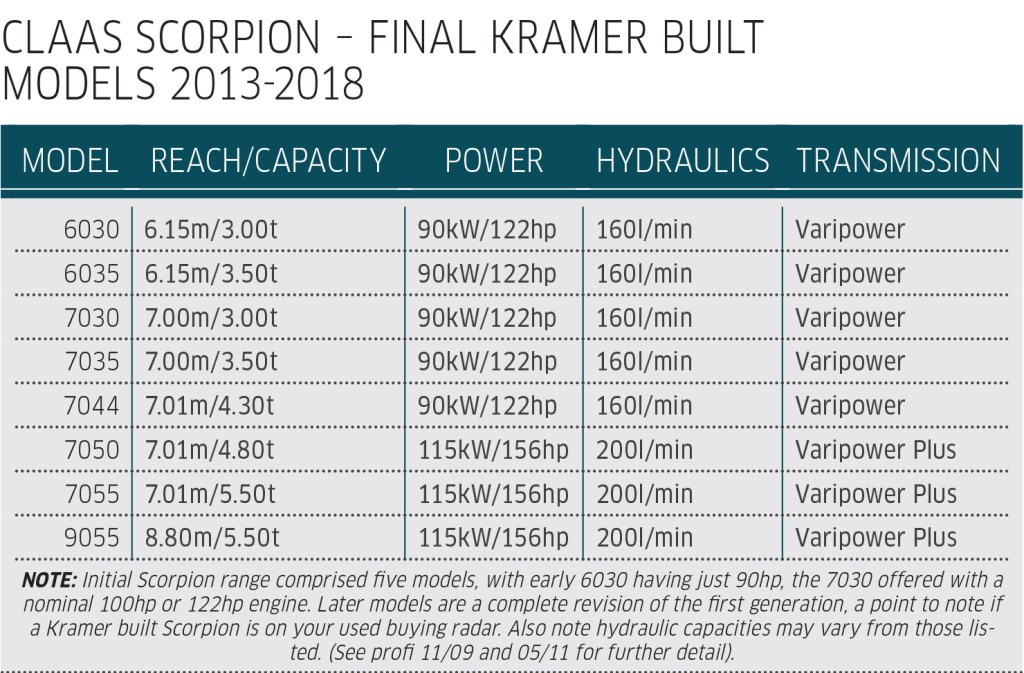

Although Claas announced it was ending its telehandler partnership with Kramer back in 2015, it was not until 2018 that the current Liebherr built models arrived in the UK. A lack of supply held back initial sales, but as availability ramped up so too has the popularity of the handlers with a growing, but still relatively small park of used models.

Claas wasn’t daft enough to go back to a clean sheet of paper with the Liebherr built Scorpions, indeed these make use of several components from the previous Kramer models they replaced. For instance, there is the same 3.6-litre and 4.1-litre Deutz engine family as before and Varipower transmissions. The boom, some ancillaries as well as the quick-attach carriage, joystick and some of the controls were carried over too. But they are far from being a clone of their forebears, despite these common components.

At the same time Claas took the opportunity to refine the model range and offer them solely in their seed green and red colours and only retailed through its dealers.

