We were able to use the Fendt Rotana 160V XtraCut to make bales up to 1.60m throughout last summer. Read on to find out what we thought of it.

KEEPING IT BRIEF

- Optional bale weighing system is very precise.

- The tested the Rotana 160V XtraCut is also sold as the Massey Ferguson RB 4160V XtraCut.

- There is a rotor disengage system to allow the chamber to continue to make a bale when there is an intake blockage.

Take a close look at the Rotana, and those familiar with the Lely Welger pedigree will spot the breeding lines of the Wolfenbüttel factory. There have been a couple of notable tweaks to the reputable baler design since AGCO took over proceedings in 2017 and decided to add both the fixed and variable round balers (as well as the combi versions) to the Fendt and Massey Ferguson product ranges.

Last season we operated the Fendt-branded version of what it calls the Rotana 160V, a variable chamber machine that can produce bales up to 1.60m in diameter. There is also a 180, which logically makes a max 1.80m bale. Our test example, which we used for packing away straw, hay and silage, came in XtraCut guise, meaning it was equipped with 17 knives.

Attachment options

Starting up at the nose, it can be hitched on using a clevis or K80 spoon. A lower mounted hitch will be the most popular set-up for the UK and Irish market, but it can also be easily altered for top mounting.

The hydraulic hoses, the power supply, the ISObus cable and the brake lines are well supported and are easy to couple; the same applies to the Walterscheid pto shaft. The two-speed, crank-operated parking stand is on the left of the drawbar. Beside it is the folding ladder for providing safe access up to the platform when replacing the net roll.

The drive

540rpm pto is standard, with a 1,000rpm speed as an option (£1,977). After the pto, the drive is divided left and right in what Fendt calls the PowerSplit transmission. This gearbox forms part of the structural frame, helping it to reduce vibrations; indeed, the very smooth running is one thing we really noticed when piloting the Rotana.

On the baler’s right-hand side, you’ll find the driveline for the rotor and the pick-up, while on the left side you’ll locate the chains and sprockets that power the bale chamber. Here you’ll pick out one of the machine’s unique features, a 360° over-run slip clutch that ensures the chamber can run smoothly in the event of a sudden stop or blockage.

Powerful pick-up

Fendt uses a camless pick-up with five rows of tines, each with 34 tines that have an effective crop gathering length of 13cm. The shape of the bands is said to ensure smooth crop flow, and during the season we didn’t encounter any pick-up related blockages or bottlenecks.

Also doing its part to encourage an even crop flow is the tine delivery drop-off point, which is close to the rotor and the side augers. The crop press roller with flexible tine comb takes care of the preliminary work at the intake.

Our test machine sported the £798 optional hydraulic depth wheels that swing in and out of work. Compared to the manual fitted wheels we think this is money well spent, even more so if you are frequently changing fields. The baler’s gauge wheels have two well-designed hole patterns for altering the pick-up’s height. Another option (£1,849) is the pendulum system that allows 70mm up and down travel. Our test baler also had the wider, 2.40m pick-up (£3,306).

