Since last year, GST has been offering its rotary hose with an optional seeder

and front hopper. We check out the 12m combination in action.

KEEPING IT BRIEF

- Front hopper capacity is 2,700 litres, but this can be increased to 4,000 litres as an option.

- Two fans generate 6,000-8,000 litres of air per minute.

- Most of the GST machines are sold directly from the Danish factory.

Since 2019, the Danish manufacturer GST has been offering rotary hoes ranging in working widths from a mere 1.50m all the way up to 15m. But it built its very first machine in 2013 for use on the company’s own farm. Recently the firm added its own front hoppers, which are reckoned to make the rotary hoe even more versatile and increase its efficiency — for applying fertiliser, reseeding grassland or even sowing catch crops.

The structure

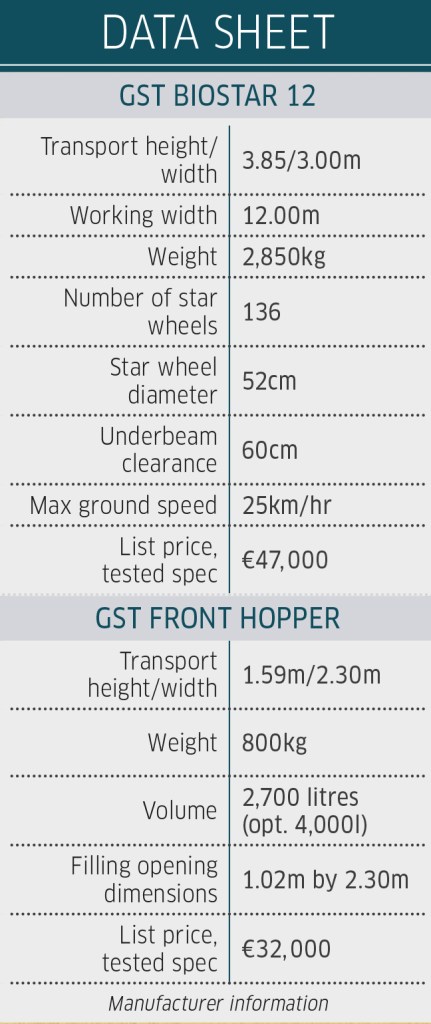

The 2,850kg Biostar 12 rotary hoe has Cat. III couplers just like the front hopper.

Both the lift arms and top link have three attachment height options, allowing users to not only adjust the height but also the aggressiveness and the ground pressure. Further adjustments are made by adjusting the top link.

The massive frame carries 136 star wheels spaced 8.5cm apart. Frame height is specified as 60cm. Each of the 52cm diameter wheels has 15 buckets riveted to the wheels like spokes. GST offers a lifetime guarantee on the hardened hoe wheels. The star wheels are individually spring-loaded and can be pressurised with up to 40kg.

Maintenance-free bearings are mounted on stainless steel axles and are double-sealed, according to GST. As for grease points, there are only a handful on the folding mechanism to visit.

The piston rods of the hydraulic cylinders are hardened and also double-sealed. GST says this eliminates the need for a stone guard, but it is still an option if you want it. Two double-acting spools are required for folding, and two pins need fitting as a belt and braces transport locking system. Gauge wheels are available as an option (€4,000). However, the manufacturer advises against them, arguing that the machine carries itself well even on hilly ground.

Other options include wheel holders (€22 each), which hold individual star wheels in a raised position when operating in row crops. Another option in the price list are scrapers (€42 each) for stony conditions.

The front hopper

If you want to operate the 2,700-litre front hopper (€32,000), you also need to order the optional distribution heads. From here transparent tubes run to the stainless steel spreading plates, which are spaced 50cm apart. These clear hoses permit you to view the seed flow from the cab. Theoretically, GST could also supply an electronic seed monitoring system, although that’s likely to be prohibitively expensive.

The hoses are tidily routed. You can pull the hoses off the splash plates without any tools if there happens to be a blockage.

The front hopper volume can be increased up to 4,000 litres (€2,000) and can be split 50:50 for holding different seeds. The seed metering units then mix the two types of material in the air flow — a solution that could save the cost of premixed seed.

To enable application rates of 5 to 300kg/ha at speeds up to 20km/hr, GST installs four metering units and two fans for an air flow of 6,000 to 8,000 litres per minute as standard. The seeding shafts can be quickly removed and fitted with modular metering wheels or blank caps depending on sowing rate. There is a practical storage box for the spares when not being used.

Calibration testing

For filling the hopper through the 1.02m x 2.30m opening, there is a sturdy fold-down step, which doubles as a protective guard for the metering unit when folded up, with two gas struts making it easy to handle. The lid of the vacuum hopper is nicely sealed with four sturdy clips.

The front hopper is operated via ISObus: enter the seed rate and the forward speed, and then simply press the remote press switch to start calibration. After that, enter the calibrated weight to the terminal and the software computes the rate per pulse. The machine then adjusts itself using these values. After calibrating one metering unit, you can simply copy the result to the other three units. The entire electronic system is sourced from Müller.

Tractor adaptation

Each of the two fans needs its own double-acting spool and a return line. Should your tractor’s front linkage lack the necessary number of spools, GST can route the pipes to the rear alongside the seed hoses down the side of the cab as an extra cost option. In that case, the machine is delivered with all of the brackets that will hold the two 115mm diameter seed pipes. A fitter from the factory will fit these when the machine is being installed.

Quick couplers for connecting the supply lines are not available yet, but these are being developed. Once available, they will make attachment and removal of the front hopper and the hoe a quick affair.

The 800kg front hopper is entirely steel and painted. As for road transport, there are six standard LED work lights, cameras as well as dipped and high beam headlights plus indicators — exemplary! You can also fit an APV spreader instead of the front hopper.

Field work

We tucked the combination into several fields on a dairy and arable farm — 25mm of rain had fallen shortly before work began. On the first day we worked a field of five-year grass leys. Although the soil (60 index points) was very hard after persistent rain, the hoe managed to loosen the soil enough. The Biostar is simple to adjust, and working speeds of up to 20km/hr were possible.

On the second day of the test, the job was to incorporate barley stubble and sow a cover crop. Here the calibration test really tested our patience: GST needs to simplify the setting options on the ISObus display; secondly, the chart showing the appropriate seed rollers was missing.

However, once we were set and the seeding seed shafts were kitted out properly, the calibration test was quick and easy. We spread 28kg of a mix of perennial ryegrass, red clover, incarnate clover and bastard ryegrass — again at 20km/hr. To suit, we were able to cover 25 hectares per hour. We didn’t change any of the settings from the previous day, except for the top link that we adjusted to increase the pressure.

Intercrop seeds, weed seeds and volunteer cereals were properly covered with soil and the crust was broken up. Neither the weeds nor the crop stubble were removed, and the tramlines weren’t levelled. The robust, tough design and high-quality base specification are stand-out features.

Summary

The GST Biostar can be used universally and flexibly on different tasks. When paired with the nifty front hopper, fertiliser or seeds can be applied effectively. The design is sturdy; set-ups are easy.

Ordered in the described specification, the price is €79,000.

Sebastian Rüther

For more up-to-date farming news click here and subscribe now to profi and save.