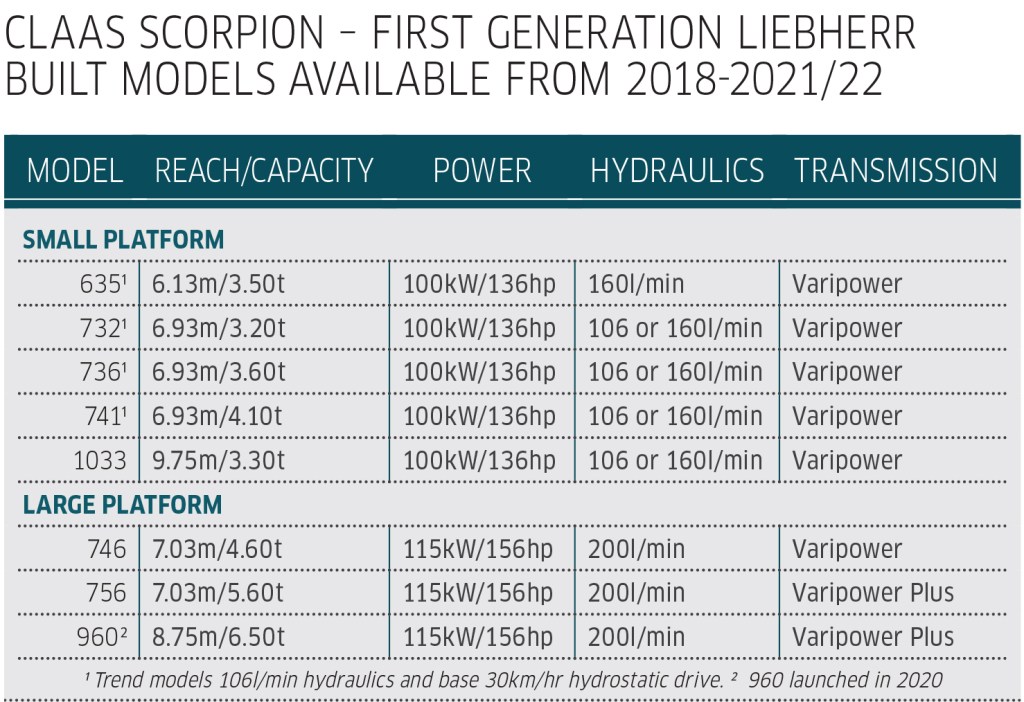

At launch, there were five ‘small platform’ models with standard power outputs of 100kW/136hp. Two ‘large platform’ machines were offered around 12 months later, one with the same 100kW/136hp engine as the small platform modesl and a larger 756 with the bigger 115kW/156hp from their Stage IV engines (see outline spec table).

The five smaller Scorpions were also offered with a simpler Trend specification with the same engine, but with a more straightforward 30km/hr basic hydrostatic driveline, basic joystick and 106-litre/min hydraulics – these variants have not been strong sellers in the UK.

In the new range was the 1033, this having a lift height of 9.75m and a rated capacity of 3.30t. The previous generation topped out at 8.80m, albeit with a rated lift capacity of 5.5t. During the summer of 2019, Claas extended the range, adding a further large platform model, the 8.79m reach Scorpion 960. This has a nominal 6.0t capacity at 600mm load centre or 6,500kg at 500mm.

Early Gen One Liebherr Claas Scorpion

The chassis and bonnet design for these current Scorpion models is completely different to the Kramer models, with the pivot point for the boom sitting lower on the chassis. The cab is also different, with the switches and controls rearranged around a central instrument cluster with a 3.5-inch display as standard, with a larger 7in screen showing all key functions listing as an option.

With reference to operation, Claas introduced its Smart Loading system with the most recent models. As you would expect, automatic overload protection is part of the package, with added functionality such bucket return for loading with a set bucket position control as standard. The speed of the hydraulics can be reduced by a half when carrying out work such as stacking pallet loads on large chassis on models.

NOTE: Previous Kramer generation models were offered with Smart Handling. This would automatically retract the boom when in bucket mode and extend it when raising a load in stacking mode. This useful feature was not initially carried over but was reintroduced for 2023 model year 746, 756 and 960 handlers and then to all models bar the 1033 from 2024.

Other features

Smart Roading is an integral part of the Claas Dynamic Power package. In broad outline, this element of the system automatically adjusts the engine output required to match the travel speed. On large chassis models, Dynamic Power will also regulate the engine speed in relation to joystick movements. The claim is these systems can save fuel and reduce noise.