Keeping things moving

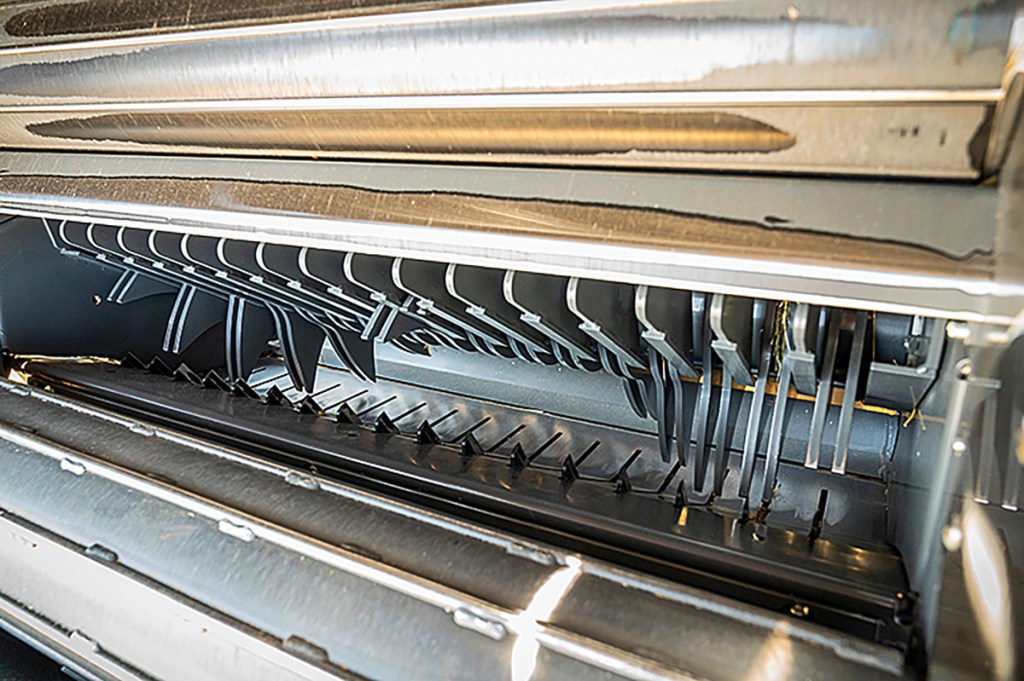

The Rotana is available as a simple conveyor rotor without a cutting unit, but, if you want to chop, there are 13-, 17- or 25-knife cutting systems. Our machine had the 17-knife unit (£7,954), which can be activated in groups of 0/8/9/17.

The 134rpm rotor proved it was capable of reliably feeding material from the pick-up through the knives and into the main bale chamber. Blockages are virtually eliminated because the nifty HydroFlexControl function allows the spring-loaded floor underneath the knives to drop when a blockage is about to happen. However, if things do go pear-shaped, you can step in and hydraulically lower the drop floor.

The ‘drop’ system consists of a pressurised hydraulic cylinder up on top and a strong suspension spring on the bottom. According to Fendt, the system automatically clears around 80% of all potential crop blockages. During our time testing the Rotana we very rarely suffered a blockage, even when we didn’t spot the occasional lump.

The XtraCut blades are hydro-pneumatically protected against overloads in two groups (eight and nine). With our 17 knives, the theoretical chop length is just under 68mm, which appeared to be well maintained.

AGCO has included a small but very helpful feature on the knives: you can increase the pressure temporarily to push the blades into position through clogged up slots — this is more of a get-out-of-jail card rather than regular practice. The more advisable path is to fit the optional blanking blade when you are not chopping.

Knife changes are done after unlocking and lowering the drop floor. A magnetic locking aid for each blade makes this operation a pretty straightforward task.

Horizontal bale start

The variable bale chamber consists of four endless belts, each 285mm wide and 8mm thick. There are also three rollers that form the floor and the front of the chamber. The belts wrap around several rollers. Both the drive chain and the belts themselves have large wrap angles around the sprockets or rollers, ensuring positive drive at all times — even in less favourable conditions.

For instance, in wet and heavy silage, we hadn’t any problems with belts slipping or similar issues. And bale starts, too, were always impressive. This is partly due to the chamber being very small at the beginning of the bale formation so that the rotor soon presses the material against the belts, which together with the rollers ensures a quick and reliable start. This bale-forming design also demonstrated its advantages in brittle straw.

Consistent baling pressure

The shape tensioning arm with its ‘Constant Pressure System’ ensures constant baling pressure – this can be continuously adjusted using the hydraulics. The Rotana also has an infinitely adjustable softcore function.

We particularly liked the OptiClean cleaning rollers: these are profiled rubber elements on the guide rollers, which bend and flex the belts to remove any material that may be sticking to them. AGCO reckons these are better cleaning spirals because the belts are not mechanically scraped clean. We can say the system works well; the belts stay clean. Nonetheless, every now and then you should check whether straw has wrapped around the rollers and remove it.

