Electrification has found its way into a full-size Fendt tractor, in the guise of the E107S Vario. But how has it been done and what does it offer, over and above its far cheaper and virtually identical diesel-powered stablemate, the 207 Vario? Time to don the insulated gloves and stand on a rubber mat.

KEEPING IT BRIEF

- Charge management is essential

- Dealers require heavy investment in training

- CCS2 compatibility for charging

If you thought the four-pot 620 was expensive in last month’s issue, then hold my beer. Fendt’s all-electric, 70hp E107S starts at an eye-watering £198,000 for the boggy-basic Profi-specification. And that’s before you tick your way through the options list, or choose the Profi+ model.

Adding front linkage and pto, plus a host of other goodies, including a loader that was sat on its parking stands, cranks the heat up to £236,720 for this featured example.

For those concerned about the reliability and longevity of the EV tractor’s components, there’s some security in the knowledge that Fendt will provide an eight-year, 8,000-hour warranty. Extended warranty costs £2.46/hour, pushing the eco-friendly tractor’s price tag over £250,000. Let that sink in.

Model choice

The E100 series comprises two models – the full-size, 2,163mm-wide E107S and the narrow, 1,278mm-wide E107V. Fendt admits that the E100 series is unlikely to find its way onto many farms. The 200-series on which this is based accounts for just 5.0% of the German maker’s UK sales, with annual numbers floating between 30 and 50 units.

But it does see new market opportunities among the amenity, sports turf, local authority, solar and industrial sectors for the electric tractor. The key attraction of course, is zero emissions, low noise, a projected 7.7tonnes of carbon reduction per annum compared to the diesel version, and a one third reduction in the cost of servicing.

We’re focussed on the full-size E107S, which is expected to be the bigger seller of the two. So how did Fendt arrive at this point? Quite simply, it chose to electrify an existing tractor, rather than opt for a redesign using electric wheel motors or create the ability to run auxiliary equipment through electrical power outlets.

“We had an existing package in our 200-series that uses our proven Vario transmission, axles, hydraulics, suspension and cab,” said product specialist, Phil Mattey. “All we needed to do was substitute the power unit.”

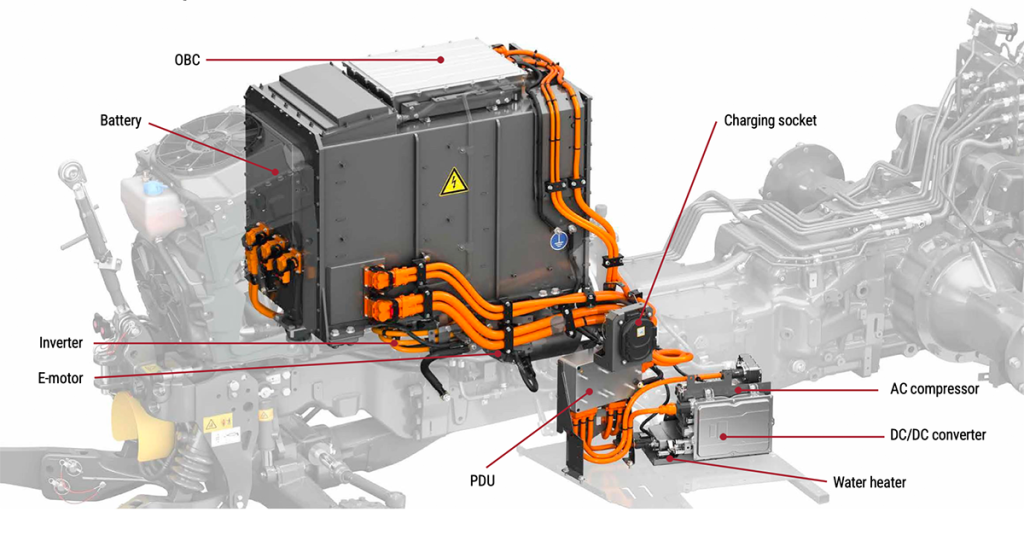

Taking the three-pot oil burner out of the 207 Vario and replacing it with a 100kW battery pack was the starting point for the E107S. Supplied by Bosch, the prismatic lithium-ion battery comprises 180 cells producing 668 volts and weighs around 650kg – just 150kg more than the three-banger diesel engine. The E107S weighs just 4,500kg, compared to 4,100g for the 207 Vario.