In addition to front, all-wheel and crab-steer modes, manual crab-steering mode was also added. This allows the front axle to be steered with the rears set at a fixed angle. The aim is to allow eased steering when compacting the edges of clamps or moving along the walls of buildings. As to tyres, 741 and 736 handlers can be fitted with larger 500 profile rubber. Claas Telematics was also introduced for all models.

Proven elements carried over

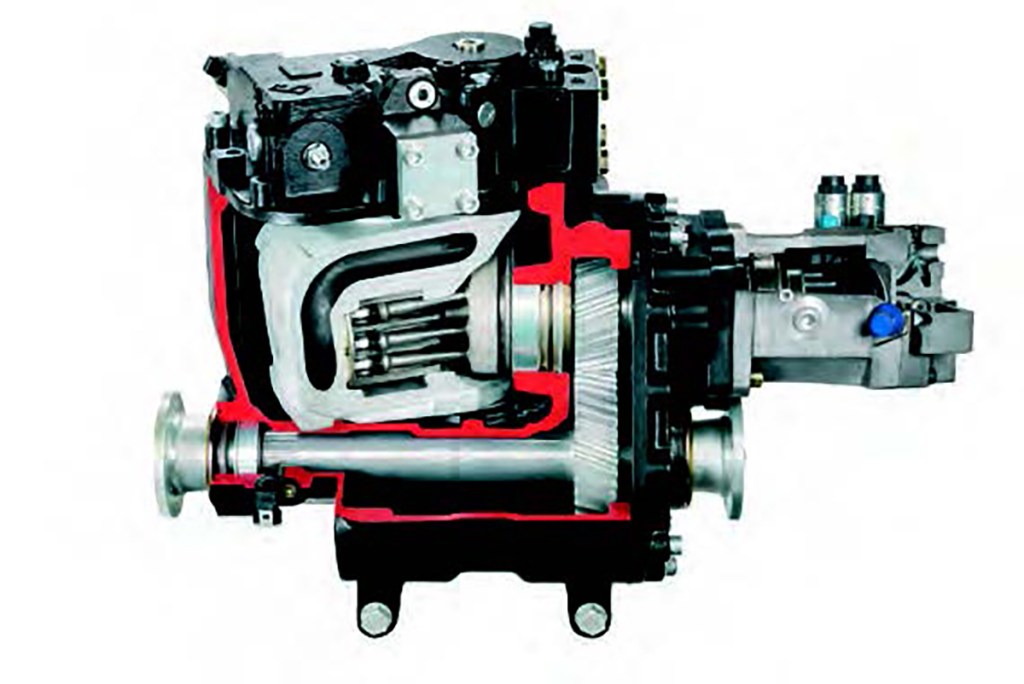

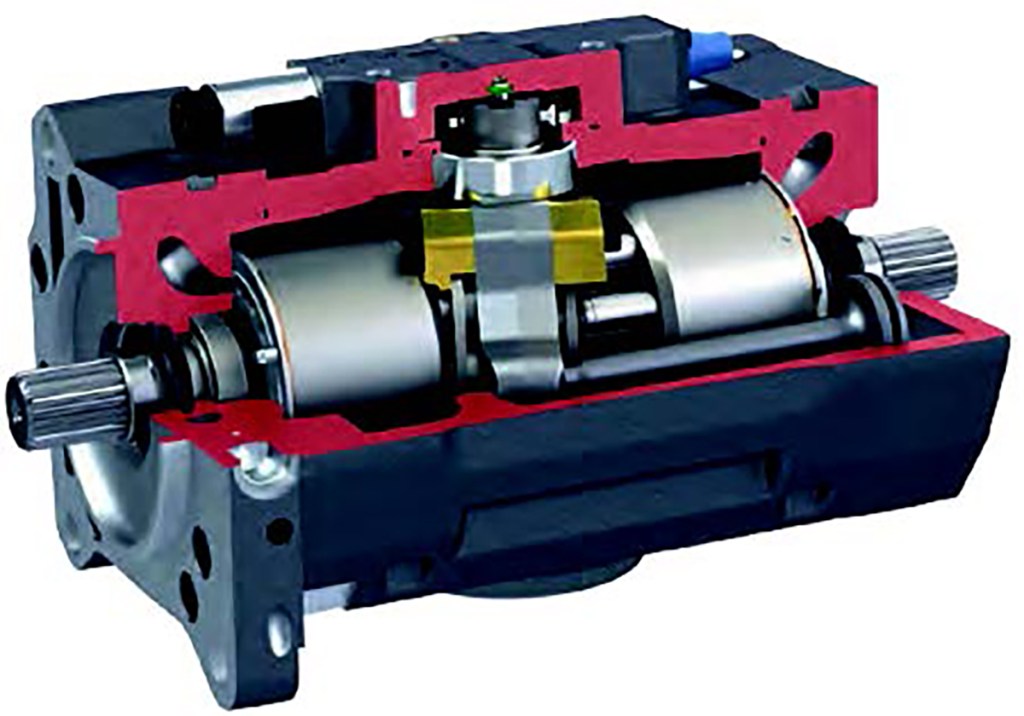

As previously mentioned, Claas and Liebherr retained the three speed Varipower and Varipower Plus transmissions and Deutz Stage IV engines. The 40km/hr Varipower Plus transmission has the same main 45° wide-angle hydrostatic pump as the Varipower but with a second 32° variable displacement pump to provide greater tractive and pulling power. Bucher load-sensing hydraulics were also carried over. Remember, small platform Varipower models have 160l/min hydraulics, Trend spec having a lower 106l/min.

Specification refinements include an electro-hydraulic parking brake that is applied automatically when the driver leaves the seat, the machine stops, or the engine is switched off and releases when the drive pedal is pressed. A ‘small’ change but a big deal if you are frequently jumping on and off the handler.

Other subtle tweaks include how the engine is cooled, Claas adopting a system that controls the fan speed to match operating conditions. An automatic reversing fan, with a manual control to boost cleaning when working in more challenging conditions, is standard in the UK and Ireland.

In a way, these changes are more likely to be seen as details. What about the more fundamental developments? As a used buyer, you may also want to consider a Kramer built Scorpion as there is a good park of these earlier machines. There are numerous differences, but the main ones are how the boom is mounted, the bonnet design and general layout of the cab and controls.

