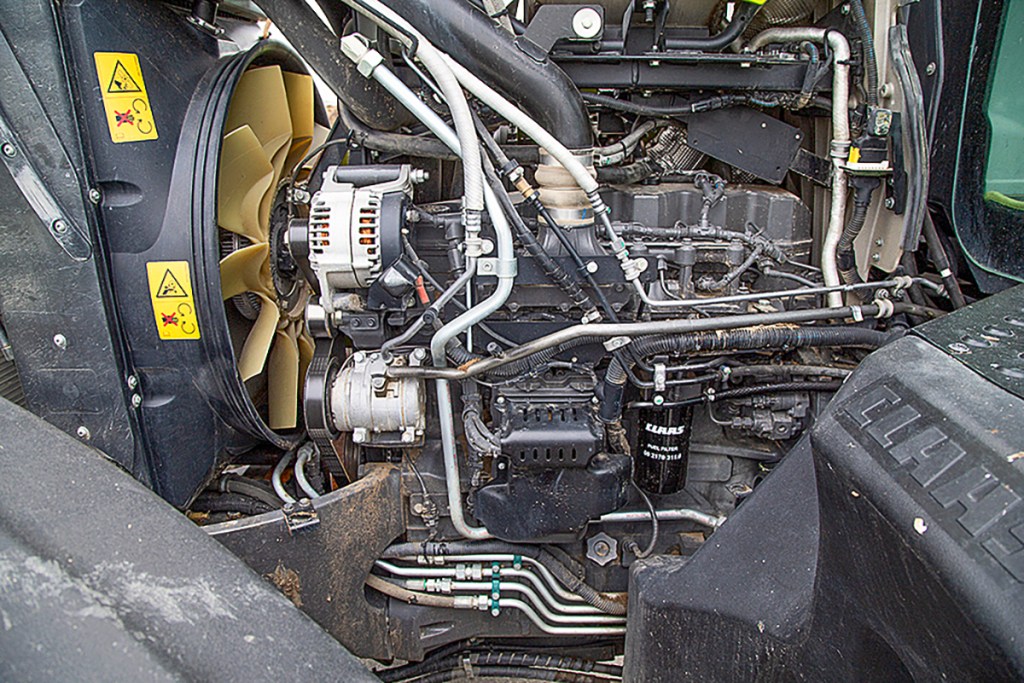

There is no issue with the fuel consumption from the owner. Moreover, the owner is not just happy with the Axion’s fuel economy, but also the overall performance of the six-cylinder, 6.7-litre FPT motor.

Engine-related niggles

There have been no really serious engine problems, but there have been some minor related issues — for instance, a broken hood latch and the broken heat shield at the turbo, while the V-belt had to be replaced after 4,600 hours.

There was an issue with the sensors on the exhaust after-treatment system at 4,637 hours. There have been one or two other issues throughout the year, but keying off and back on again has so far solved these issues. Our owner does stress it’s important to use clean AdBlue to avoid problems.

Moving on, the radiator pack performs well, even in dusty conditions, such as powering the front-mounted silage spreader when levelling and rolling the clamp. When the radiators do need cleaning, they open out from the bottom with a firm pull.

Frustrating, however, is that the gas stuts that are supposed to hold the radiators in their open position aren’t strong enough for the task.

Great gearbox, weak seal

The Axion’s users really like the very good engine-transmission set-up, making a point of how easy the ‘box is to use with the three driving ranges being very practical.

Operators particularly mention how they can accelerate or decelerate the tractor from the current cruise control speed using the Axion drive lever. ZF’s Terramatic TM28 transmission responds smoothly under any sort of load. However, the noise from the hydro unit is noticeable.

As well as field work, the 870 has spent a good chunk of its life on silage clamps. We cannot say exactly if it was the dual wheel on the right-hand side, or the weight of the 3.5t compactor, that caused the wear on the axle seals. One seal was replaced at 607 hours, but then at 1,605 hours all of the seals were done.

A much bigger blot on the Axion’s reliability record occurred at 1,925 hours when the main supply pipe to the rear spools burst. The high capacity 205l/min piston pump quickly dumped 70 litres of oil across the silage clamp, which was clearly far from ideal.

Reliable couplers

The five spools at the rear of the tractor receive good marks — firstly because they are clearly labelled with long-lasting colour markers, and secondly because you can always plug in the coupler thanks to the pressure relief valve.

Overall, the Axion operators were happy not only with the hydraulics but also the linkage, the lower link stabilisers and the lift capacity.

And speaking of lift capacity, for a 300hp tractor the weight distribution between the front and rear axles is good. Of the tractor’s 10.7t working weight, 58% rests on the rear axle and 42% on the front. User experience is the Axion doesn’t need a front weight to safely tow a trailed machine with a higher hitch weight, despite the K80 ball being pushed 12cm rearward on the drawbar.

However, with a permissible gross weight of 15t, you should be aware of the total weight to avoid overloading. As for braking, the tractor always comes to a safe stop. The brakes even respond too strongly for some drivers who would prefer a more progressive response. The park lock also activates the air trailer brakes and earns top marks.

Tie rods and mudguards

Our featured tractor has a Trimble auto steer set-up. This retrofitted system was the reason for rain leaking into the cab at 672 hours, a missing seal in the cab roof being the pinpointed culprit. The steering system is operated from an extra screen in the cab — the owner likes this solution, as it means the Cebis display on the armrest can be used for ISObus machines or remain free. But once you add the additional tablet (used for running software for contracting jobs) and CB radio, there is not much spare room on the right-hand side of the cab.