The rollers have solid bearings, which can come with auto-lube, a £3,739 option. Fendt points out this is a unique selling point. The standard alternatives are greasing banks. Regarding maintenance, that’s very easy and quick to sum up. The only thing that is not always a pleasure is blowing the machine down at the end of the day, because chaff collects in tight corners, which can be a pig to blow out.

Developed binding system

AGCO has further developed the netting unit and introduced the so-called chute tying system. This refers to a pivoting conveyor belt: when the bale is finished and the net is needed, the belt moves into its binding position and feeds the net into the chamber between the rollers, where it is trapped by the rolling bale, which then wraps itself automatically. This active feeding system worked perfectly in our tests, and the area is kept nice and clean by the moving belts.

The well-known and simple net guide with the centring pin for inserting and locking the roll in place hasn’t changed. There is room to store two spare rolls.

A spring-loaded and extendable bale ramp makes it easier for the bale to roll out of the chamber. On flat ground, the bale rolls far enough from the back of the Rotana that the door can close quickly without the risk of hitting the bale.

Hydraulics and operation

Our test machine was equipped with the ‘Bale Control Pro’ control system (£2,498). Together with the optional load-sensing system and the tested TIM Profi functions, this package brings some useful solutions — for instance, automatically opening and closing the tailgate, the automatically lifting pick-up during the weighing stage, the bale weighing system, optimised edge covering and lots more.

We operated the Rotana from the tractor terminal and the Bale Control Pro terminal (£2,495). The layout of the machine and its functions are well designed, and the menu navigation is simple to fathom. There are default settings for silage, hay and straw, which are usually in the right ballpark, but you can then customise them further.

All of the important parameters are there so you can just glance at the screen. The audible signals for bale shape and target diameter are customisable, too. The memory can log up to 20 customer/fields. The semi-automatic functions, such as the automatic tailgate control, can make the operator’s work that bit easier on long days; and the functions are very precisely coordinated.

TIM functions

Our machine was equipped with the TIM implement tractor control system, which, compared to the load-sensing version, costs £2,507 less (load-sensing costs £10,260). We’ve worked with TIM several times now and It really takes the hard work out of baling, especially for inexperienced operators, but also for those who have to make phone calls and manage the farm or business from the tractor cab.

But where there is good, there is also bad. And, for us, this is the complicated activation process. You have to make numerous tractor and baler settings as well as ensuring you have met various conditions. Those who don’t want to use TIM can operate the baler in the conventional, convenient manner.

Bale shape and density

During the test we did our usual throughput and performance measurements, baling dry wheat straw from a straw walker combine. We set the baling pressure to 80% and the bale diameter to 1.60m. The average bale weight was a respectable 305kg and was finished in a good 43 seconds. On average, the rear door takes about four seconds to open and close — which is fast and living up to Fendt’s Speed door claim.

Bale shape is also perfect. However, we have to criticise the precision of the diameter settings, which you shouldn’t rely on and you really do need to check. Although you can calibrate, we found the settings were not consistently maintained.

By comparison, the weigh system (included in the TIM package) is very precise and our measurements were exactly in line with the weights displayed. The system uses three weigh cells: two on the axle and one on the drawbar. As noted already, the baler pick-up is raised automatically during weighing to avoid any errors.

Summary

AGCO has developed the tried-and-tested Welger and Lely round balers and equipped them with features such as the chute binding and semi-automatic functions as well as TIM capability. The level of technology obviously has a price, yet the Rotana 160V Xtra with its 17-knife cutting system performed very well in our practical test, and our criticism mainly revolved around minor issues. The throughput in straw is very good, as is the density. It reliably baled silage, even under less than ideal conditions.

In full spec, it costs a good £85k, which is a chunk. The entry-level price is an easier to digest £55,000. Comparing the specs, It’s good to keep this in mind: the bales produced are the same — it’s the working speed and comfort that are the difference.

Christian Brüse

For more up-to-date farming news click here and subscribe now to profi and save.