Scorpion developments and range additions

Claas showed its new generation of Scorpion models back in 2017, but various delays meant it was not until late 2018 that the first models started to appear with dealers, Kramer-built models remaining available into 2018. To further muddy the water, some of the earliest Liebherr built machines would have been sold alongside 2020 model year variants due to the movement of machines during the pandemic.

2020 Scorpion and all later machines meet Mother Regulation 2 compliance. An easy spot is the fitting of side marker lights and reflectors. The fuel tanks are also made from plastic, with a revised filler pipe on small platform models to ease topping up. A free flow return hydraulic pipe was made available on all models too.

Other detail changes to small platform models saw a new pressure load hold valve. JCB Q-Fit headstocks were also offered as a factory fit option.

2021 model year and Varipower 2

A number of a big change were made to small platform models with a switch Varipower 2 that is similar to the transmission used in Jaguar forage harvesters. This features dual hydrostatic motors sharing a common shaft and swash plate. Both motors are controlled via a single oil distribution unit, to reduce complexity. There are three ‘ranges’, as with the outgoing Varipower system, with speeds of 0-15km/hr, 0-30 km/h and 0-40km/hr. A key change is that the upper speed in each ‘range’ can be reached at a reduced engine speed. Varipower 2 also does away with the need for transfer gears, with the housing oil continuously extracted from the drive to reduce churning losses when driving at speed. Claas claim Varipower 2 reduces fuel use and has improved wear tolerances for an enhanced service life.

NOTE: The large platform 746 retains the Varipower transmission, with the 756 and 960 sticking with Varipower Plus.

