…is how this generation of Vario 900 is often referred to, because of its front grille and headlights. But don’t let that put you off. This era of Fendt from the early 2000s combines both power and comfort.

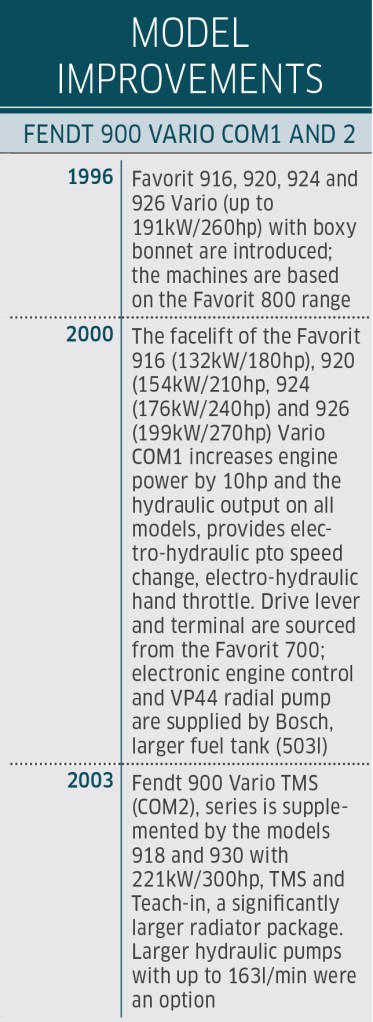

The facelifted first-generation Fendt Favorit 900 Vario range (otherwise known as COM1) was only produced for about three years and is often overshadowed by its older Favorit siblings and also its replacement, the COM2 models with TMS.

In 2000, these curvy bonnet models with the frog-eye headlights replaced the Vario originals, the Favorit 900s, which had been launched back in 1996. The rounded styling shared the same Vario family look with the smaller 700s which had come out in 1998.

But it wasn’t just natty exterior styling they shared; the 900s also gained the same multi-function armrest with the drive stick with Go and End buttons, plus the familiar colour VarioTerminal display. However, it didn’t have the Tractor Management System or TMS, which introduced automatic engine-gearbox control. You used the foot pedal to accelerate and controlled the transmission from the drive lever.

A 900 with heart and soul

Axel Schnackenberg knows these Favorit 900 Vario models inside out. A full-time industrial mechatronics engineer, he also runs a small contracting business that also rents out machines. Based in the German northernmost state Schleswig-Holstein near the Danish border, he is well-known to Fendt fans from his YouTube channel ‘Schnacki zeigt Lohnervlogs’. There he gives repair tips to over 80,000 subscribers and explains the technical features of these modern classics from Marktoberdorf.

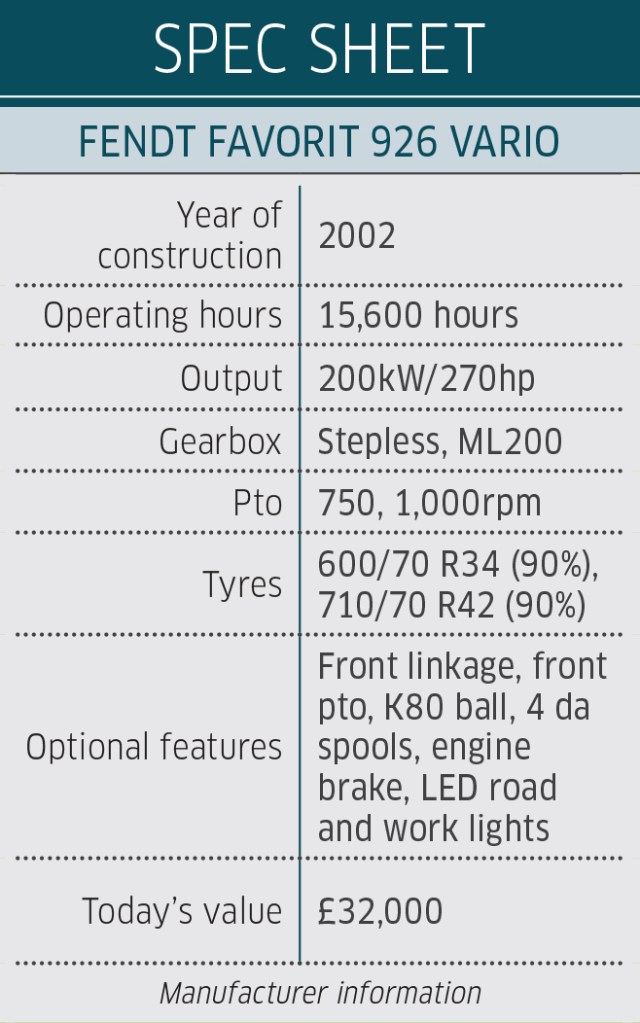

Six years ago, a 2002 926 Vario COM1 with around 15,600 hours on its clock found its way into the Schnackenberg fleet.

