To make the most of the extra horsepower from the new Jaguar 1000 series, Claas has also developed wider headers. We tucked the 14-row Orbis into some Italian maize in the autumn to see if the big Jag could devour the claimed 500 tonnes per hour.

KEEPING IT BRIEF

- The longer chassis of the bigger Jaguar 1000 series means no additional ballast is needed.

- Two gauge wheels support the Auto Contour.

- We were able to achieve throughputs of 300 to 500t/hr in maize.

With the extra power now on tap from its Jaguar 1200 forager, Claas has come up with both new grass pick-ups and maize headers that can help to make the 1,100hp forager sing.

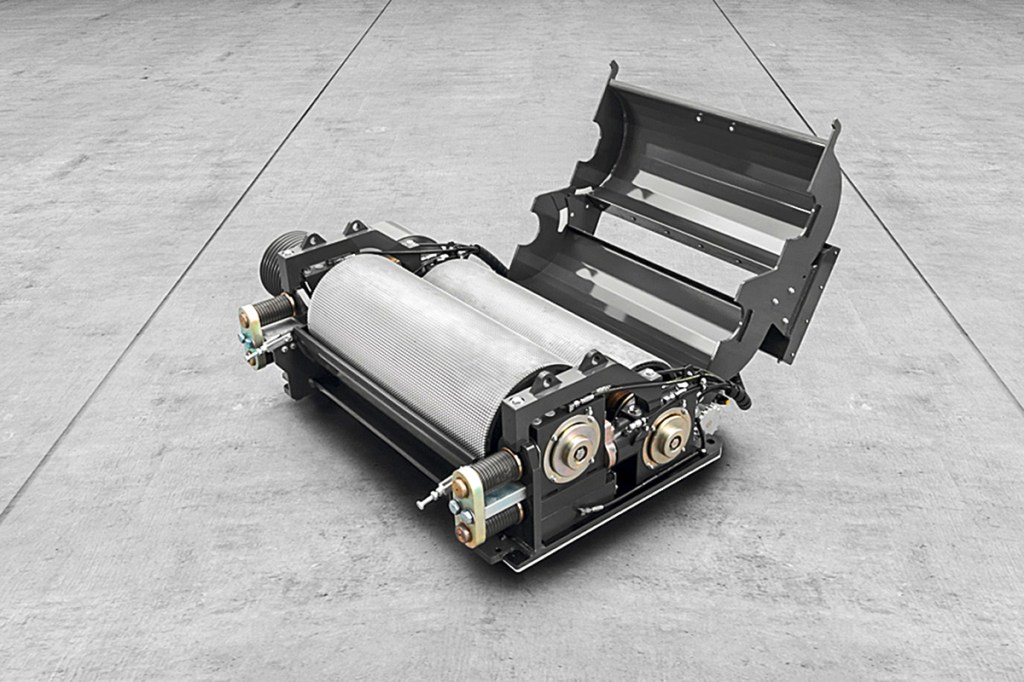

One of the most noticeable features is the pendulum frame, which creates an interface without any moving parts and a massive passageway for the crop to flow into the machine. Even at first glance it is easy to see that this machine is capable of handling a lot of material.

With the new CEMOS Auto Header function, the header speed automatically adjusts to the ground speed and chop length. The driver can preselect the speed difference between the tines and auger (Pick-up) or drums and feeder cones (Orbis).

New Pick-up

Customers can choose between three Pick-up models, which differ only in their working width (2.62m, 3.60m and 4.19m), although the 2.62m will be the default fit in Britain and Ireland. The design team has been able to do away with chain drives and clutches. Instead, power is transmitted by a pto shaft or gearbox, with the tines driven by a oil-filled cam track gearbox.

The intake auger is pressurised hydraulically and, according to Claas, acts like a fifth pre-compression feed roller. This extra bit of pre-compression of the crop is reckoned to add to throughput.

14-row maize header

The Orbis is available as a 9.0m (12 rows) or 10.50m (14 rows). To ensure an even feed to the 910mm wide crop flow channel, the entrance has been made bigger. The Orbis 9000 now only uses large drums, whereas the 10.50m Orbis 10500 gains two small drums.

The drive speed is twice as fast as that on the Jaguar 900, resulting in less torque, and therefore less strain, on the components especially on start-up. Crop flow through the header is designed to be as straight as possible. Thinner guide rails inside the crop flow channel reduce resistance, while using Hardox steel ensures durability.

To further reduce equipment downtime, a ‘Premium Line’ range of wearing metal parts is available for the new Orbis heads. Then there are the wear indicators that show the user the current condition of the guide bars. This will help owners to better manage any downtime when it comes to replacing worn components.

