Last spring we were able to gain some first-hand experience with a four-row Prios Pro, Grimme’s latest planter.

KEEPING IT BRIEF

- The Prios Pro is at the top end of the Grimme planter range.

- Operators benefit from a wide range of setting options.

- In the field, the machine can transfer plenty of weight to the wheels, but the wheel load should be comparable to previous models.

Grimme’s latest potato planter is the multi-pronged Prios, bringing with it new features such as the optional swan neck drawbar, the universal or hybrid ridging bodies and, for the first time, section control for all components.

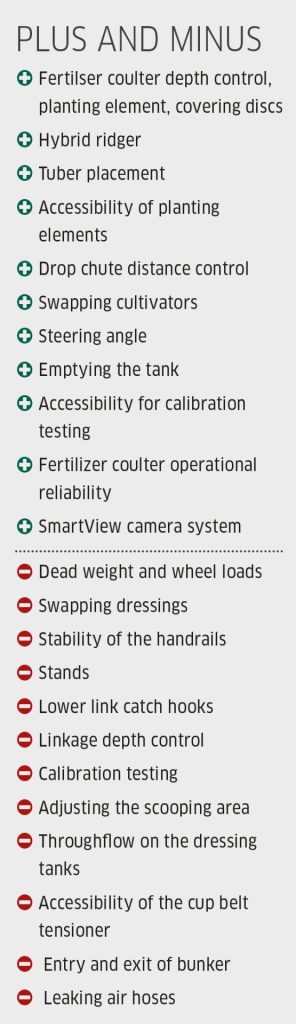

On the Prios Pro — that’s the model with the swan neck drawbar — hitching up is made much easier when the cultivator is removed. This gives the user more room to connect the headstock to the tractor’s rear linkage (Cat. III/IV) as well as the Power Beyond connections and a double-acting spool for the linkage on the planter.

As a useful side note, Cat II or III couplers are available for mounting different tillage equipment — in our instance, this was an Amazone power harrow. Unfortunately, the bolts holding the hook ends to the arms worked their way loose several times on the test machine, which was not ideal, to put it mildly.

As this linkage doesn’t have any integrated depth control (at least not for the moment) it’s best that the cultivator has its own depth control such as the crumbler roller. And because they are linkage mounted, different cultivators can be very quickly and easily swapped over — great. The drawbar can be telescoped both in and out to accommodate different length cultivators. Thanks to the ball coupling above the headstock, planter manoeuvrability is outstanding.

The parking stands on the main headstock are neither nice to use nor sturdy enough, despite most of the weight resting on the Prios parking stand farther back.

Moving on to the fertiliser applicator, the easy-to-operate roll-up tarp and accessibility are very good. The plastic grids inside the tank are also impressive. The system can cope with large application rates.

You do have to make sure to set the sense of rotation of the augers correctly.

Calibration testing is half good

To calibrate, you first swivel the transfer point of the metering unit into the fertiliser tubes on both sides. Just do not forget to put them back afterwards, otherwise the fertiliser isn’t going to reach the coulter and there is no sensor there to warn you.

Our operators would like to have had external controls here, also for the calibration trays. The optional calibration kit should also come with a larger folding bucket. Grimme hasn’t ruled out adding external controls in the future. Fill and empty level sensors will be available for the coming season and can even be retrofitted which is good news. At the moment, the amount of fertiliser in the hopper has to be visually checked, which is only possible with cameras, as the inspection windows are hidden on both sides.

The volume-optimised funnels do require regular cleaning to avoid dust building up, and the same applies to the areas where the granules enter the hoses.

Large disc coulters

The operators liked the spring-loaded disc coulters (570mm) running on either side of the tubers. They also liked the depth control and the robust fertiliser inlet in the coulter. All of the usual planting depths were easily achievable during the test.

Familiar dressing system

On the TS820 dressing system, the drawer-like folding steps are very delicate compared with the other steps on the Prios. This also applies to the rickety handrails, as well as those above the planting elements. The rate was controlled relative to the current forward speed on the dressing system, which had issues maintaining the system’s pressure when running empty. Even after refilling, this problem persists for minutes after.

Grimme wants to meet the demands for a throughflow between the 400-litre tanks as part of an update to the dressing system. Then switching between furrow and tuber treatment should be possible without tools. As for fittings and accessibility, these tick all the boxes.

Top-notch depth control

The coupled depth control of the fertiliser coulters, furrow openers and the covering discs is operator-friendly. All of the units are hydraulically suspended down from the main frame and raise out of work. The depth of the fertiliser coulters is set relative to the planting element by refitting a pin.

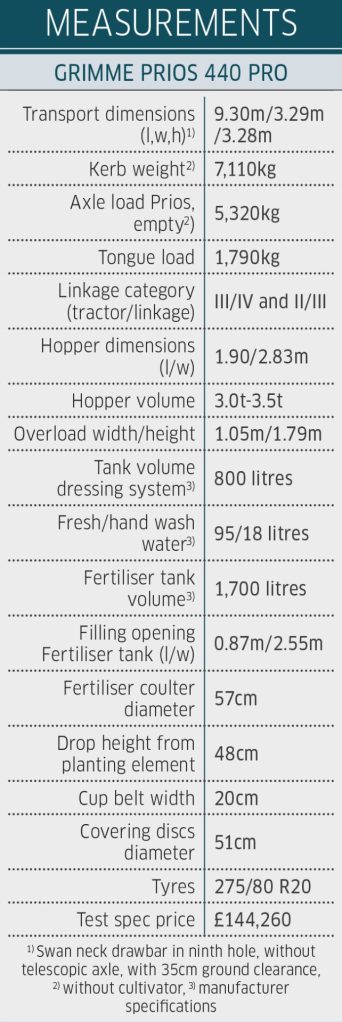

The depth or position of the covering discs can be adjusted from the terminal. Since all of the components are suspended, we didn’t identify any compaction issues under the furrow opener, for example. The drawback, however, is that the wheels carry the entire weight. The 275/80 R20 tyres are more than sufficient for the job, but 280s are available as an option.

Unladen and without a cultivator, axle weight is about 5.3t. With up to 3.5t of potatoes, 800 litres of water and a max of 1.8t of fert, the load is proportionally increased.

The planting quality and accessibility of the planting element were impressive. Due to the lack of space, it is a little more difficult to manually fill the cup belts. This would be safer if they were filled by an automatic system that switches off the hopper lifting mechanism when the ladder is down.

A few words on the hybrid ridger at the rear of the machine: this is a complex structure, which, combined with the various different types of control system, is very versatile and forms large ridges with firm walls. Yet a huge amount of spannering is likely to be needed after impacting a foreign object. The moulded PE parts look relatively strong and durable.

Operating the CCI1200 and IBX-200 control boxes in the cab is something you can get used to, even though the fully customizable keys do not make for intuitive operation.

Summary

The Prios Pro offers many options, which also entail compromises, such as the weight. Grimme will probably rework the parking stand on the headstock and the product flow between the dressing tanks. With a price tag in the region of £144,260, it is only fair that these things are tip top.

BRIEF TEST

We didn’t have the capacity to test this machine as intensively as usual and couldn’t, for example, make any tuber placement tests. Still, we thought you’d like to read about the diverse experiences at one of our test farms.

Sönke Schulz

For more up-to-date farming news click here and subscribe now to profi and save.