Not every farm will have an excavator. But, once you have one, you’ll find more and more jobs you can do with it, even if that means being extra creative in the farm workshop to manufacture or modify various attachments. Here’s a selection of what’s possible … along with some other digger delights.

Excavators are versatile buddies and useful for stacking bales, splitting wood, mulching and loading the muck spreader. Kitted out with the right implements, they’re often faster and more manoeuvrable, especially in tight spaces, than front loader tractors or a wheel loader. In addition, they can go about their business without shunting back and forth all the time, a particular plus point in sticky conditions — especially if the machine runs on tracks. The following tips highlight mods and retrofit solutions that can upgrade an excavator for agricultural jobs. Happy reading.

Alexander Bertling

BUCKET IN REVERSE

This reader turned a handling bucket on his wheeled excavator 180° and uses it now for loading muck and, in the barn, for loading grain and fertiliser. With the bucket in this position, he can push bulky, flowing material up against the wall and pick it up from there, rather than pulling it towards the excavator. The dump angle is still good enough for loading material at even 3.50 metres. The bucket is bolted to the carriage and holds 400kg of grain.

SIMPLE BOTTLE HOLDER

Excavator cabs are usually cramped, so this reader was looking for a way to store his bottle in a safe place. The holder is made of a steel bar that he folded and bent and then hooked it to the trim of the cubby tray behind the seat. This way, the bottle won’t roll about.

LET IT RIP

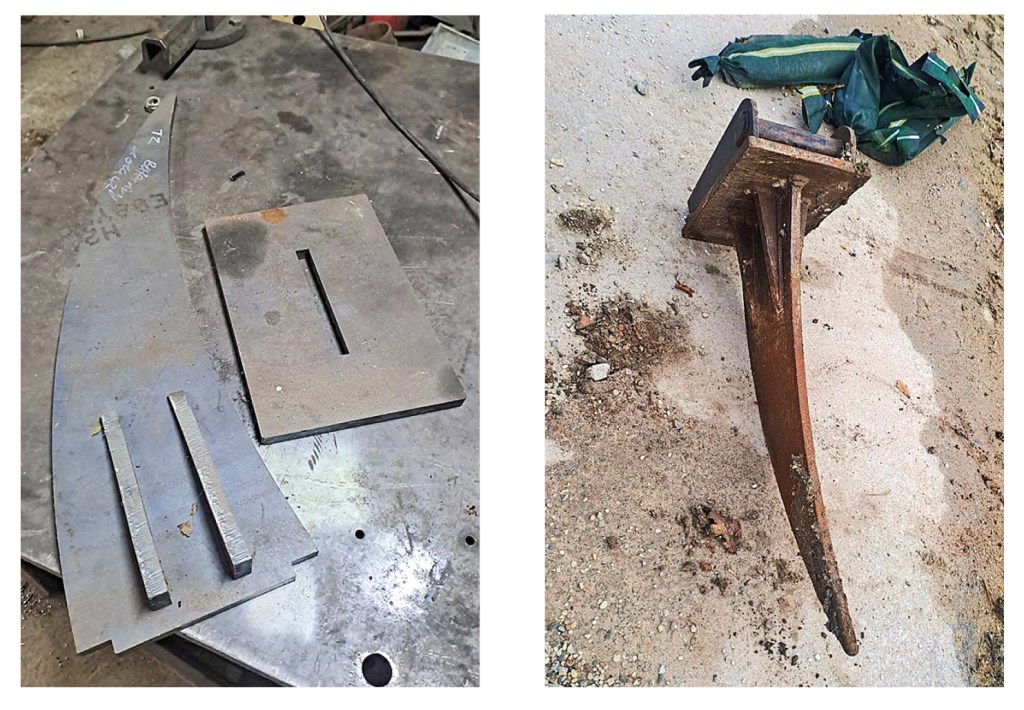

This reader uses a 90cm ripper for all types of work including demolition and removing roots. It features an MS03 mount, and the steel is 20mm thick. For cutting out the necessary bits, the owner called an engineering firm he knows very well. He inserted the tooth into the mounting, welded it all-round and then reinforced it with gussets. The solid construction has held up so far, even though the tooth is only made of regular mild steel.

PILE DRIVER

The same reader located some thick pieces of scrap steel to make an adapter for his hydraulic-powered rock breaker, which he uses to drive in fence posts. The adapter is attached to the chisel.

HOSE RACK

This owner frequently swaps attachments so he knocked up a frame from four squared lengths of timber on which he can safely store the grab in its closed position. He also added a hose storage rack made from a sheet of folded stainless steel into which he cut semi circles. These circles host the grab’s hydraulic couplers so that they no longer drop on the ground.