An inverter takes the 668-volt DC (direct current) output from the battery pack to provide AC (alternating current) to power the three-phase Danfoss electric motor, which is connected to the transmission input. Think of this as the engine’s crankshaft.

The AC motor is more efficient in power consumption than a DC motor, and it also provides flexibility over a wide range of working speeds. However, the AC motor’s high rpm working range is also responsible for the high-pitched whine that radiates from the tractor when in use.

However, this permanent magnet synchronous Danfoss motor runs considerably faster than the diesel engine would – typically up to 4,000rpm – so an epicyclic reduction gear slots between the motor and Fendt’s ML75 Vario transmission, to reduce the input shaft speed to a working range that replicates that of the diesel engine. This way, Fendt engineers can run the existing powertrain in the same speed range as the diesel equivalent.

This means the E107S has working speeds from 20 metres/hour up to 40km/hr.

In terms of power delivery, there are three driving modes available to the operator: Eco, Dynamic and Dynamic+. Eco creates 68hp, while Dynamic lifts this output to 75hp. Dynamic+ has the ability to deliver a peak output of 90hp, available for additional performance over a limited time, for example with high-load pto start-up.

The same, but different

In place of the diesel version’s floor-mounted exhaust brake is a foot switch for energy recovery. When travelling downhill, the foot switch can be used to put up to 40kWh back into the battery, making use of inertia. This retardation function also acts as brake.

A DC/DC converter is used to step-down the 668v battery output to 13.8v, to run the tractor’s standard 12-volt electrical system and its consumers, without need for an alternator. This is achieved using a power distribution unit, to direct energy where it’s needed.

