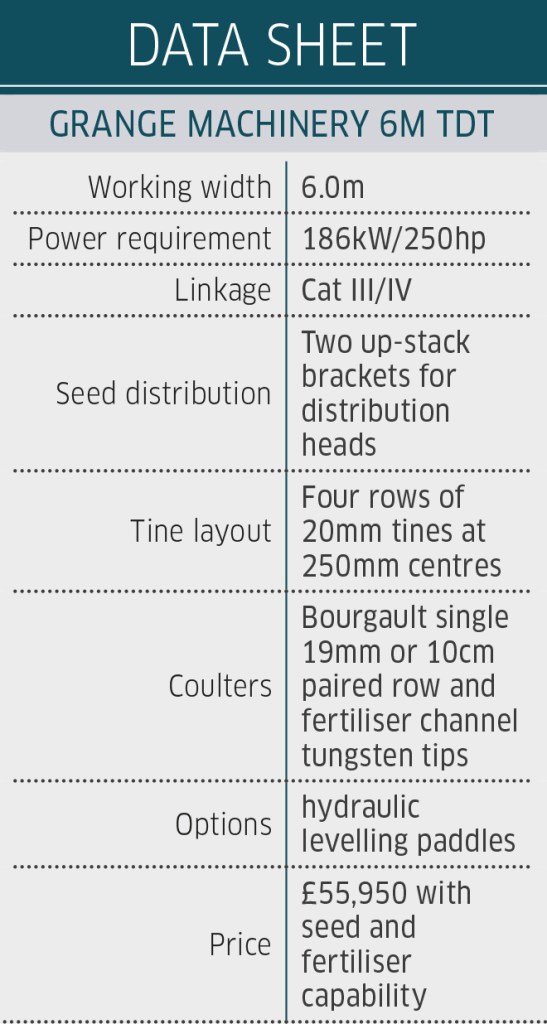

Customer demand for a tine drill has led Grange Machinery to develop the TDT with four rows of coulters. We caught up with the widest version, the Tine-Drill Toolbar 6m.

KEEPING IT BRIEF

- Available in working widths of 3.0m, 4.0m, 4.5m, 4.8m, 5.0m and 6.0m.

- Coulters and tips are sourced from Bourgault Tillage Tools UK.

- Can be used with most makes of front hopper, either as seed only or as grain and fert.

After another autumn that suddenly went from wet to wetter, dragging out the faithful tine drill when that high tech, pricy cultivator drill starts to block up with mud is becoming familiar. For those wanting a drill that offers modern metering and control technology and a lightweight design to allow it to continue to travel and place seed accurately as conditions deteriorate, then the Tine-Drill Toolbar (TDT) from Grange Machinery would seem to tick the box.

The TDT was launched at Cereals last year and the first production models have been working on farm this season. Based on the framework of the Grange Low Disturbance Loosener, which has been a popular partner for other drills and cultivators to offer deep loosening, the TDT is laid out as a front tank and rear toolbar design to offer optimum weight distribution.

Business end

Four rows of 20mm Grange tines fitted to the toolbar frame at a tine spacing of 250mm centres; working depth is up to 170mm, controlled on the hydraulically adjustable land wheels on-the-move. Each wheel has a pair of track eradicator tines positioned behind to remove wheeling marks.

“Tine spacing is designed to allow the drill to work in high levels of trash, with a ‘resting area’ in the centre section,” comments Rhun Jones, managing director for the Yorkshire-based firm. “We’re confident that the TDT can work in all conditions from cover crop residues to cultivated land.”

The design features contouring wings which have a pivot pitch of up to 6.0 degrees side to side integrated into the carrying frame above each wing to allow for undulations and varying terrain, maintaining seed depth across the full width of the drill.

The tine frame folds neatly for transport on models of 4.0m and above; front and rear combination drills have always been a popular option for farms looking for more output but with challenging access to fields.

Grange Machinery is working with Bourgault Tillage Tools UK for the supply of coulters and will be offering the full range of tips. The Bourgault 688-HLD-2000 holder and the 610-TIP-4030, four-inch paired row tip or 19mm single coulter are expected to be popular choices. This high chromium tip has a ¾in carbide nose tile which opens the seed slot and creates a drainage channel below where the seed is placed.

Coulters are followed by a double rear harrow frame mounted on a parallel linkage which is height and pitch adjustable and fitted with a Z tine harrow, or the preferred option, hydraulically adjustable sprung levelling paddles, with a further tine harrow to finish.

“We’re seeing increased interest for the TDT in one-pass systems and would recommend the levelling paddles in this situation to give the best possible finish,” comments Rhun. “For mulch or conventional seedbeds, the double harrow works well.”

On the move adjust

Hydraulic seed depth adjustment allows for easy and accurate change on the move with each of the centrally positioned land wheels having a pair of tines positioned equally behind them in the frame to remove all wheelings, leaving an even finish.

The drill can be specified with either one or two distribution heads for seed-only or a grain and fertiliser combination. Front tank specification is down to the customer and their supplying dealer, allowing them to use their preferred metering system.

“There may be an existing tank on the farm, or the customer may have particular requirements for the metering and control system for his crops and tractors,” explains Rhun. “We can work with tanks from all mainstream manufacturers and in the future we will offer a Grange front tank in both single and double metering system versions.

We will be working closely with another manufacturer on this with a proven tank and metering system.”

Further options include a rear access platform and seeder mounting bracket, Stocks Turbo Jet 8 I-Con seed applicator and rear bar fitted with seed pipes and outlets brackets for Avadex / slug pellet application.

“Most of the enquiries and orders have included the fitting of a second tank, and this offers further versatility for cover crops, slug pellets etc,” he says.

An LED road lighting kit is standard, along with depth adjustable track eradicator tine brackets to accept Grange or other manufacturer eradicator tines.

Jane Carley

For more up-to-date farming news click here and subscribe now to profi and save.