A thorough check of a combine’s bearings can help to ensure you have a trouble-free start to the harvest, with a much reduced risk of frustrating downtime.

KEEPING IT BRIEF

- Bushed, roller and plain bearings all have one thing in common. They wear out.

- Recognising wear early is key. You may see it, hear it or feel it as play.

- Certain bearings should be replaced at fixed intervals.

- Some bearing manufacturers list service lives and maintenance schedules.

Replacing a damaged bearing can be relatively straightforward and not overly expensive, so it makes sense to detect wear before it becomes a costly problem. Everyone is familiar with the in-field hassle associated with a worn bearing, be it through excessive vibration through to overheating leading to a machine blaze.

The German harvest repair specialist Quinte maintains, repairs and sells used combines, with workshop foreman, Markus Ernst, and company co-owner, Michael Katt, setting out some tips in spotting rogue bearings.

Causes of damage and wear

Some bearings can last the life of a machine. All they need is diligent care and regular lubrication, though it can be best to replace some bearings as a routine service job.

“Based on past experience, we recommend replacing some rotor bearings every four years on certain combines averaging 350ha/year. Do that and they won’t give problems,” says Markus Ernst. “Every make and model of combine will have known check points when it comes to bearings.”

There are several general tips to follow that can help minimise problems. These include taking care when washing off the machine. Although it’s obvious, directing pressure jet water at 200 bar at a roller bearing can lead to water ingress that no amount of running up the machine is able to disperse. Eventual corrosion is likely. If you do wash a machine down, it pays to lube all greaseable bearings immediately and run the machine up and let it idle for a while to help dry it off. If you spot rust spots around a bearing, it’s a sure sign that water has got in.

Bearings can also be damaged by electricity. If you ever need to weld near the threshing drum, for example, ensure the earth lead is clamped as close as possible to the weld area. This will minimise the risk of current flowing through a bearing. The latter can cause arcing inside the bearing that can lead to the formation of small craters on wearing surfaces, resulting in accelerated wear.

Avoid strain

New bearings can fail soon after they were fitted, typically due to incorrect installation or fitting a bearing that is not the right size. If a bearing is forced into position, its axial rolling resistance will increase.

Deep groove ball bearings can absorb up to 20% of axial loads but will suffer if forced into too tight an aperture or tight onto too large a shaft. Obvious, but easily done when replacement bearings look right but are not exactly right.

Also, knocking on the inner ring of a bearing during the installation may damage the races of the rolling elements or damage the seal. Even relatively small impacts may increase abrasion and wear.

Using the appropriate tool for the job helps. A suitably sized socket or special impact sleeve to fit the bearing shell can make it easier to seat a bearing. It is also important to check for free running when the bearing has been installed.

To minimise any problems, clean everything thoroughly. Shaft stubs and bearing housings may benefit from a wire brush or clean with sandpaper.

Optical inspection

To identify any worn or damaged bearings, particularly roller bearings, a visual check may help. Is any of the paint around a bearing showing signs of heat damage or peeling? Are the seals properly seated? Are there any signs of corrosion? Are all locking elements, such as clamp or snap rings in place?

If it is safe with the combine running, can you detect if a bearing is rotating as you would expect? If not, the cause will either be seized-up or sticking rollers due to poor lubrication, a worn bearing block or a problem with the shaft itself.

Obviously not all bearings are visible. It is here where an endoscope linked to a mobile phone can be useful, as these can be poked into inaccessible areas to enable you to see what is happening. These are available for under £20.

Detecting a bearing that is running hot is more involved. For a start, how hot is too hot?

“In continuous working operation, a bearing temperature of over about 70°C, such those running in the straw chopper unit, may be normal,” says Markus Ernst. “But it’s difficult to define exactly what is an unusually high temperature.”

That said, temperature differences between similar bearings may provide a reference heat value to help isolate a hot runner.

