Fendt has redesigned its two-rotor rake line-up, adding new features such as the ProConnect concept with the FlexHigh and MyMemory features. We take a look.

KEEPING IT BRIEF

- The rotors on the new rakes benefit from an improved driveline and better suspension layout.

- ISObus-equipped models have additional auto functions such as adjusting the working height relative to the current forward speed.

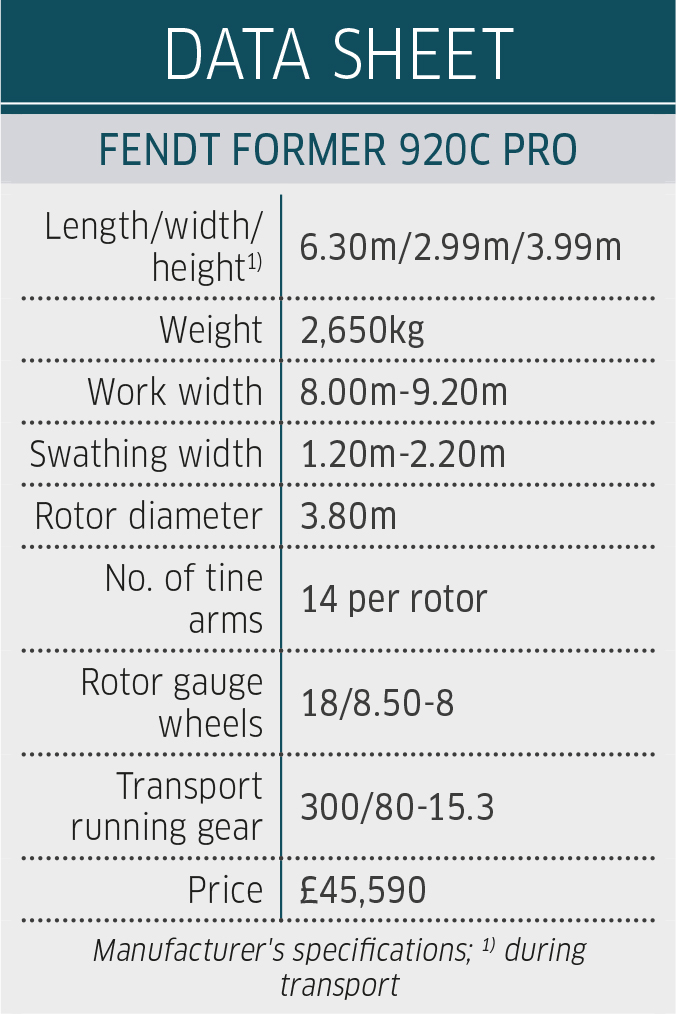

- The new 920C Pro model in full spec costs £45,590

- It’s also marketed as the Massey Ferguson RK TC Pro.

Fendt’s latest line of Former C centre-delivery, two-rotor rakes takes to the grass market as a quartet of machines with working widths spanning 6.90m to 10m. Rotor diameters start off at 3.30m, followed by 3.60m and 3.80m and go up to 4.10m with 12, 13, 14 and 15 tine arms, respectively.

While the smallest model, the 760C is only available in the ‘Standard’ spec, the largest model, the 1000C, only comes in Pro guise. The two mid-size rakes (the 860C and 920C) are offered in both versions. When coupled to an ISObus-compatible tractor, the Pro can be operated using the joystick and tractor terminal. A quick glance at the user interface reveals similarities to FendtOne.

The new rake not only incorporates the nifty Fendt SteerGuard steering system from its predecessor, but also the double swing arm with cardanic rotor suspension.

Rotors lift out parallel

A welcome new feature is how the rotor lifts out of work.

Initially, the rotors are raised up parallel to the ground and then fold upwards after reaching a certain height. This is reversed when lowering back into work to prevent the tines from poking into the ground.

The coil suspension springs on the arms have three tension settings, which can be changed without any tools, helping transfer weight from the rotors to the main frame and making it easier to adapt to changes on ground following.

Also doing their part is a tandem running gear option for the bogies under the rotors. These can be rigid or even come as a steered version.

Three-piece drive shafts

All four Former C rakes are equipped with a one-end wide-angle pto shaft as part of the standard specification.

For the large working width, the 960C and 1000C have a three-piece driveline between the gearbox and rotor — exactly the same arrangement as on the four-rotor Former 14055.

The same applies to the central gearbox, which is mounted on a hinged plate; this gives the driveline additional downward travel when the rake is put in its transport position. Even with all of the tine arms attached, the overall height of the 760C, 860C and 920C is still less than 4.0m. The 1000C needs arms removing.

Tine arm attachment was also a major topic for the designers. These are now fastened with bolts to handle the torsional forces. The arms can also be removed if required, such as when storing the machine.

Pro models with ISObus

We used the 920C Pro with ISObus controls. This spec has independent rotor lift-out as standard for precise working on wedged- shaped patches and on headlands.

Speaking of headlands, only the Pro models have a five-stage adjustable lift height for headland turning, which is tweaked on the terminal. Section control is also an option for these higher spec machines. When the tractor gives out the signal, the rotors lift automatically as they enter an area already rowed up.

More interesting, though, is the ProConnect with the FlexHigh and MyMemory functions. FlexHigh automatically adjusts the raking height relative to the current forward travel speed. As the forward speed increases, the tines work deeper; likewise when you slow down, working height is raised hydraulically. Depending on conditions, the raking height can be adjusted in three levels: soft, medium or aggressive.

MyMemory is the name of the integrated memory settings for the working width, swath width and raking height. This may sound a bit gimmicky, but, when you have finished rowing up, it allows the rake to fold into its most compact transport position at the touch of a button and resume the set position in the next field, again at the touch of a button. This reduces the risk of incorrect settings.

Other details

- The rotor tops are bolted, maintenance-free, and each one has its own overload protection.

- The working width indicator and the new hydraulic transport lock are visible from the cab.

- There is a hectare-and-hour counter.

- The electronic connector is now stowed in a weather-proof position.

- An automatically folding swath curtain is an option.

- Three LED work lights are available on the Pro models as an extra.

- Recommended list price for the Former 920C Pro is £45,590.

Summary

Fendt has redesigned its twin-rotor centre-delivery rakes, improving various details. And with the Pro version there’s the benefit of ISObus controls and some interesting new functions. For example, at the touch of a button the rotors fold from their lowest possible transport height to the pre-set raking width and height. In addition, the working height adjusts automatically to the current ground speed to further improve the quality of work.

Hubert Wilmer

For more up-to-date farming news click here and subscribe now to profi and save.