STACKING ON A SWIVEL

This reader calls on his Kramer wheeled excavator for various loading jobs. For maximum versatility, he created a self-built adapter plate that picks up the attachments. Going with the excavator for stacking bales has proved particularly efficient, because the machine can place up to six round bales into a small space without ever having to turn a wheel.

EXHAUST FUMES UP AND AWAY

This reader was bothered by the low-mounted exhaust pipe on his mini excavator, particularly when trenching and laying pipes when the fumes were directed into the trench. To overcome this design flaw, he ran a flexible exhaust hose up behind the cab, fixing it with three brackets. The hose is only attached to the exhaust when emoloyed on specific tasks.

MULCHING AND FORESTRY WORK

This owner fits a hydraulic mulcher on his excavator to keep drains and ditches clean. The rotator adds extra practicality as it allows the operator to work in all directions. This does require an extra auxiliary circuit. For protection during forestry and mulching work, he attachs a cab guard, which can be removed when not needed.

IDEAL SPLITTER

For splitting firewood, this reader employs a cone splitter on a 3.5t excavator as well as an 18t vertical splitter with a combi-drive. To work efficiently and save energy as well as not tying up other machines, he constructed a holder with an A-frame. This is hooked to the blade of the excavator so the operator can take the log splitter (which is electrically powered) to the site.

At the same time, he has the cone splitter on the excavator boom ready for pre-splitting thick logs, converting this into a one-person job, even when splitting thick logs. As an alternative to the cone splitter, he occasionally uses a grapple with rotator, which is very helpful, making some jobs easier; it’s also easier on the back.

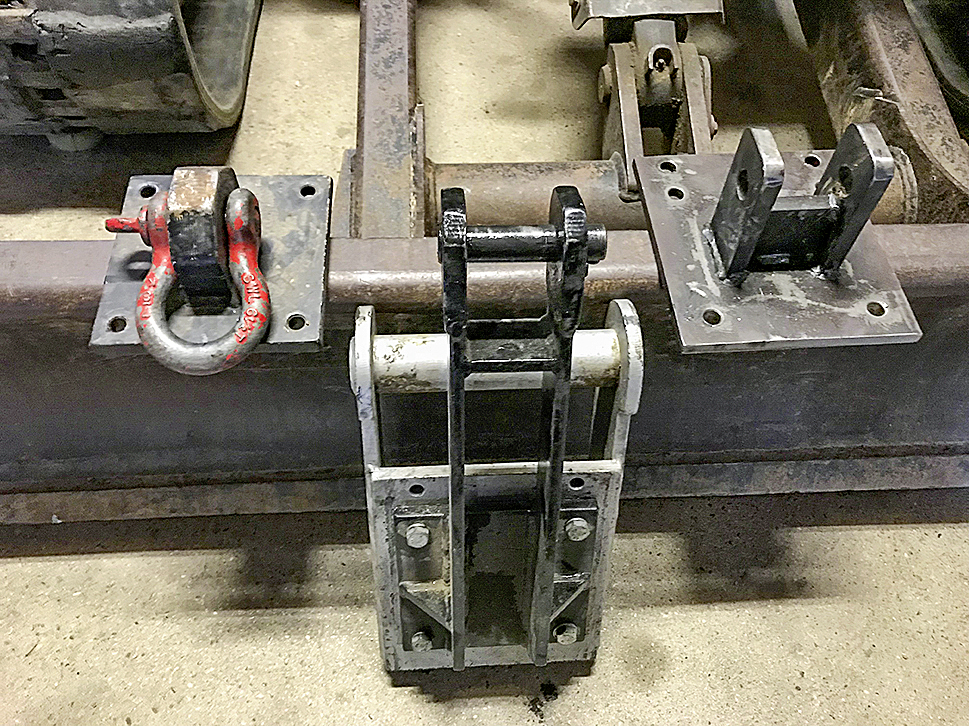

UNIVERSAL QUICK COUPLER

This reader built a universal MS03 quick coupler along with various bolt-on adapters that are fastened with up to six M12 bolts. Pictured is the adapter for a clamshell bucket, a swivel hook and a hitch for pivoting attachments (e.g. post hole diggers). It was a cost effective build made by a local fabricator and certified welder.

ROOF SPRUCE

Here is an operation that takes a delicate hand to avoid damaging vulnerable skylights. The owner of this rubber duck has a range of implements including this brush, which he can couple to with a modified Euro carriage. As well as keeping the yard swept he has also used the brush for clearing moss off several farm building roofs.

For more up-to-date farming news click here and subscribe now to profi and save.