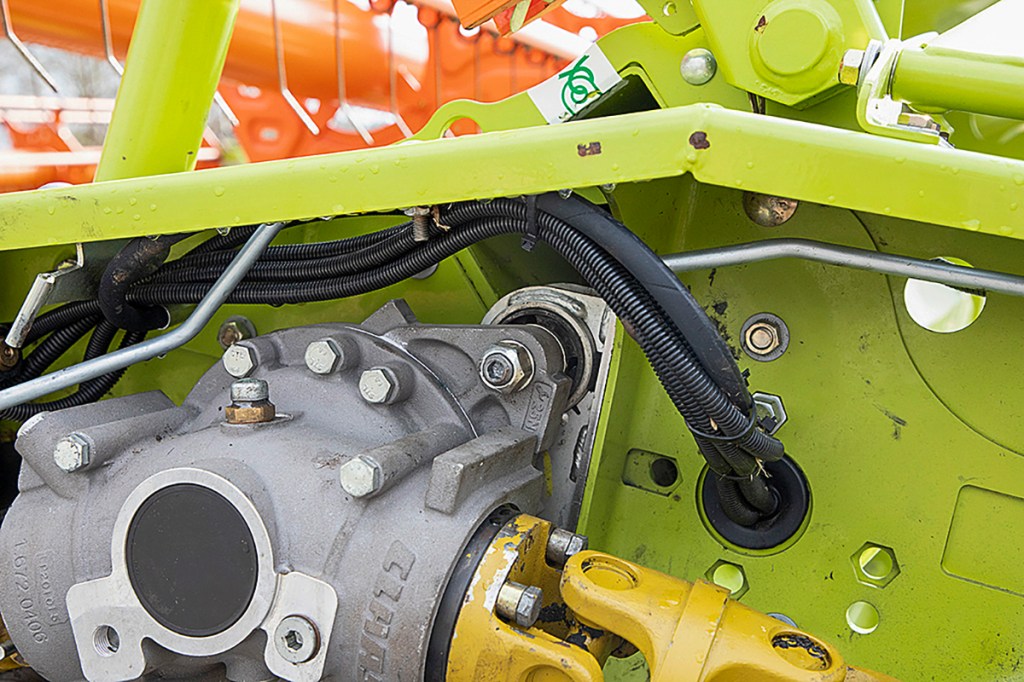

Vibration-damped rubber to metal bushes that hold belt tensioners in place or gearbox suspension systems are further wear items. Look for cracks in the rubber blocks and see if the bush itself is running true within the housing. If you can see a potential problem, it pays to renew the bush before it fails.

Noise testing

Metallic noise and vibration coming from a bearing is an obvious sign that something is wrong. The main difficulty comes in isolating where the noise comes from, the more so as most machinery is far from silent when it is up and running. No surprise that a damaged bearing is often only spotted when it is too late. An electronic stethoscope, with a long metal probe to access awkward bearings, can help you pick up the odd rumble, these items selling from around £40. You can add a nought to that for a professional unit, but a cheap design may be fine for occasional use. It takes practice to use a stethoscope, but these tools can pick up the initial signs of a bearing running dry once you have established what to listen out for.

If you are unsure about a particular bearing in a driveline, try to isolate the bearing by removing it from a gearbox or belt and rotate the related shaft manually. If you pick up running noises, or less than even running, at a low speed, then it is likely the bearing is on the way out.

Check for play

Bearing play is perhaps one of the more obvious checks. Bars, levers and bits of scrap can all be used to apply some force to a bearing to see if you can detect any play. A roller bearing should have no noticeable play, so, if you notice even slight movement, replace the bearing.

Much the same will apply to almost all plain bearings and bushes … with exceptions. The hardwood plain bearing blocks on some straw walker combines should have some play or they can seize. Lateral play may be reduced using shims, but, in these instances, you will need to check a service manual.

Further aids

Bearings have been around for a very long time, with measuring instruments used in industrial applications also used to determine the condition of bearings in heavy plant.

These include ultrasonic devices that work by attaching a sensor on to the bearing to record running noise. This is then compared with reference ISO values, a bearing running at 8dB above suggesting a lack of lubrication, 16dB damage and 35dB a sign of failure.

Such monitoring is outside the scope of a typical workshop, but it does illustrate how checking a bearing as it runs can be used to determine if it needs further attention. As agricultural kit becomes more sophisticated, permanently installed temperature sensors are now likely to become more commonplace. To give just the one example, the Kemper C250 TLA ProfiCracker unit incorporates a temperature sensor that can flag up when a particular bearing is running hot and should be replaced.

Summary

Combine harvesters and a host of other bits of kit have numerous rotating and oscillating components. Thorough inspection ahead of harvesting is an established must, eased if you follow a few basic tips. Thorough visual checks, a good ear and a few levers can help detect a bearing problem before it stops you in the field.

Bearing and belt damage at a glance:

DEFECTIVE SEAL

MOISTURE DAMAGE

DAMAGED BEARINGS

LACK OF GREASE

Dirty grease

CRACKS CAUSED BY OLD AGE

WALKER BEARINGS FROM WOOD

WHILE YOU ARE AT IT — CHECK THE DRIVE BELTS

Alexander Bertling

For more up-to-date farming news click here and subscribe now to profi and save.