At the same time as the tractor was being serviced at 3,559 hours, both the track rods and the bearings in the swivelling front mudguards were replaced. It seems that the jerky steering movements from the auto- steer system are the main reason for the increased wear on these points.

Furthermore, the elongated holes in the front mudguard brackets were criticised because the mudguards gradually keep slipping out of position.

There are no issues with the sturdy Carraro front axle apart from one instance where a faulty valve allowed too much oil into the cylinder on the suspension system. And at 3,095 hours, there had been a software issue with the suspension system. Generally speaking, the Axion’s suspension comfort is rated as about average compared with the other tractors on the farm.

For ‘no-screen’ drivers

The tractor is used by several operators, who have all been able to quickly figure out the 870’s cab. The fact the hitch, pto and climate controls settings don’t have to be adjusted through the screen is a good thing as far as these operators are concerned. Having actual physical controls is a plus for less tech-savvy users.

But for those who do like a bit of tech and customisation, the armrest offers a great deal of adjustment potential. Assignable F-keys on the Axion’s Cmotion joystick and the comprehensive headland management system are worthy of a mention. The main joystick controller is rated as being very ergonomic and shows little sign of wear after nearly 5,000 hours. The powershuttle on the steering column is the preferred method of making direction changes; the buttons on the joystick that do the same job are hardly ever used.

At around 1,900 hours, the software had a wobble, and the tractor would no longer detect any ISObus-connected machines. The dealer re-installed the software and since then the tractor has been back on speaking terms with the other ISObus kit.

Four posts

The cab may be a bit long in the tooth but still gets good marks for generous legroom, even for taller drivers. Other good points include convenient access, the lighting and the perfectly integrated, dust-proof tool drawer. The biggest grumble concerns the heavy, poorly closing door.

There is decent visibility down the sides of the bonnet to see the front linkage when hitching up and when working on the clamp. But the view out the rear window, to the rear linkage, is not so good.

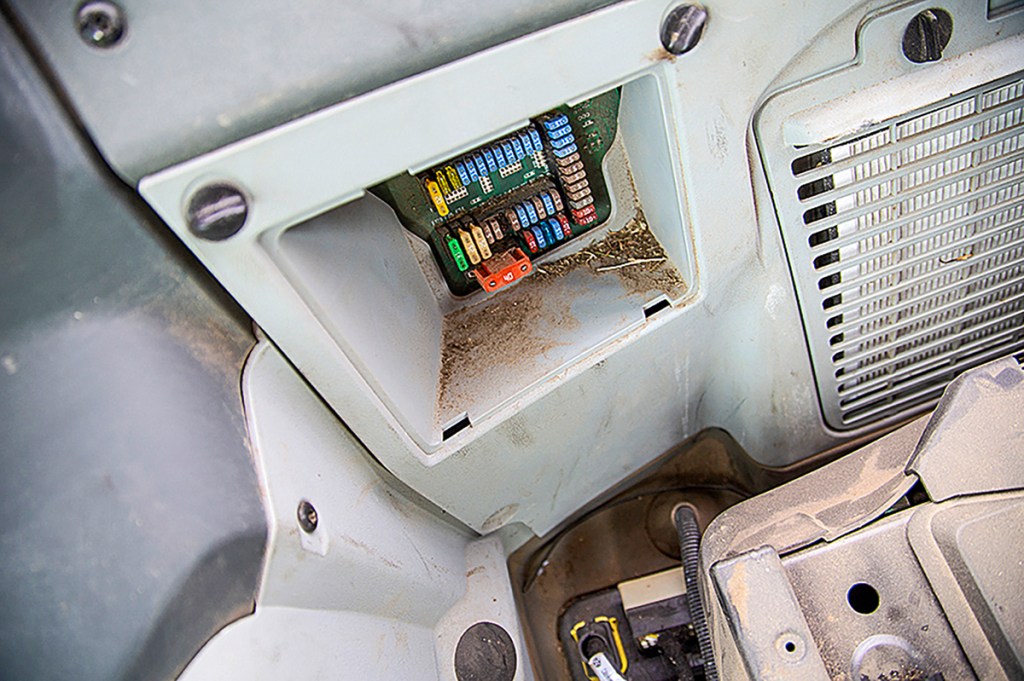

Service and design

When the Axion refused to start after 3,095 hours, the team initially searched for a blown fuse in the three fuse boards dotted around the inside of the cab. But the culprit was a loose crimp connector on the starter. It was just a matter of re-crimping and the 870 was good to go.

The Axion’s engine oil is changed every 600 hours and then a major service including a transmission oil change is at every 1,200 hours. Because the business opted for the dealer’s Maxi-Care service as part of the 7,500-hour hire agreement, there are no additional maintenance costs apart from the fixed hourly rate. In Germany, Claas offers a warranty with a deductible €750 excess on any repairs that exceed €750. Here in the UK, it is a £100 excess on any repairs exceeding £100.

Summary

Our long-term test Axion 870 has had to prove itself tackling a range of arable and contracting jobs and has managed to clock up more than 4,900 hours since arriving in 2022. Performance, fuel consumption and ease of use have impressed the multi-pronged business, which opted to contract hire the tractor to help fix costs.

Apart from the front mudguards working their way loose, there’ve been no recurring problems in the near four years it has been in the fleet. However, breakdowns such as the burst hydraulic pipe and leaking shaft seals on the axle have blotted its otherwise decent health record.

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.