Other detail changes are niceties as opposed to anything major. These include improved camera options, a four-digit load counter, LED flashing beacon and self-cancelling indicators.

Gen Two 2023 model year – further nips and tucks

Another year and further developments. Small platform models saw the Deutz Stage V, 3.6-litre engine power increased by a modest 6hp to 142hp, but more importantly torque climbed by a useful 10% to 50Nm, with the first of the three Varipower 2 speed ranges changing from 0-15 km/hr to 0-20 km/hr.

A point some users had commented upon was oversensitive, grabby braking. Claas sought to resolve this by fitting a revised system with a change in valves, a new brake pedal and some software tweaks.

All models from this point were fitted regenerative hydraulics with load-free lowering independent of engine speed. The pressure relief system for attachments was also tweaked on large chassis models to ease implement changes.

Moving to the cab, the air conditioning system saw an upgrade to increase air volume and boost performance in hot conditions. A new steering column, with automatic indicator reset, offers a wider range of adjustment, with the steering mode switchover improved.

2024 Gen three more change and models

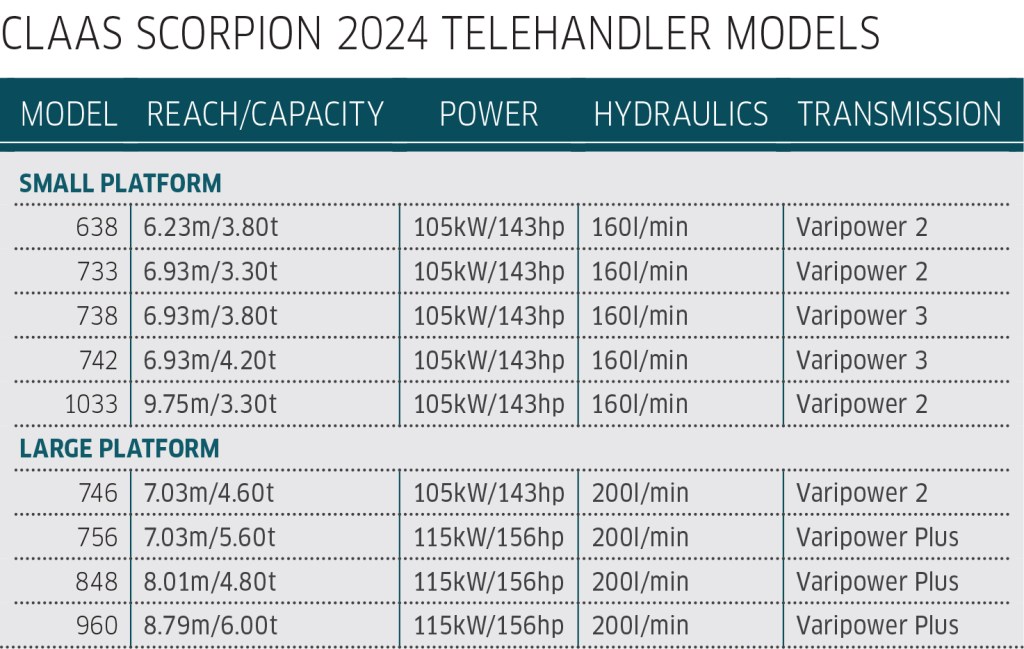

In brief, Claas made some significant developments for the 2024 model year, with five revised standard wheelbase models, with different numbering, in the nominal 3.0 to 4.0 tonne category.

- 732 (3.20t) replaced by the 733 (3.30t),

- 635 (3.50t) and 736 (3.60t) morph into the 638 (3.80t) and 738 (3.80t),

- 741 (4.10t) becomes the 742 (4.20t).

There are no modifications to the rear counterweight on the new models instead their wheelbase increasing by 100mm to enable the capacity hike.