“I was drawn to the good spec including a front pto/linkage, retrofitted pneumatic cab suspension and engine brake,” Axel tells us. Yet, this 926 didn’t have the reverse drive, a popular option on these models. “Firstly, I don’t like the central tunnel on the floor, and secondly, with the 900 series, you can avoid a few potential problems, such as the increased risk of costly damage to the wiring harness under the cab.”

Brittle wiring looms are one problem with the 900s. Also, make sure all body panels are in place and preferably undamaged. Missing trim or parts such as the toolbox are often very expensive; that is if they are even available.

Under the bonnet

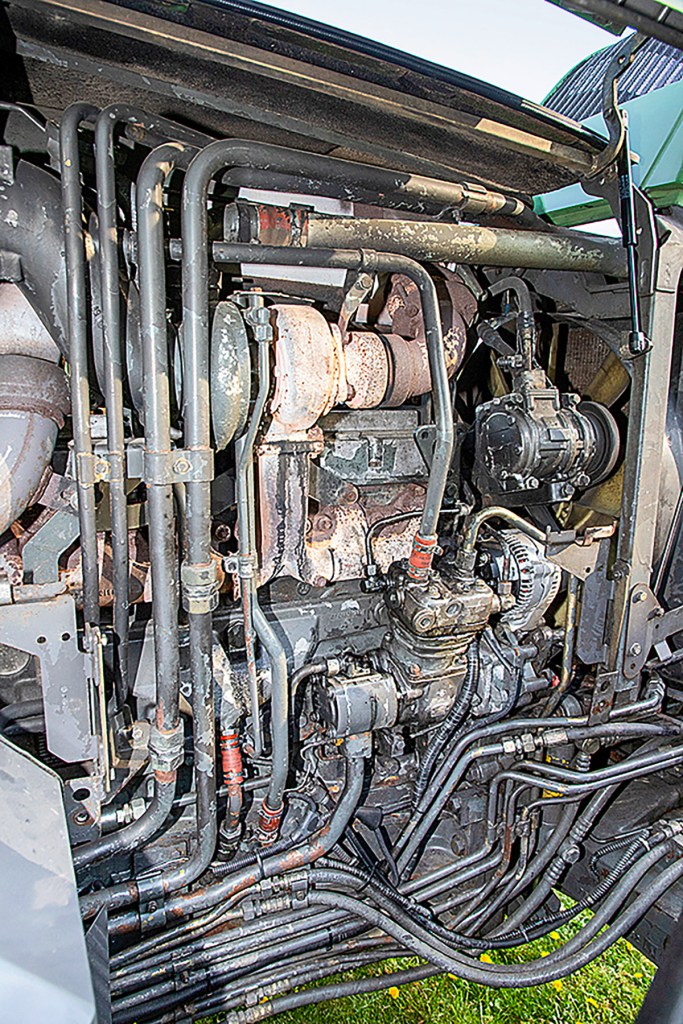

A verifiable service history is the cherry on top of the iced cake. But, if you don’t have that, it is worth having a good nose around. Take a look at the filters: is there any writing that shows the date of the last oil change? What type of filters are used? If these details are in order, you should be able to enjoy the robust, 6.9-litre MAN six-cylinder D0826LE for a long time. The rated power of the four models — 916, 920, 924 and 926 — ranges between 132kW/180hp and 199kW/270hp.

Occasionally, the cylinder head gasket can fail if the tractor overheats when under load. Heavy field work can highlight the lack of radiator surface area on these COM1 models so it’s well worth keeping the cooling pack nice and clean. On tractors with more than 12,000 hours on the clock, you should also take a look at the bolts on the manifold, which tend to break with age.

Another problem on the 924 and 926 models is the Bosch VP44 fuel injector pump. “After around 5,000 hours, the engines almost always lose power. To sort the injection it is time to refurbish the pump,” says Axel. He also advises checking the injectors on these tractors with over 10,000 hours and replace them if necessary (they are around €90 each). And the valves should also be adjusted regularly.

Two alternators

There are two alternators, one left and one right of the engine block. There are charge lights at the top of the dash, and another above the steering column, which will show whether both are working or not. The latter is for the right-hand alternator. These can be sourced from truck part suppliers for around €250 — an original Fendt-branded unit is closer to €800. At the same time, you should also check the belt tensioner for the powerband on the right side of the engine. Its bearings need regular lubrication.

