The single-axle Supercis 1000 impresses with its low centre of gravity. But, in addition to the many positive details, there’s also some criticism of the Slovenian-made tanker.

KEEPING IT BRIEF

- Farmtech’s Supercis tanker impressed with many details.

- The tank itself is compact and stable on slopes.

- The tested combination is no bargain. There are lower cost alternatives for farms focused on just doing their own work.

Slovenian firm Farmtech has its work cut out if it wants to break into the UK and Irish market; with our own array of domestic makers, it could be akin to selling sand to the Arabs.

So, why have we included this test from our German colleagues? The tanker’s low-slung design and extra features are what made us raise an eyebrow when we read the Supercis 1000 test report.

This single-axle model with a useable volume of 10.2m³ (about 2,250 gallons in old money) is available with a vacuum or pump; the latter is a 3,000l/min Wangen eccentric screw unit located under its belly, and this is what was fitted to the test machine. It also came with its own 10.50m Condor trailing shoe boom applicator, which folds alongside the tank. This has a shoe spacing of 25cm; there is also a 12m unit with a 30cm line spacing available. Thanks to the narrow design of the tank (1.60m diameter, 5.37m length), the booms fold alongside the tank, a task that takes just 15 seconds.

The tank is fully galvanized, has 5mm walls and baffle plates inside. Farmtech also paints the entire barrel with a clear varnish. This makes it easy to clean, but the coating is also applied to the hoses etc. After six months’ work, you could very clearly see the varnish peeling off the hoses.

Compact dimensions

Due to the small diameter tank, it isn’t a problem that the shoes don’t lean tight up against the tank when in their transport position, as the overall transport height is just 3.35m high. Our machine also had the biggest tyre option, BKT 850/50 R30.5s, resulting in an overall width of exactly 3.0m. These tyres proved their worth and left a good impression both in the (wet) field and on the road. But they do come with a hefty €6,000 price tag over the 750 alternative.

Too heavy for one axle

When empty, the high-spec tanker weighs 5,850kg, of which a hitch load of 650kg rests on the K80 spoon drawbar. When fully filled, 12,200kg is on the tanker axle plus 2.8t on the tractor hitch. The height of the drawbar can also be adjusted hydraulically to suit different tractors, and the rams also double-job as dampers by being connected to a pair of accumulators for a smoother road ride. Likewise, the tank can be raised/lowered for filling and emptying. Excellent.

This latter function is particularly useful as the Supercis tank is emptied from the front. Our model was equipped with the electric comfort control (€6,760) meaning all of the hydraulic functions are operated from a control box and supplied with oil from the tractor’s load-sensing system.

The control box is virtually self-explanatory, except perhaps a few details, such as manual reverse for the macerator when the tank is empty, or that you can position the valves for the pump and outlet so you can use the tank also as a pumping station.

In addition to the three-way valve (pump, tank, applicator) our test machine had an additional manual valve that was connected to the applicator, but this could also be used with a splash plate.

Automatic level sensing

The fill level is indicated by a float, which has a sensor fitted on both ends. The sensor can be easily set to the right filling level using a wing nut to avoid overfilling and consequential mess in the yard. However, to make sure the float gives a true reading, you want to ensure the drawbar height is in the same position. We always used the drawbar in its fully retracted position, which worked very well for us. There is also an integrated LED light which shows that the tank is full. A flashing light to hint that the tank is near its maximum would be the icing on the cake.