Control wise, the Smart Loading system was updated, with revised hydraulic controls with electronic pilot control. Automatic functions and assistance systems now include:

- Automatic bucket return to saved position

- Auto-bucket shake function

- Auto-boom retraction (not on the Scorpion 1033)

It was not all about lift, developments including a higher tractive force Varipower 3 transmission for the 738 and 742 were also introduced. Although based upon the existing Varipower 2, Varipower 3 features larger dual hydraulic motors with 68kN tractive force delivered to the wheels. This is 20% up on the 57kN produced by Varipower 2.

It was also all change for the standard wheelbase models 3.6 litre engine, Claas switching to a 105kW/143hp, 550Nm Liebherr engine. This is tuned to deliver a maximum of 160l/m hydraulic output at 1,600 rpm.

The cab of small chassis models was also revised, with a much larger air conditioning system which now has its controls at the front of the dash rather than behind the driver. An ergonomic step up is the arm rest mounted joystick. A new top door catch allows the top door to be shut from outside the machine, and it sits flusher to the side. Inside, there are stowage compartments and cargo nets inside of the door and sound insulation in the door is also increased.

It follows that these later model developments will not be available to you yet as a used buyer and is a point to note if you are using a current spec sheet for your used buying research.

What to look for

Condition and specification are obvious starting points. It then follows that there is no such thing as a typical used telehandler, past use and care making it impossible to outline what to expect from a used buy. Although hours are a useful starting point, how those hours have been racked up is of equal importance.

With more direct reference to a Scorpion, it fair to say some of the earliest Liebherr examples may have needed a bit of attention to resolve some teething problems. Most were sorted out and should not now be a concern on a used buy. Fierce brakes and an over-fast reaction to joystick inputs is something to watch out for, but is less likely to be a problem on a used buys due to a field re-work campaign.

Other issues could include exposed electrical connectors, but these too should have been sorted out. A few software gremlins could cause the odd headache for dealers. Claas and Liebherr made numerous tweaks to these machines over a relatively short period, and it is partly this that makes it difficult to list potential ‘watch out for this’ comments.

If this suggests you need to tread carefully when considering an early production machine, it is meant more that some of the problems you may have heard about are ones that were resolved by various updates. Early small platform range models may have had the odd niggle but nothing major.

Larger platform models have a wider range of differences than you might think, and some examples may have had a few more gremlins to resolve, the 746 proving less dependable for some in the livestock sector but was fine for other users. If a 746 is on your used buying radar, seek advice, particularly if buying through a non-Claas dealer.

Boom and headstock

Liebherr clearly paid a lot of attention to build strength, with problems with the boom and chassis relating to pin and pivot wear as opposed to anything to do with the main structure. As with all telehandlers, alternative carriage designs will have been offered when new, but the Claas design has proven popular with an increasing number of models having it fitted. If you need an alternative, check the cost to swap.

Auotlube is a common fit, this talking care of the key boom pivot points but not the carriage as you would expect.

Tracking, track rods and tyres

It is simple to pick up wear in the track rod ends, or it at least it is if you can get someone to waggle the steering wheel whilst you look for movement at the joint. A key check is to look for even tyre wear across mainly the front axle, poor tracking causing wear that is often talked about but often just ignored. Claas improved the auto alignment between steering modes but still swap between them and check the wheels correctly align when you revert to rear and front only steering.

As a used buyer, you will inherit the tyres fitted by the previous user, block patterns proving a popular choice with those doing more yard and road work. Small platform handlers have fully locking front differentials, with limited slip front fitted to the larger model axles.

Engines and transmissions

It is tempting to suggest the main engine checks are simple; look at the oil and see if OEM filters are fitted and ensure the header tank is topped up to the level with clear coolant showing. Looking for a dirty exhaust used to be a key check too but Stage IV emission regs should mean that black smoke is only evident if the engine has serious problems. A dealer prepared used buy should be fine.

When it comes to the transmission, problems are more likely to be age and wear related, with dealer servicing typically ensuring problems with the Varipower and Varipower Plus units are unusual. The only way to test the transmission is to get it good and warm and then put it under load.