Axel still has a slightly leaking air brake compressor on his 926 model to remedy. The compressor is flange-mounted to the spur gear housing and serves as the drive for the power steering pump.

“Repair kits are sadly in short supply, which is why I have a new compressor unit in the workshop waiting to be fitted,” he says. However, an original replacement costs about €3,000, so it’s a pricey part.

To meet the exhaust emissions at the time, oil vapours from the crankcase ventilation were fed into the intake manifold. After a lot of hours, this can lead to the intercooler getting clogged with soot. Traces of oil on the vent pipe connections will indicate if this is a problem.

“One way around this is to filter out this oil residue and then install an oil catcher in the ventilation line, something I am going to do to my 926,” says Axel Schnackenberg.

Naturally stepless

Turning to the familiar continuously variable transmission, which is an ML200. Since most of these tractors will now have well over 10,000 hours clocked, the question of a new transmission often crops up in operator conversations.

“If you find a 900 Vario model with 12,000 operating hours which still has the first transmission, then you can assume that the tractor has always been driven in a Fendt-friendly manner,” points out Axel. “People I know with comparable 900s are up to about 20,000 hours and still have the original transmission.”

It is possible to retrieve the maximum transmission pressure by pressing down the brake pedal – see the Fendt Favorit 700 Vario article in the 9/2024 issue of profi for a bit more on this.

Fendt experts are capable of calibrating the transmission (code 4007 in the workshop menu) on a stationary tractor with warm transmission oil and the hand throttle set to 1,800rpm. During the calibration job, the transmission automatically works through its characteristic curve. If the tractor is able to complete the calibration, then it is a good indicator everything is working properly. If it aborts the calibration, then there is a problem. Incidentally, the oil heats up faster when the tractor is travelling in reverse for an extended period of time than when driving forward.

If the transmission needs replacing, then Axel’s advice is to stump up the €14,000 or so for a refurbished unit from Fendt rather than simply changing some parts. However, there are engineering businesses that now offer overhauled Vario transmissions.

Powerful front axle

These tractors used a Dana 050F front axle so they are well equipped for heavy-duty applications. The beefy hubs need 34” front wheels with 12-stud rims. Typically wear occurs on the 900’s centre pivot pin which occasionally needs to be replaced. The good thing is that, in addition to the bushes in the front axle pivot, the bolts are also fitted with shrunk-on brass bushes. This design pretty much eliminates bolt wear.

“When I check a tractor, I jack it up using the front linkage with a ballast weight fitted,” says the engineer. “I can then inspect the kingpins or tie rod ends for play.”

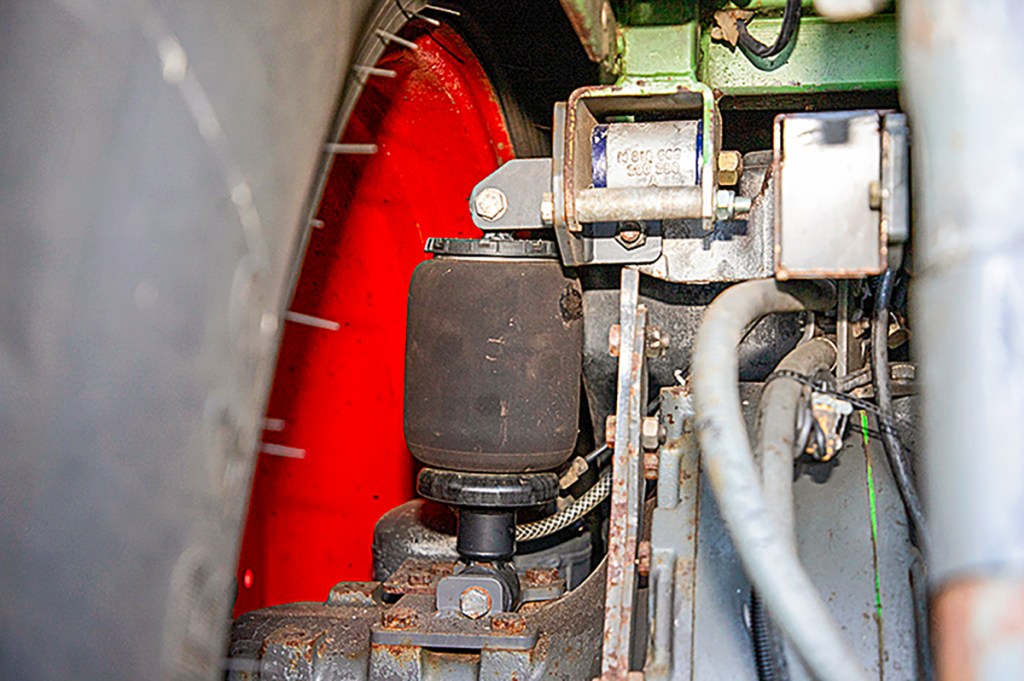

The 900’s front axle suspension is considered fairly robust. Problems are usually caused by leaking steering cylinders and the three nitrogen accumulators on the valve block located at the front right under the cab.