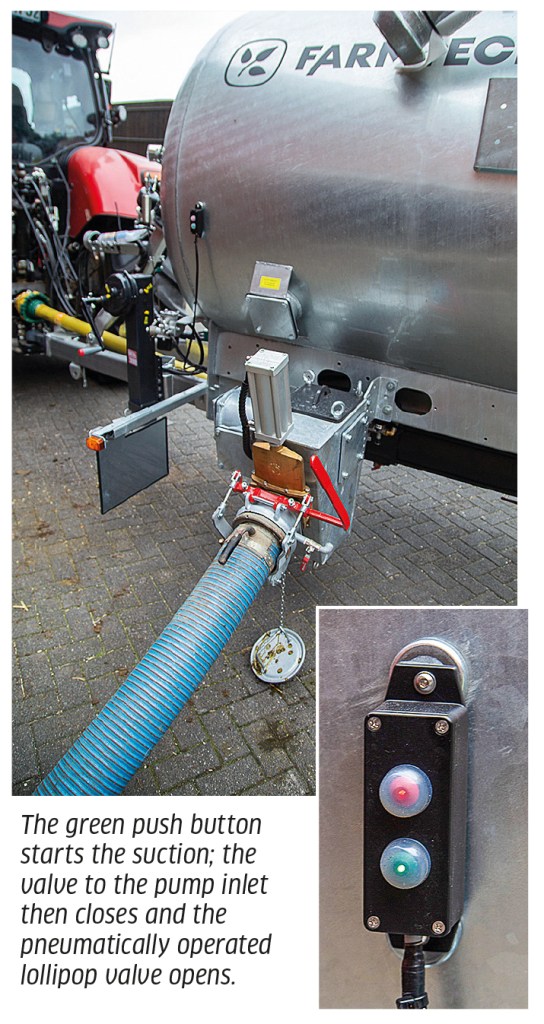

When the float reaches the sensor, the electronic system opens the pneumatically operated valve to the pump and closes the pneumatic valve on the 6-inch suction hose located on the left of our tank; the slurry then circulates. A small remote control, which is simply attached to the tank with a magnet, lets you start the suction process with a green button, and, if you want to do things manually, the red button stops it. Farmtech doesn’t actually offer a manually operated valve, as it says the automated approach prevents any erroneous operation.

Spreading slurry, we weren’t keen on this automatic level indicator. For instance, make a swift headland turn with the tank about two thirds empty, and the slurry obviously sloshes about; if the fill level indicator on the outside even temporarily signals to the sensor that the tank is empty, the valves automatically shift to their filling position despite a decent volume of liquid still being in the tank. You then need to manually reset it back to spreading before you can carry on. A little more inertia would be desirable for this sensor.

Trailing shoe applicator

According to the manufacturer, the 10.50m wide applicator weighs 950kg. The 5 inch inlet to the macerator should be better secured. With the valve fully open, we were able to spread 25m³/ha of cattle slurry at around 6km/hr — that’s fine.

We really liked the applicator — the shoes apply the slurry in narrow and clean bands, a tidy job. The good pressure on the shoes certainly helps here, which is achieved by a double-acting spool that pressurises the boom. There is no float position for the two lift cylinders. The boom can swing sideways by mounting the linkage in slotted holes. Buyers can also opt for a central pivot pin — similar to a crop sprayer boom.

Our only point of criticism here is that the tanker should ideally be stationary to fold the booms. Otherwise, they swing sideways hitting the tank. A small cylinder on the pins of the boom folding mechanism serves as a transport lock. One lock bent during use. Also, the folded booms are not really fixed tight on their mountings. So, if you want to be on the safe side, we recommend the transport locks for the mountings.

We did measure distribution across the rows to the DLG test criteria, and there were no abnormalities.

Other details

- A pressure gauge to show a blockage in the macerator is available as an option. Direction of macerator rotation changes automatically.

- Hydraulic hose routing and storage rack are good.

- No automatic headland turn sequence is offered.