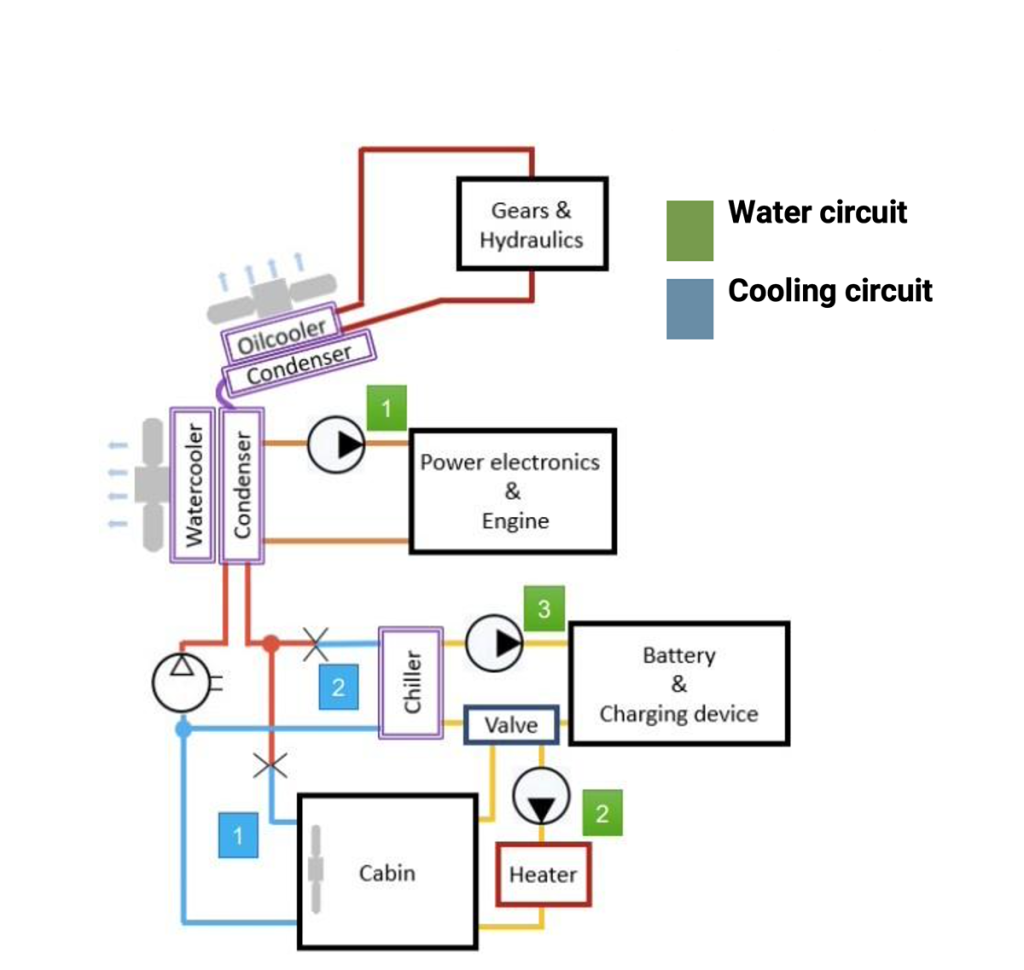

Fendt has had to work out different strategies for managing heat too, so the operator has little to worry about when using the tractor, and the E107S has three cooling circuits, which converge at the front of the tractor within a redesigned cooling package. Unlike conventional radiator packs that draw air in at the front and push it back over the engine, the E107S pulls air in at the sides and pushes warm air out through the front and top of the cooling pack. This avoids pushing warm air over an already warm battery pack.

Transmission oil is cooled conventionally through a radiator, with air flow provided by an electrically driven fan that sucks are forward through a condenser then through the transmission cooler. There are three water circuits built-in, which are used to manage heat among components and also provide a source of warmth for the cab.

A dedicated water circuit offers cooling of the electric drive motor, inverter and DC/DC converter. A second circuit provides cab heating, and a third circuit provides both heating and cooling of the battery pack. Both these circuits are connected by a series of directional valves, to divert heat where it may be needed, if it’s not being cooled.

Cleverly, waste heat generated during the charging cycle can also be used to pre-heat the cab, making the most of energy efficiency and recovery. An underfloor electric heating system also provides cab heating, and this too can be functioning when the charging process is operational.

Battery management

Charging the tractor is where an element of additional operator training and education may be required. Conscious of how mobile phone battery life can be shortened by repeated fast-charging, Fendt is keen to avoid the E107S’ battery capacity being eroded unnecessarily.

Fully integrated battery management helps to make the most of plug-in power, which creates multiple charge strategies that can be tailored to suit the way the tractor is being used. These include AC and DC inputs, with the later offering a rapid charge function using a 125-amp charger which is capable of firing a maximum of 80kW direct into the battery. This lifts charge status of the battery from 20-80% in just 45 minutes. Full charge on this system can be achieved in just one hour. A lesser 40kWh DC charge input delivering 64 amps slows the process to around two hours.

Far more sympathetic charging is achievable through AC charging stations. With a maximum 22kWh AC source for example, recharging takes around four to five hours, and is handled by the on-board inverter which then feeds the battery.

Fully topped up, the E107S can deliver a run time equivalent to 25% of what its diesel-powered stablemate can achieve on a full tank of fuel. So expect to become overly familiar with the many ways you can charge the E107S.

Through the FendtOne terminal, it is possible to select the charge current and charge times. This automatic charge management will finish charging the battery at the specified time, and also condition the battery by bringing it up to the correct operating temperature so it achieves a fully charged status just before it is due to be used each day.

This allows over-night trickle charging and cab pre-heating for example, which is said to make the most of battery life and maintain its total storage capacity for longer.

Daily maintenance requirements are few and far between on the E107S. Aside from inspecting and cleaning the cooling package, plus checking the oil levels, there is little to do but poke the grease gun around in the usual spots.

Orange cabling highlights the tractor’s high-voltage systems, which is anything over 30 volts AC and 60 volts DC. This in itself will require specialised technical training from dealers, with IMI Level 4 standard being applied to match that of the automotive sector.

So only the panels around the cooling pack can be opened – the bonnet remains firmly locked closed, and is accessible only by trained and qualified technicians.