The design of the existing Orbis 750 and 900 was adapted when developing the new wider Orbis 9000 and 10500. The central section has its own separate frame and is also much stronger and there is less chance of it flexing, which allows the scrapers on the feed cones to be set a lot tighter.

The outer wings also benefit from separate frames that utilise steel ropes to transmit the forces in as straight a line as possible.

Header height control is handled by three AutoContour feel bars. On the big 14-row header unit, a couple of actively controlled stabiliser wheels aid with contour following; these automatically move into their working position as soon as the auto-height control is activated.

The variable drive allows the knife speed to be significantly increased if required —for instance, in lodged maize or wholecrop silage. The scrapers underneath the knives ensure the stubble is shredded properly, which is very good for getting the stubble to break down, especially across mainland Europe where they are battling the costly corn borer beetle. To ensure no cobs are lost on their longer journey through the wider header, nets along the top of the headers are now being fitted to keep the crop from making a break over the top.

Converting to lodged maize

The familiar lodged maize augers are gone. Instead, the side panels can be removed so that the outer stars can aggressively work through the lodged crop. Also, the cob traps and the guide fingers in front of the drums can be individually removed. Special tips are available for lodged maize; these simply replace the standard points.

Homologated for road travel

Folding is done in the same way as the other Orbis models. The 10.50m wide Orbis folds down to a transport width of 3.30m. The 9.0m unit measures 3.0m wide when ready for the road. The optional protective safety features, including road lighting, still fold automatically. Where limits are stringently enforced there is the separate chassis to distribute the weight. Transport System (TS) is standard for the UK and Ireland on all 1000-series Orbis. The Jaguar 1000-series doesn’t need any extra rear-end ballasting, and the 10-inch transport wheels are now larger than before.

Easy service and maintenance

The pick-up’s strippers are easy to remove, and the tine holders can be quickly detached as there is only one screw to undo. Two bubble levels on the Orbis help to check the oil level. Useful colour markings indicate which gearbox needs to be checked in which position.

The header is automatically detected and the settings adjusted. The drive shaft and locking systems are still mechanical. There is a multi-coupler for the hydraulics.

Harvesting maize in Italy

The north Italian maize was yielding 55-75t/ha with strong cobs, so, with the dry matter at 33%, we couldn’t have timed our visit any more perfectly. With the chop length set to 5mm, the Jaguar 1200 was able to trundle up and down the field at around 5km/hr, filling up the 50m³ push-off trailer with 21 tonnes of maize in 4 mins and 15 seconds. This equates to a throughput of 298 tonnes per hour if you don’t factor in any headland turning time.

The corn cracker was set to 3.2mm and the accelerator at 50mm. The short chop length costs power: when we set it to 12mm, the machine managed 7.5 to 8.0km/hr. With this setting, we theoretically achieved the 500t/hr that Claas is shouting about — again those headland turn times are not included.

The chopping quality was excellent. Our machine had the shredlage cracker installed. We were able to consistently drive at the limit of the machine’s performance (130% engine load or 1,500 rpm), with the 24-litre motor recovering quickly when overloaded. The automatic header stop function gives the operator the confidence that the forager can be pushed on hard. The new Orbis was providing a constant flow of material into the Jaguar, the header speed continuously making automatic adjustments.

There was the occasional cob loss, though nothing out of the norm. A lot of crop trash collects on the header, but the chopper pilot did make a point of it being a quick cleaning job. The uniform stubble indicated optimal header height control. The Jag operator also praised the trouble-free operation in weedy crops.

The monster forager made life at the clamp rather hectic — three large tractors were busy distributing and compacting the crop being delivered by a fleet of a dozen trailers.

Summary

Claas has developed a new range of high output grass and maize headers to make the most of the Jaguar 1000 series foragers. But they are not just bigger, because the engineering team also focused on crop flow and maintenance. Harsewinkel will not be offering a direct-cut wholecrop header when series production starts.

NEW CRACKERS

Claas also adapted the corn cracker to the new model. The roller diameter has increased to 310mm, while the crop flow width is 752mm. As usual, the conditioning intensity can be infinitely adjusted from the cab by increasing or decreasing the gap between the rollers.

Customers can choose between the MCC-XL-Classic-fine (grain), the MCC-XL-Classic-medium (maize 3.5mm to 22mm chop length) or the MCC-XL-coarse (maize with 5mm to 27mm chop length) models. The models differ in the number of teeth on the rollers (188, 157 or 123 teeth). The default speed difference is 40%, while the machine is supplied with a pulley that reduces it further to 30%. The pulley for 50% difference is available as an accessory.

The MCC XL shredlage is also available for the 1000 model. This has 137/188 teeth and a speed difference of 50%. It is particularly suitable for longer chop lengths (18 to 30mm).

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.