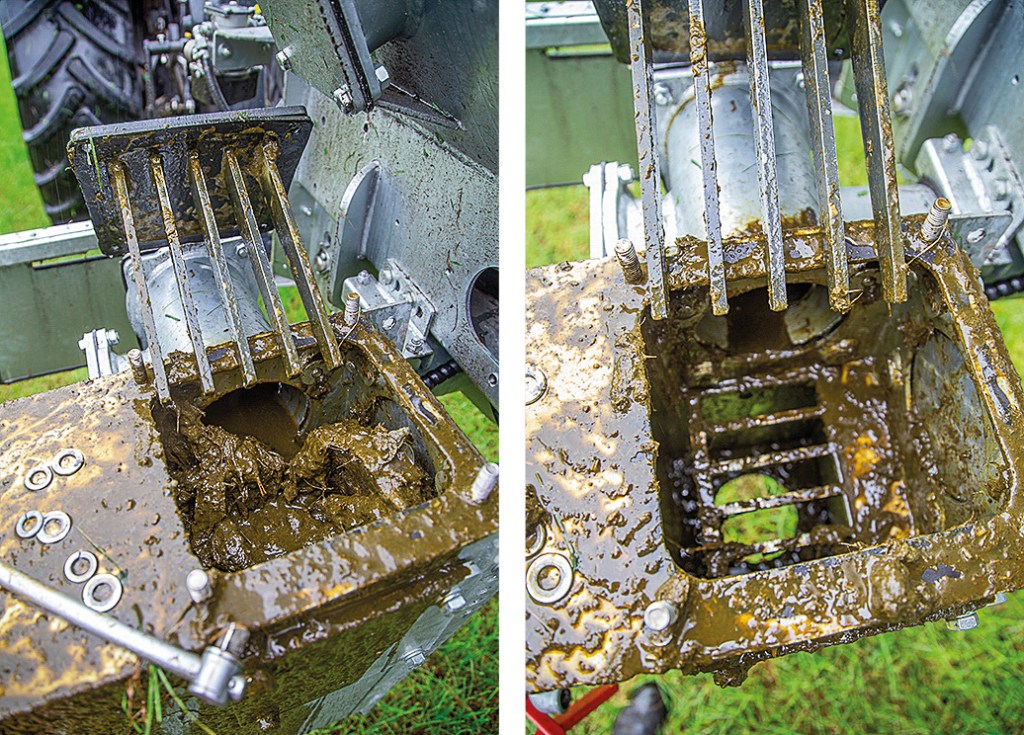

- The stone trap at the suction hose has a fork that effectively collects straw, tarp or wooden blocks. Cleaning it, however, does take a bit of spannering. A macerator is available on request.

- The pump’s suction power is impressive even in deep pits.

- The brackets for storing the suction hoses are too high for ‘normal’ people.

- The hydraulic valve block is protected. Unfortunately, one valve on our machine regularly jammed.

Summary

Farmtech provides its customers with lots of options. Our Supercis 1000 offered a low centre of gravity and was highly equipped with the 10.50m wide Condor distributor including full electro-hydraulic control. The Wangen pump ensured a consistent flow of liquid at high pressures.

We were largely happy with the controls, although we can still see room for a bit of fine-tuning. Auto fill functions are practical; however, for emptying, a simpler override function would be helpful.

Entry prices start at €42,000 and end in our case at a whopping €100,000 for the test machine — all list prices, mind. And this spec didn’t even include a self-fill arm.

WHO IS FARMTECH?

Farmtech was part of the Komptech Group, but a combination of growth and reaching manufacturing capacity at the Ljutomer site in Slovenia has resulted in five shareholders taking on Farmtech as a separate business. These shareholders include Han Brantner (Brantner Group is best known for its trailer production but is also involved in logistics and waste management); Martin Gahleitner from MG Group (commercial and construction machinery); Günther Pirker who has been managing director of Farmtech since 2020; and Heinz Leitner who was CEO of Komtech Group for 15 years until 2024.

Komptech will continue to manufacture Farmtech products until the end of the 2026, but trailer and muck spreader production will shift to the Austrian Brantner factory, while the slurry tankers will be made in Hungary. Farmtech plans on showing a new push-off trailer at Agritechnica.

Hans Brantner: “Basically, both brands have the same customers — farmers and contractors. However, the brands are different. Farmtech is known for its very good price-performance ratio. I see Brantner in the premium sector with its many equipment options. In the new company, Brantner is not the majority owner, so we do not make decisions alone. In my opinion, however, there will be no Brantner slurry tanker in the future either.”

Heinz Leitner: “Farmtech’s strategy is and remains to be a full-liner for tractor-drawn transport technology. This means that tippers will not be dropped from the product portfolio.”

Günther Pirker: “We started with slurry technology at Farmtech in 2017. We have cooperation partners in Hungary who manufacture for us. This works very well and we want to continue working with the partners.” The production of slurry technology will not be relocated to Brantner.”

Tobias Bensing

For more up-to-date farming news click here and subscribe now to profi and save.