“In most cases, the suspension will have no effect.,” points out Axel. “You can either have the accumulators refilled or replace them as a full set for around €800 from aftermarket suppliers.”

If the original accumulators are still in good working order, and the suspension is still too hard, the covers on the connections can be removed.

The electro-hydraulic spool control valves are also located at the front right under the Fendt cab. There are usually four of them. As standard, they are supplied by an axial flow variable displacement pump delivering either 112l/min (up to 920) or 117l/min. The hydraulic oil is separate to the transmission oil. Occasionally you will hear of issues with the electronic valve control, so don’t be too surprised if you see evidence of previous repair work.

The three taps behind the cover switch the rear linkage from single- to double-acting and shut off the front linkage. A special feature is the third tap for adjusting the stand-by pressure of the closed centre hydraulic system from 20 to around 28 bar, which should influence the type of hydraulic response.

The control centre

Don’t let the number of membrane buttons for the pto speed get you over excited — although there are buttons for 540, 750 and 1,000rpm, buyers had to choose between 540 or 750. You need to select the pto speed each time you start the tractor. The familiar button to return to the previous settings is only available from COM2.

If you don’t have it, then retrofitting a front pto costs around €7,000. As standard, these tractors come with the control panel for the ‘comfort’ spec but that doesn’t mean that front ELC (Electronic Lift Control) is actually installed.

One small but significant difference to its successors relates to the familiar Go and End buttons on the drive stick. These can only be used to save individual functions, such as the linkage. COM2 introduced the Teach-In headland management pack as standard, allowing you to program a full sequence. Automatic functions for the pto, four-wheel drive or diff lock are also available on COM1 tractors.

Finally, you should compare the operating hours shown on the dash with those on the terminal. To see these, press the F1, F3 and F5 buttons simultaneously and switch on the ignition at the same time. If the readings differ, find the chassis number on the top of the instrument panel and compare it with those stamped on the tractor. If it differs, it has most likely been replaced.

How much is all the fun?

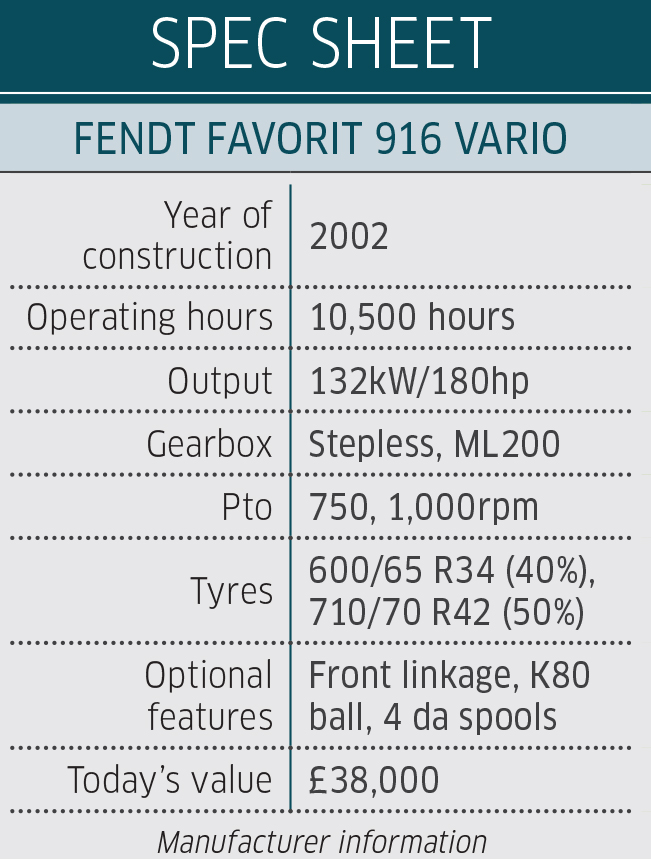

Due to the short three-year production run, these particular 900s are scarce on the used market. Decent Fendt 916 or 920 machines with more than 10,000 operating hours start at around £38,000+. If you’re looking for a 926 with a reasonable level of specification, like that owned by Axel Schnackenberg, the price will quickly exceed £35,000.

Alexander Bertling

For more up-to-date farming news click here and subscribe now to profi and save.