In the cab

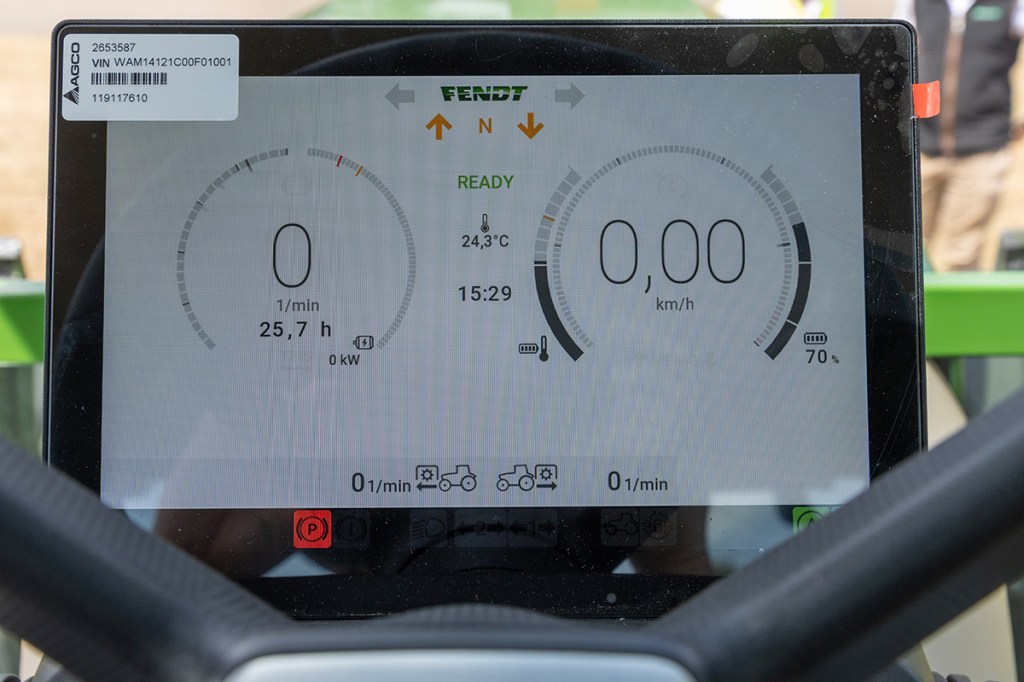

Anyone who has used the current generation of Fendt tractors will find the E107S no different. There is an ignition key, but it doesn’t turn. This individually coded key slots into a magnetic holder, so the electronic system can wake-up and identify that the correct key – and user – is at the controls.

A start/stop button on the steering column brings everything to life and the central instrument display nestled behind the steering wheel illustrates battery capacity and battery temperature.

Fendt’s joystick and terminal, plus pto and hydraulic functions, have lost no performance or functionality. There are two hydraulic circuits with up to six auxiliary services, plus Power Beyond and flow rates of up to 65 litres/min thanks to a 110 litres/min load-sensing hydraulic pump.

Rear lift capacity is 4.2 tonnes, spools can be assigned by the operator and flow rates can be individually set.

With the handbrake released, you’re good to go. Don’t expect any noise though, other than the whining of the electric drive motor.

EV REGULATION

Aftersales support will be a vital part of the E107’s introduction, with dealer technicians required to have a level of electric vehicle-related training recognised by a UK body, such as the Institute of the Motor Industry (IMI). While there will be specialists in the network with IMI Level 4 training, Fendt says dealers will receive IMI level training specific to the E100-series.

EV infrastructure can be provided by AGCO, to include safety equipment, workshop tooling and charging accessories, such as rubber floor mats, insulated tooling and the need to provide a one metre cordon around any EV in the workshop.

Summary

The arrival of the E100-series will put the German maker on its own diversification path towards new market opportunities beyond agriculture. Rather like large-scale industrial and construction projects like HS2 and its processes, this appears much more of an industry solution for blue-chip clients and customers who seek box-ticking for sustainability and environment, over cost and common sense. This aside, Fendt sees its future fuel sources being a mix of technologies, with batteries being used for low power applications typically sub-100hp, with the 100-250hp sector being driven by hydrogen. Above 250hp, E-fuels are likely to be adopted, including HVO.

Geoff Ashcroft

For more up-to-date farming news click here and subscribe now to profi and save.