Cab and controls

A quick look in the cab can tell you a great deal about the machines past use. No amount of cleaning will be able to hide a hard worked livestock machine from its past, although the trim does respond well to an in-depth clean by a dealer’s valeting team. Key wear points are door seals and seat pans.

There are differences between the standard specifications of small and large platform models but as a rule all variants in the UK will tend to have everything you would expect to include a raft of work lights. LED items, incidentally, are not standard across the older models so check what is fitted.

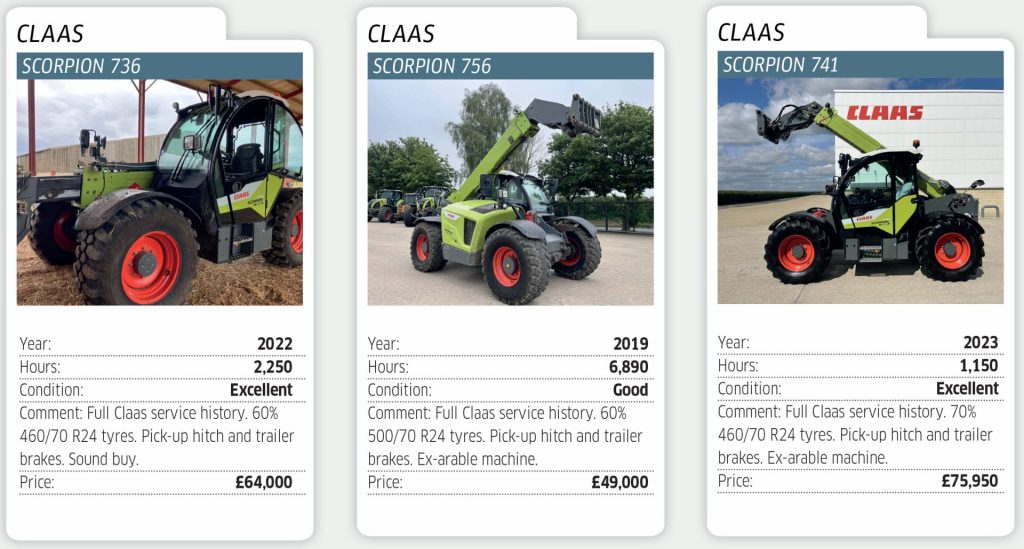

What about prices?

The three key used handler pointers are much the same as any item of kit. Condition, spec and hours are key. But the fourth is increasingly King. A full dealer service history. If a used buy has a solid record of past care, it really helps solidify the machine’s residual value.

Late Kramer and early Liebherr Scorpion prices can be close if in like for like condition and with similar hours. You can pay less for scruffy examples or those sold outside the Claas dealer network but £50,000 is a good starting point for either. Some models, such as the 741, are popular machines, with 2019 models showing under 3,000 hours possibly commanding as much £75,000 if in excellent order. A similar sum can get you into the seat of a 2021 736 showing a little over 1,000hours but perhaps this will apply to a machine that will not ‘look’ as good.

Summary

Liebherr built Claas Scorpion telehandlers entered their third generation for the 2025 model year, the more obvious developments not covering some of the detail changes made between the generations to resolve the odd problem or enhance performance. As a used buyer, you may have concerns that an early machine will therefore be more prone to future problems. This shouldn’t be the case. Many of the bits that you may think are a worry item are not new to these Scorpions and have proven in previous Kramer built generations. Those elements that could cause a problem will typically have been sorted out with various dealer updates.

What Claas couldn’t get around was the supply problems of five years ago. This is part the reason why the selection of these Scorpion models is so slim.

With thanks to: Tim Smith and Richard Sharman, Claas Eastern, Sleaford, Richard Charman, Claas Western, Cirencester and Will Riddleston, Manns, Saxham and Michael Ives, Claas UK.

James de Havilland

For more up-to-date farming news click here and subscribe now to profi and save.